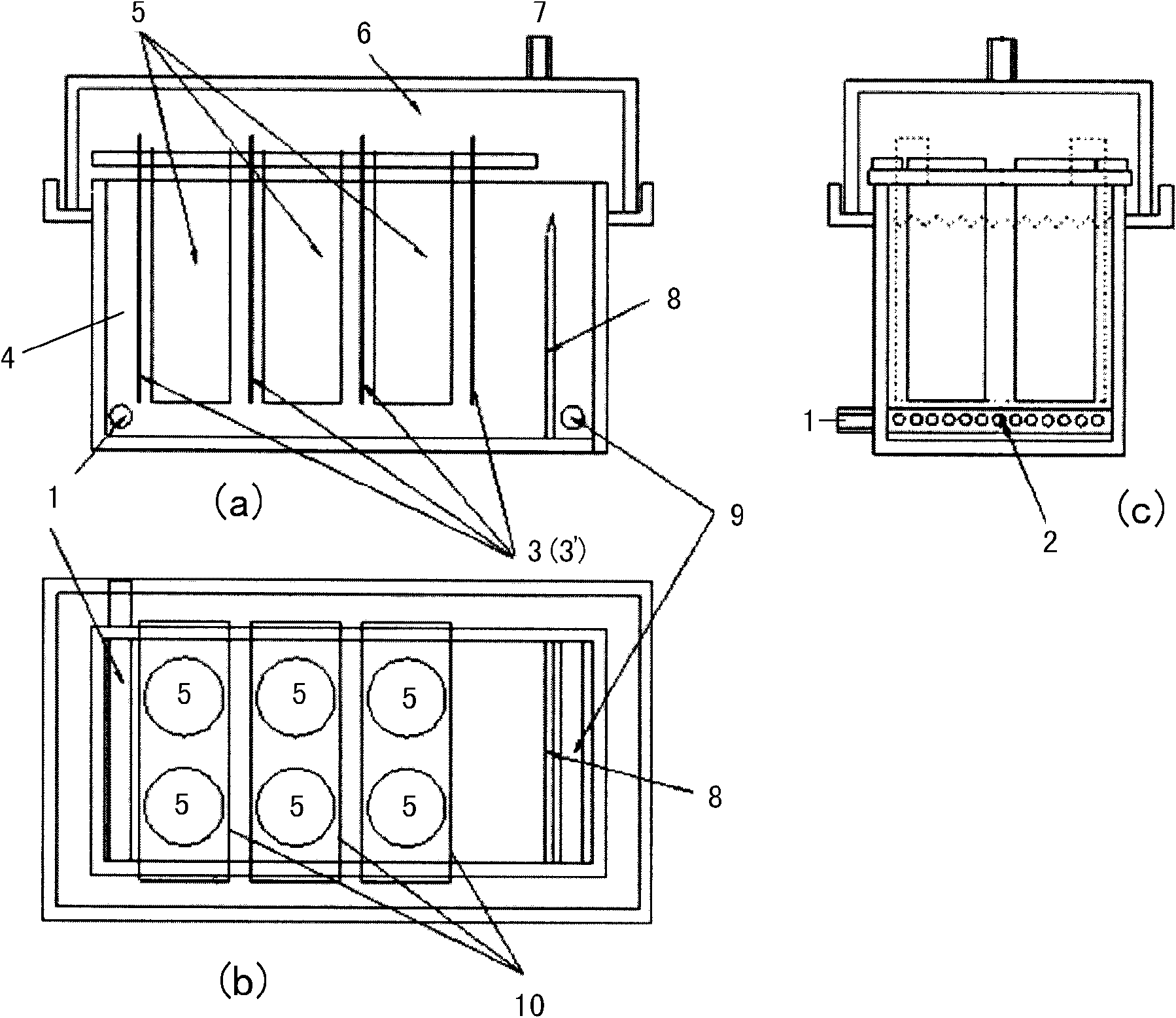

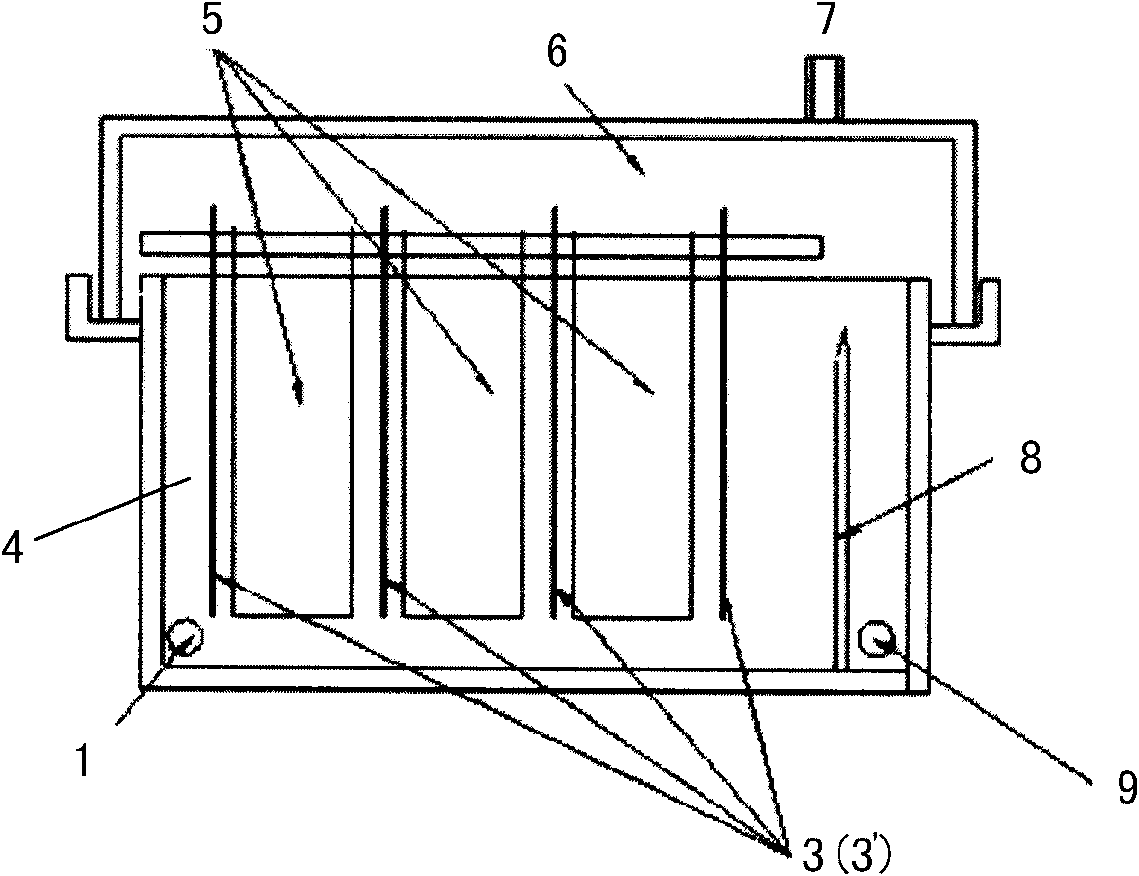

Method and device for treating cyanide-containing wastewater through photoelectrochemistry

A photoelectrochemical, cyanide wastewater technology, applied in chemical instruments and methods, oxidized water/sewage treatment, light water/sewage treatment, etc., can solve the problems of low reaction tank efficiency, easy passivation, unstable electrodes, etc. And the effect of simple maintenance, small installed capacity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The method and device for treating cyanide-containing wastewater described in the present invention are used to treat certain cyanide-containing electroplating comprehensive wastewater. The concentration of cyanide in wastewater is 15.8mg / L, Cu 2+ Concentration 10.1mg / L, Ni 2+ The ion concentration is 0.8mg / L, and the pH is 0.8. Firstly, the pH value of the wastewater was adjusted to 10.5, and then the photoelectric oxidation reaction was carried out. The volume of the reaction tank is 15L, and the apparent current density is 4A / m 2 , the UV light intensity is 10mW / cm 2 . The concentration of added sodium chloride is 2g / L, the residence time of wastewater in the photoelectric reaction system is 15 minutes, the concentration of cyanide in wastewater after treatment is 0.33mg / L, Cu 2+ The concentration is 0.1mg / L, Ni 2+ The ion concentration is 0.15 mg / L and the pH is 7.8.

Embodiment 2

[0060] The method and device for treating cyanide-containing wastewater described in the present invention are used to treat cyanide-containing and copper-containing wastewater generated during the production process of an electroplating plant. The concentration of cyanide in wastewater is 30.7mg / L, Cu 2+ Concentration 20.5mg / L, pH 1.2. Firstly, the pH value of the wastewater was adjusted to 10.3, and then the photoelectric oxidation reaction was carried out. The volume of the reaction tank is 15L, and the apparent current density is 5A / m 2 , the UV light intensity is 30mW / cm 2 . The concentration of added sodium chloride is 2.5g / L, the residence time of wastewater in the photoelectric reaction system is 20 minutes, the concentration of cyanide in wastewater after treatment is 0.21mg / L, Cu 2+ The concentration is 0.08mg / L, and the pH is 7.8.

[0061] The invention effectively removes the cyanide in water through electrochemical anode direct oxidation, photocatalytic oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com