An addition type potting glue for wind turbines and its manufacturing method

A wind power generator and additive technology, applied in chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of flame retardancy of silicone potting adhesives, difficulties in practical application, and two-component Addition-type silicone rubber bonding performance and other issues, to achieve excellent bonding performance, good protection, excellent salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

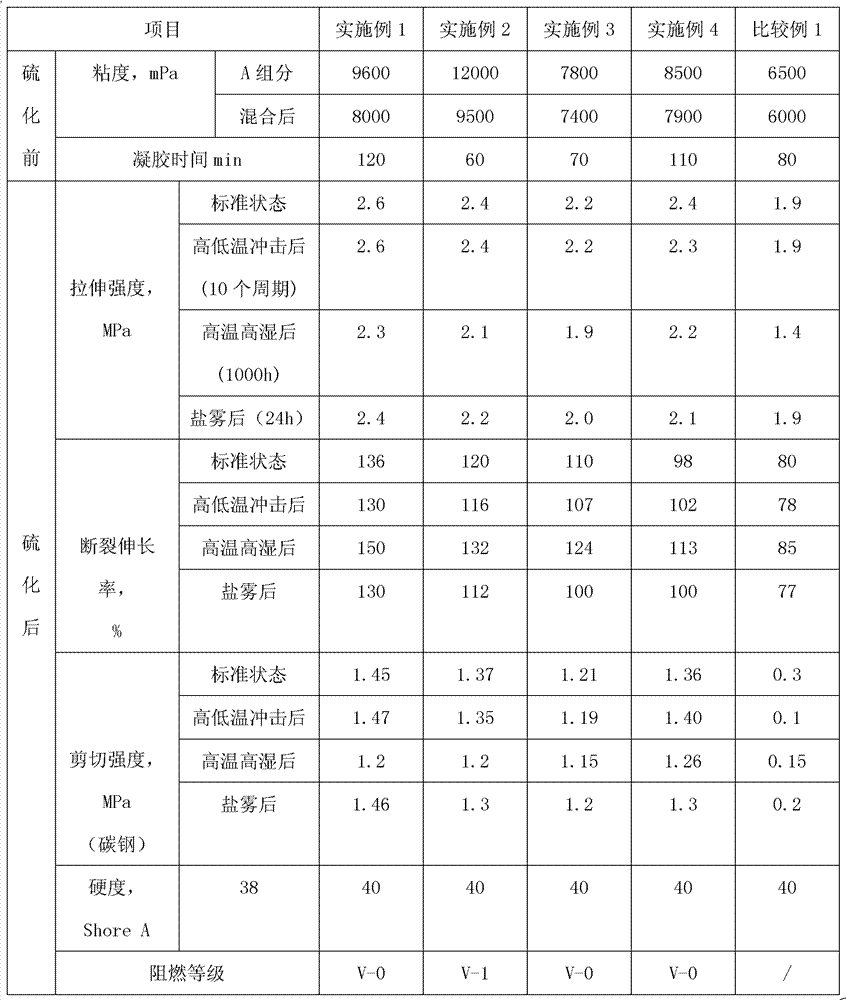

Examples

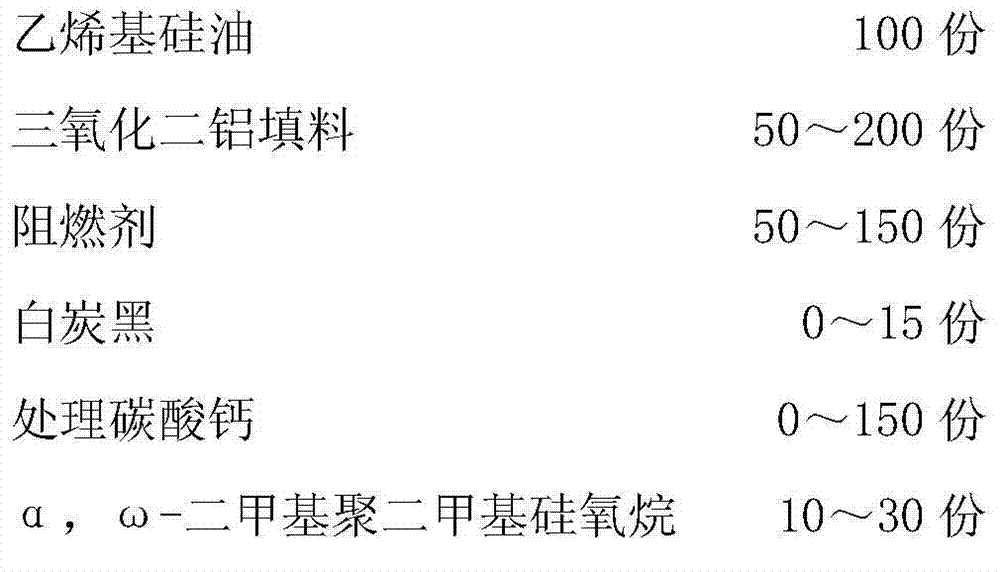

Embodiment 1

[0060] 100 parts by mass of vinyl silicone oil with a viscosity of 5000mpa·s at a temperature of 25°C, 200 parts by mass of aluminum oxide, 100 parts by mass of aluminum hydroxide, and 20 parts by mass of α,ω-dimethyl polydimethylsiloxane Parts, 15 parts by mass of white carbon black was added into a vacuum kneader, at a temperature of 170° C., a vacuum degree of 0.06 mpa, dehydration and blending for 30 minutes to obtain a base material. 1 mass part of hydrogen-containing silicone oil with a hydrogen content of 0.8%, and 100 mass parts of base material were stirred and mixed for 30 minutes to obtain component A; 6 mass parts of vinyl siloxane chelate of chloroplatinic acid were 0.2 parts by mass of boric acid ester, CH 2 =CHSi(O CH 2 CH 2 OCH 3 ) 3 0.2 parts by mass, 0.2 parts by mass of titanium complex and 100 parts by mass of base material were stirred and mixed for 30 minutes to obtain component B; after mixing 5 parts by mass of component A and 1 part by mass of comp...

Embodiment 2

[0062] 100 parts by mass of vinyl silicone oil with a viscosity of 3000mpa·s at a temperature of 25°C, 200 parts by mass of aluminum oxide, 50 parts by mass of a flame retardant, 30 parts by mass of α,ω-dimethylpolydimethylsiloxane Parts by mass, 5 parts by mass of white carbon black, and 150 parts by mass of treated calcium carbonate were added to a vacuum kneader, and dehydrated and blended for 120 minutes at a temperature of 120°C and a vacuum of 0.099mpa to obtain a base material. Add 3 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 0.8%, and 0.01 part by mass of methyltris(methylbutynyloxy)silane into a mixer and mix with 100 parts by mass of the base material for 20 minutes to obtain component A; With 4 mass parts of vinyl siloxane chelates of chloroplatinic acid, the structural formula is 1 mass part of tackifier, 1 mass part of titanium complex, and 100 mass parts of base material were stirred and mixed for 30 minutes to obtain B componen...

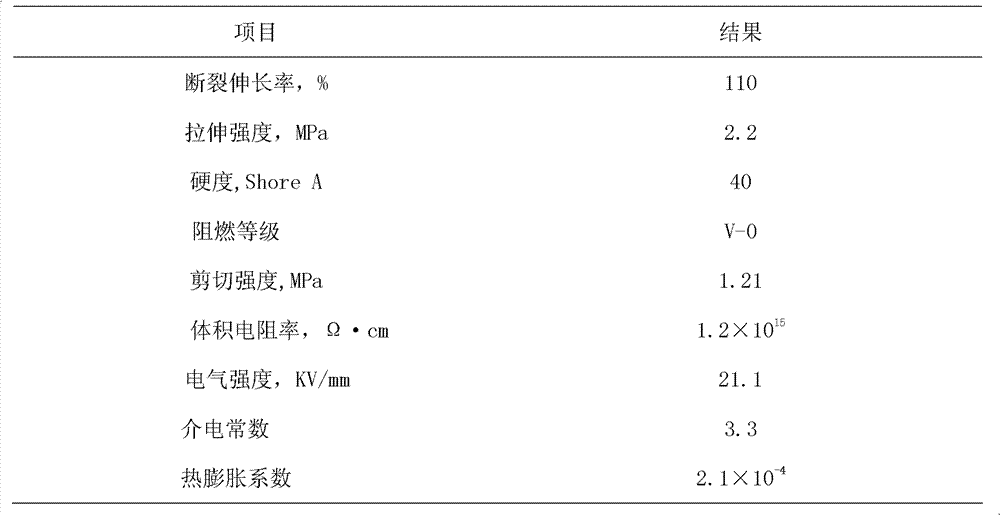

Embodiment 3

[0064] Add 100 parts by mass of vinyl silicone oil with a viscosity of 1000mpa·s at a temperature of 25°C, 150 parts by mass of aluminum oxide, 150 parts by mass of a flame retardant, and 100 parts by mass of treated calcium carbonate into a vacuum kneader, α, ω- 10 parts by mass of dimethylpolydimethylsiloxane were dehydrated and blended at a temperature of 150° C. and a vacuum degree of 0.06 mpa for 30 minutes to obtain a base material. Add 4 parts by mass of hydrogen-containing silicone oil with a hydrogen content of 0.25%, and 0.06 parts by mass of methyltris(methylbutynyloxy)silane into a mixer and mix with 100 parts by mass of the base material for 30 minutes to obtain component A; 2 parts by mass of platinum catalyst using aluminum oxide as a carrier, the structural formula is Add 0.5 parts by mass of tackifier, 0.2 parts by mass of borate ester, 0.1 part by mass of titanium complex, add to a mixer and mix with 100 parts of base material for 20 minutes to obtain compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com