Method for preparing silicon dioxide aerogel by using alcohol amine as alkaline catalyst

A silica and catalyst technology, applied in the field of inorganic porous materials, can solve the problems of high industrial production cost, limited popularization and use, and slow drying, and achieve the effects of fast drying rate, shortened preparation cycle, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

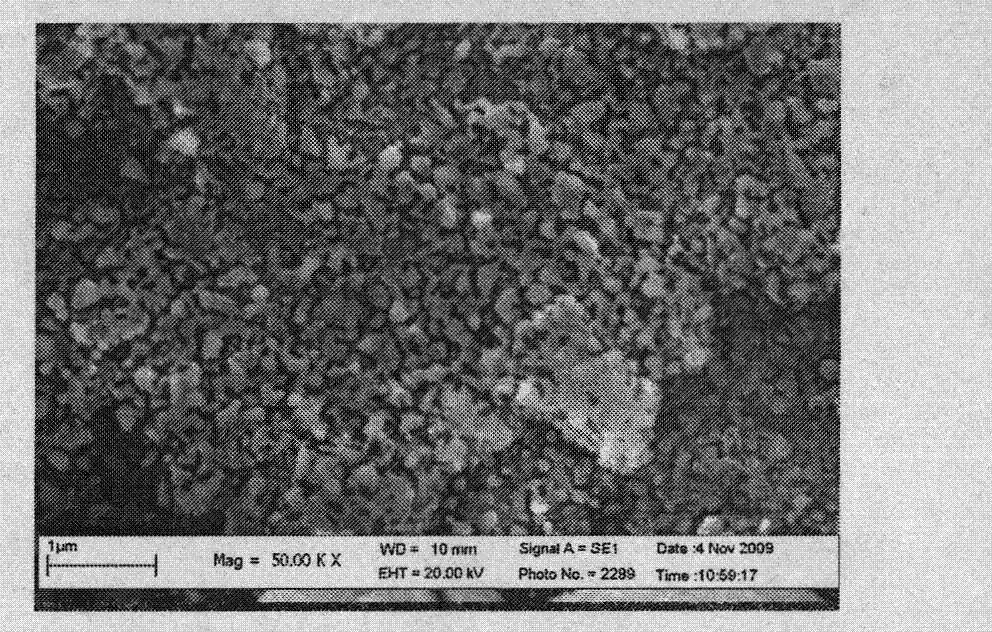

Image

Examples

Embodiment 1

[0022] Pour TEOS, absolute ethanol, and deionized water into a plastic beaker at a molar ratio of 1:3 to 10:3 to 10, mix well, and add 0.5 to 3ml of hydrochloric acid (0.8 to 2%, v / v ), after stirring for 1-5 hours, slowly add 1-5 ml of monoethanolamine solution dropwise (mono-ethanolamine: deionized water=1:5-20, v / v). After gelling, place it in a water bath at 60°C for aging, replace the original solvent with acetone every 24 hours, and take it out after 3 to 5 days. Put it in a vacuum drying oven at a vacuum degree of 3×10 4 Drying is carried out under Pa environment. The temperature was raised every 5°C by means of a temperature program, from 40°C to 60°C, and each temperature segment was maintained for 1 hour. The porosity of the prepared airgel is greater than 87%, and the specific surface area is 724.63m 2 / g, the pore volume is 1.36cm 3 / g, the average pore diameter is 14.75nm.

Embodiment 2

[0024] Pour TEOS, absolute ethanol, and deionized water into a plastic beaker in a ratio of 1:3 to 10:3 to 10, mix well, and add 0.5 to 4ml of hydrochloric acid (0.8 to 2%, v / v), after stirring for 1 to 5 hours, slowly add 1 to 5 ml of diluted diethanolamine dropwise (diethanolamine: deionized water = 1:2 to 10, v / v). After gelling, place it in a water bath at 50°C for aging, replace the original solvent with absolute ethanol every 24 hours, and take it out after 3 to 6 days. In vacuum degree 4×10 4 Drying is carried out under Pa environment. The temperature was raised every 5°C by means of a temperature program, from 25°C to 50°C, and each temperature segment was maintained for 2 hours. The porosity of the prepared airgel is >84%, and the specific surface area is 625.41m 2 / g, the pore volume is 1.44cm 3 / g, the average pore diameter is 12.03nm.

Embodiment 3

[0026] Pour TEOS, absolute ethanol, and deionized water into a plastic beaker in a ratio of 1:3 to 10:3 to 10, mix well, and add 0.5 to 3ml of hydrochloric acid (0.8 to 2%, v / v), after stirring for 1-5 hours at normal temperature and pressure, slowly add 1-5 ml of diluted diglycolamine (diglycolamine: deionized water = 1:2-4, v / v) dropwise. After gelling, place it in a water bath at 60°C for aging, replace the original solvent with absolute ethanol every 24 hours, and take it out after 3 to 6 days. In vacuum degree 7×10 4 Drying is carried out under Pa environment. The temperature was raised every 5°C by means of a temperature program, from 25°C to 50°C, and each temperature segment was maintained for 2 hours. The porosity of the prepared airgel is >80%, and the specific surface area is 427m 2 / g, the pore volume is about 1.25cm 3 / g, the average pore diameter is 11.56nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com