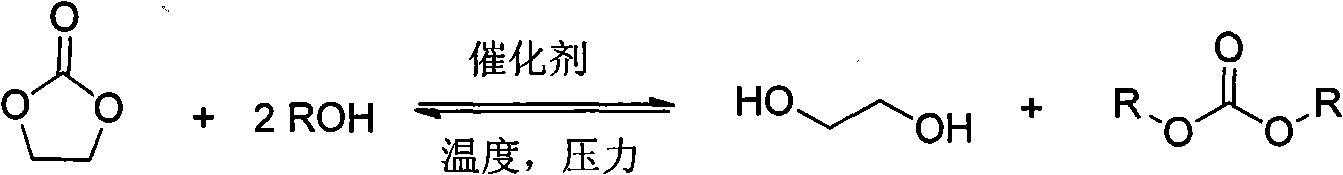

Method for simultaneously preparing glycol and carbonate by catalysis

A technology of ethylene glycol and carbonate, applied in chemical instruments and methods, preparation of organic carbonates, preparation of oxygenates, etc., can solve problems such as harsh reaction conditions, low equilibrium conversion rate, and reduced alcohol activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

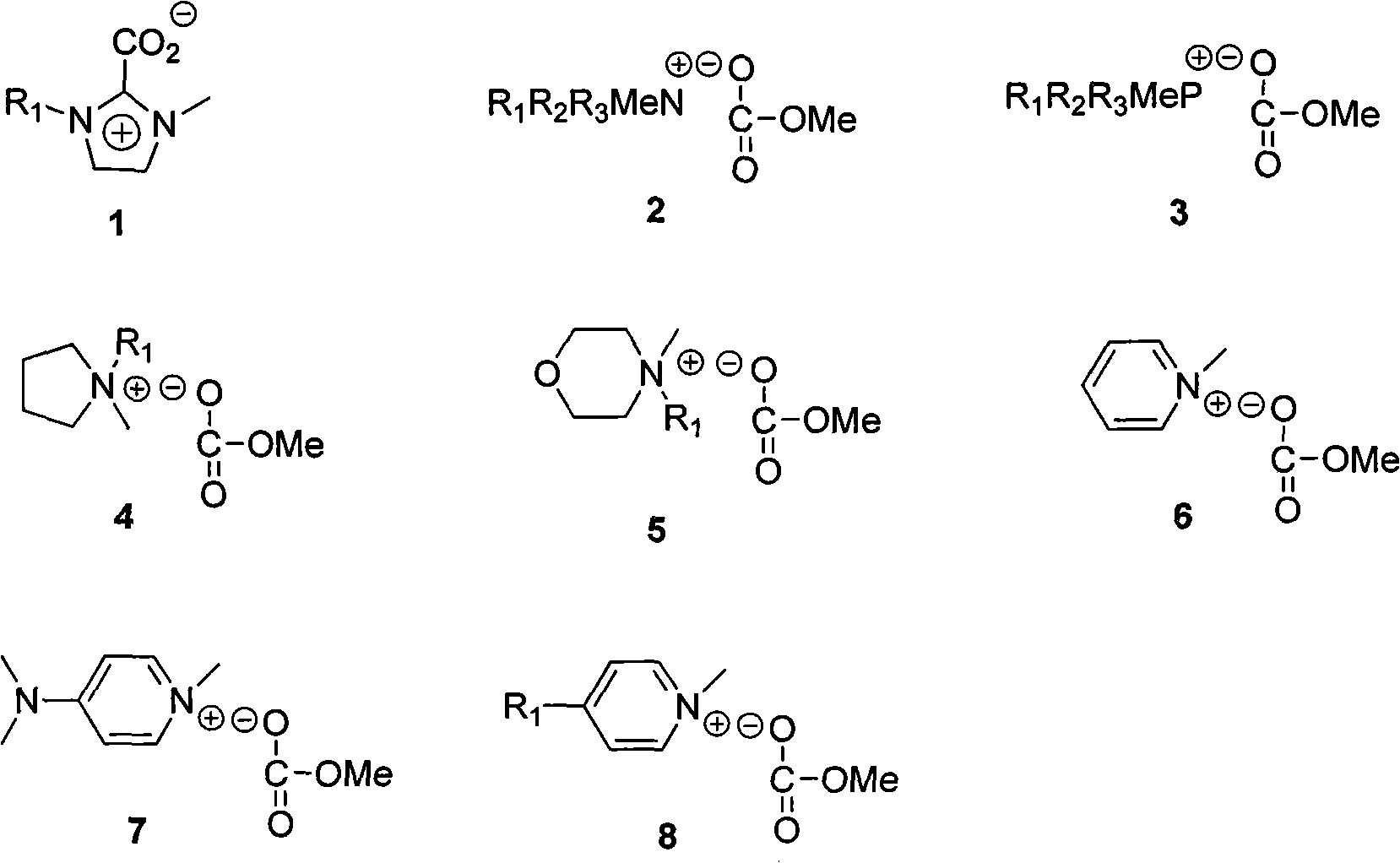

[0013] The first type of basic catalyst takes the synthesis of 1,3-dimethylimidazole-2-carboxylate as an example: in a 100mL reactor, add 15mL dimethyl carbonate and 10mL methylimidazole, under the protection of nitrogen, the temperature The reaction was carried out at 120°C for 24 hours, and the resulting solid was recrystallized with methanol to obtain white 1,3-dimethylimidazole-2-carboxylate.

[0014] Type 2-8 basic catalysts are triethylmethylammonium methyl carbonate [(C 2 H 5 ) 3 CH 3 NCO 3 CH 3 ] As an example: in a 100mL reactor, add 17.8g of dimethyl carbonate, 20g of triethylamine and 20g of methanol, at a temperature of 120℃, react for 12h, distill off unreacted raw materials, and use methanol for the remaining solid Recrystallization gave white triethylmethylammonium methyl carbonate.

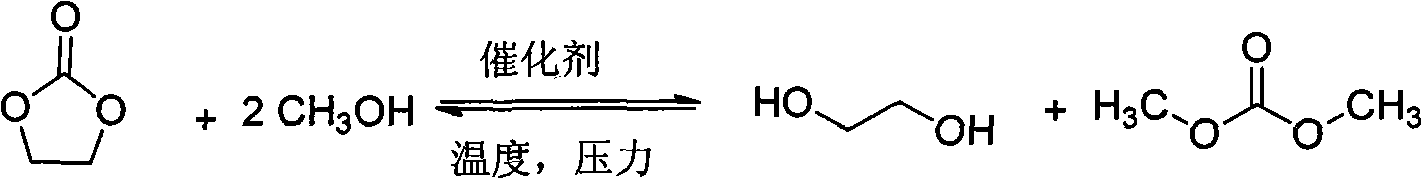

[0015] The method of the present invention for catalyzing the simultaneous preparation of ethylene glycol and carbonate is illustrated by the following examples, but the present inventi...

Embodiment 3

[0017]

[0018] Implementation method: In a 100mL stainless steel autoclave, add 1.2mmol of catalyst 1,3-dimethylimidazole-2-carboxylate, 10.5g (0.12mol) of ethylene carbonate and 38mL (0.96mol) of methanol, and seal the reactor. The temperature was slowly raised to 383K controlled by a temperature controller, the pressure was 0.3MPa, the reaction was for 1 hour, and then cooled to room temperature. The resulting mixture was analyzed by gas chromatography. The conversion rate of ethylene carbonate was 72% and the selectivity of ethylene glycol was 99%. The selectivity of dimethyl carbonate is 99%.

Embodiment 4

[0020] Same as Example 3, the catalyst used was tributyl methyl ammonium methyl carbonate [(C 4 H 9 ) 3 CH 3 NCO 3 CH 3 ], the amount of the catalyst is 1.2 mmol, the others remain unchanged, the conversion rate of ethylene carbonate is 60%, the selectivity of ethylene glycol is 98%, and the selectivity of dimethyl carbonate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com