Cobalt-nickel-molybdenum-potassium (Co-Ni-Mo-K) catalyst for preparing low carbon alcohol by synthetic gas and preparation method thereof

A low-carbon alcohol, cobalt-nickel-molybdenum technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of low selectivity and no large-scale production equipment, and achieve high selectivity, high Active and stable, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

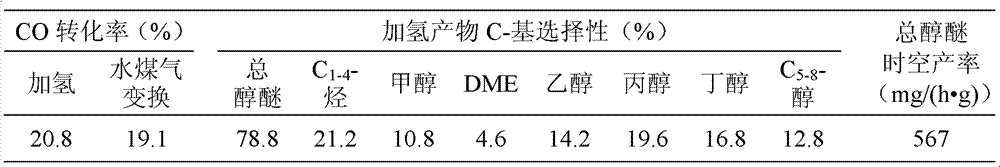

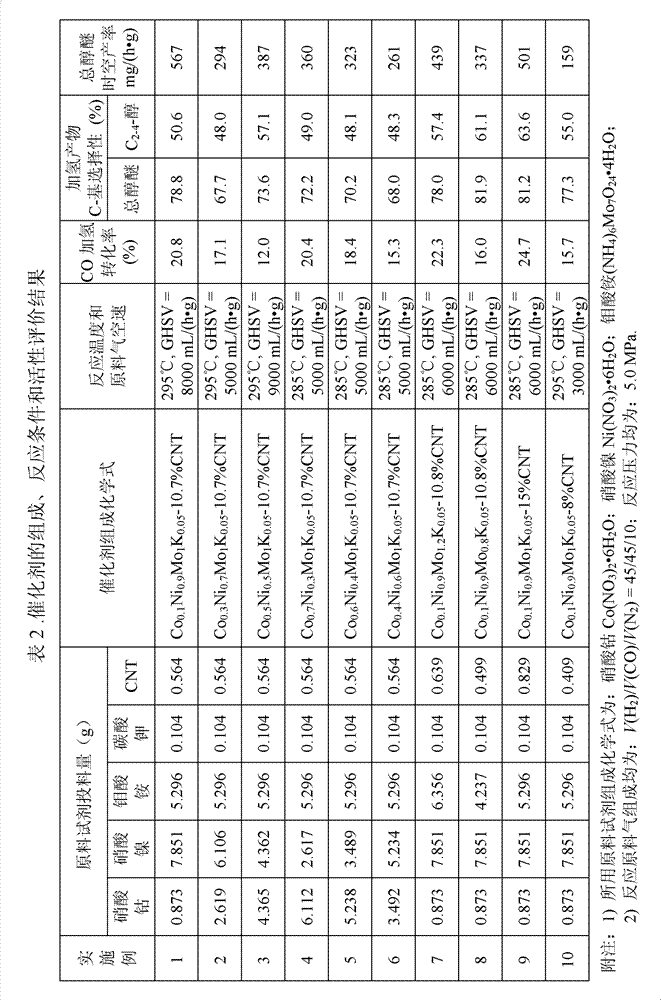

Embodiment 1

[0020] At a temperature of 85°C, 0.873g of Co(NO 3 ) 2 ·6H 2 O, 7.851g of Ni(NO 3 ) 2 ·6H 2 O and 5.296g of (NH 4 ) 6 Mo 7o 24 4H 2 O (the purity is all AR grade) was dissolved in 200mL deionized water, mixed evenly and added to a glass container pre-installed with 0.564g CNT, after stirring for 2 hours, ammonia water was added dropwise under strong stirring to precipitate precipitates and adjust and maintain The pH value of the solution is in the range of 6.4 to 6.7. Stop heating and stirring after 5 hours, and let it cool down to room temperature naturally; 2 Roast at 575°C for 4 hours in the atmosphere, and then add 0.104g of potassium carbonate (K 2 CO 3 , purity is AR grade) aqueous solution impregnated on the calcined precipitate, let it stand for 24 hours, and then dried at 110°C for 12 hours, pure N at 400°C 2 Roasting in the atmosphere for 4h, the chemical expression is Co 0.1 Ni 0.9 Mo 1 K 0.05 - Catalyst (oxidation state) of 10.7% CNT.

[0021] The ...

Embodiment 2

[0026] At a temperature of 85°C, 2.619g of Co(NO 3 ) 2 ·6H 2 O, 6.106g of Ni(NO 3 ) 2 ·6H 2 O and 5.296g of (NH 4 ) 6 Mo 7 o 24 4H 2 O (the purity is all AR grade) was dissolved in 200mL deionized water, mixed evenly and added to a glass container pre-installed with 0.564g CNT, after stirring for 2 hours, ammonia water was added dropwise under strong stirring to precipitate precipitates and adjust and maintain The pH value of the solution is in the range of 6.4 to 6.7. Stop heating and stirring after 5 hours, and let it cool down to room temperature naturally; 2 Roast at 575°C for 4 hours in the atmosphere, and then add 0.104g of potassium carbonate (K 2 CO 3 , purity is AR grade) aqueous solution impregnated on the calcined precipitate, let it stand for 24 hours, and then dried at 110°C for 12 hours, pure N at 400°C 2 Roasting in the atmosphere for 4h, the chemical expression is Co 0.3 Ni 0.7 Mo 1 K 0.05 - Catalyst (oxidation state) of 10.7% CNT.

[0027] The...

Embodiment 3

[0029] At a temperature of 85°C, 4.365g of Co(NO 3 ) 2 ·6H 2 O, 4.362g of Ni(NO 3 ) 2 ·6H 2 O and 5.296g of (NH 4 ) 6 Mo 7 o 24 4H 2 O (the purity is all AR grade) was dissolved in 200mL deionized water, mixed evenly and added to a glass container pre-installed with 0.564g CNT, after stirring for 2 hours, ammonia water was added dropwise under strong stirring to precipitate precipitates and adjust and maintain The pH value of the solution is in the range of 6.4 to 6.7. Stop heating and stirring after 5 hours, and let it cool down to room temperature naturally; 2 Roast at 575°C for 4 hours in the atmosphere, and then add 0.104g of potassium carbonate (K 2 CO 3 , purity is AR grade) aqueous solution impregnated on the calcined precipitate, let it stand for 24 hours, and then dried at 110°C for 12 hours, pure N at 400°C 2 Roasting in the atmosphere for 4h, the chemical expression is Co 0.5 Ni 0.5 Mo 1 K 0.05 - Catalyst (oxidation state) of 10.7% CNT.

[0030] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com