Preparation method of graft copolymer for surface sizing

A technique of graft copolymer and surface sizing, which is applied in the direction of water-repellent addition, paper, textiles and papermaking, etc., which can solve the problems of low grafting rate and poor overall performance, and achieve good storage stability and improved Paper tensile strength and tear resistance, effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of modified starch aqueous solution: Add 7000kg of water into the reactor equipped with stirring, turn on the stirring, slowly add 2000kg of oxidized starch and 1kg of α-amylase, raise the temperature to 70°C for 30min, then raise the temperature to 95°C, and then lower the temperature to below 85°C.

Embodiment 2

[0035] Preparation of mixed monomer A: Weigh 250kg of styrene, 98kg of butyl acrylate, and 0.4kg of methylstyrene dimer, and put them into a stirring reactor respectively, and mix evenly; replace with nitrogen to remove air.

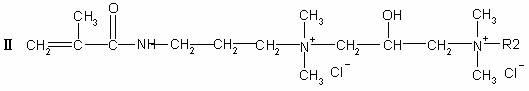

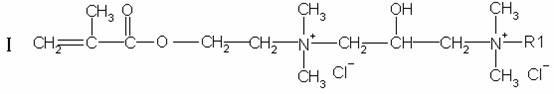

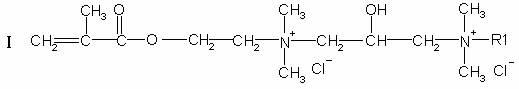

[0036] Preparation of mixed monomer B: Weigh 30kg of water, 30kg of DMAPMA, 2.5kg of MBAM, 20kg of PMDQ-14, and 4kg of acrylamide, and put them into a reactor equipped with stirring, mix well, dilute with 13kg of industrial hydrochloric acid, and then add to the reactor to adjust pH; remove air by nitrogen displacement.

[0037] Put 850kg of modified starch aqueous solution and 0.025kg of calcium acetate into the polymerization kettle, replace the polymerization kettle with nitrogen to remove the air, heat up to 90°C under stirring, add 12kg of Quab-342, add 132kg of 5% sodium hydroxide aqueous solution in 10 minutes, and then keep warm 30min; Add 15kg of glacial acetic acid, dissolve 1.2kg of ferrous sulfate with a small amount of water and add it to th...

Embodiment 3

[0040]Preparation of mixed monomer A: Weigh 250kg of styrene, 30kg of methyl methacrylate, 60kg of butyl acrylate, and 0.4kg of methyl styrene dimer, and put them into a stirring reactor, mix well, and replace with nitrogen Remove air.

[0041] Preparation of mixed monomer B: Weigh 30kg of water, 20kg of DM, 2.5kg of MBAM, 15kg of DMDQ-14, and 4kg of acrylamide, put them into a reactor equipped with stirring, mix well, dilute with 13kg of industrial hydrochloric acid, and add to the reactor to adjust For pH, remove the air by nitrogen displacement.

[0042] Put 850kg of modified starch aqueous solution and 0.025kg of calcium acetate into the polymerization kettle, replace the polymerization kettle with nitrogen to remove the air, raise the temperature to 85°C under stirring, add 15kg of Quab-426, and add 132kg of 5% sodium hydroxide aqueous solution in 10 minutes , and then keep warm for 30min. Add 15kg of glacial acetic acid. Dissolve 0.8kg of ferrous sulfate with a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com