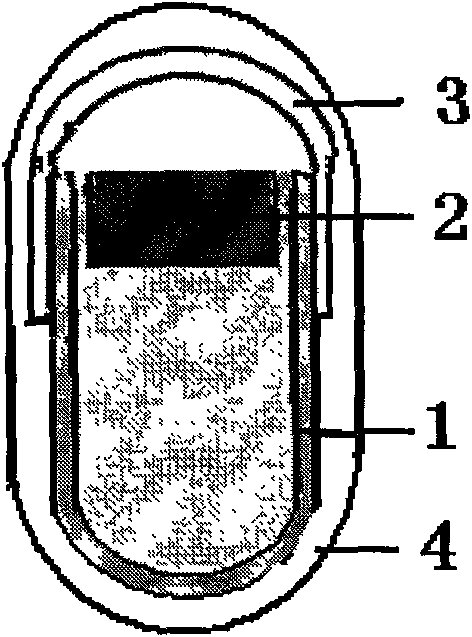

Novel capsule colon-specific drug delivery system (CSDDS) and preparation method thereof

A technology of colon targeting and drug delivery system, which is applied in the field of medicine, can solve the problems of difficulty in ensuring accurate release of drugs to the colon, poor effect of colon targeting and controlled release, complex prescriptions, and complicated processes, and achieves convenient and controlled drug release. The effect of clear explanation principle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Insoluble microporous membrane vesicle composition:

[0051]

[0052] Preparation process: first dissolve polyethylene glycol and poloxamer in acetone, then dissolve cellulose acetate in acetone, add an appropriate amount of titanium dioxide into it, stir well, and let stand to remove air bubbles. The insoluble microporous membrane capsule is obtained by making blanks through the dipping process, drying, shelling, cutting and finishing.

[0053] The composition of enzymolysis rubber stopper:

[0054]

[0055] Preparation process: mixing pectin, chitosan, ethyl cellulose and magnesium stearate evenly, adding them to a tablet press for tableting, and preparing a pectin sheet with a diameter of 5 mm, a hardness of 5.5 kg and a thickness of 0.9 mm, that is, Enzymatic rubber stopper.

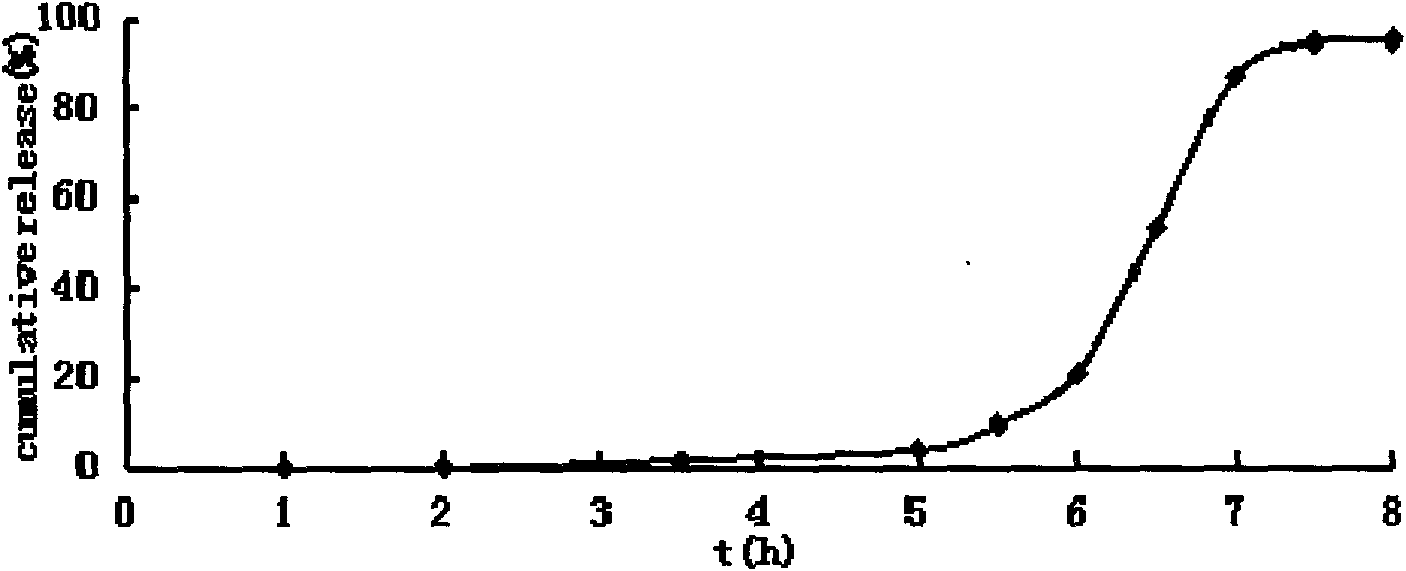

[0056] Take epirubicin hydrochloride as the model drug, mix the drug:sodium chloride=2:1, the drug is 10mg, fill it into the capsule in the form of powder, add an enzymatic pectin plug...

Embodiment 2

[0062] Insoluble microporous membrane vesicle composition:

[0063]

[0064] Preparation process: firstly, polyethylene glycol-400 and polyethylene glycol-4000 are dissolved in a mixed solvent of acetone: anhydrous ethanol (4:1), and then cellulose acetate is dissolved in the above mixed solution, and the dipping process is the same as Example 1, drying, shelling, cutting and finishing to obtain insoluble microporous membrane capsules.

[0065] The composition of enzymolysis rubber stopper:

[0066]

[0067] Preparation process: Mix pectin, chitosan and magnesium stearate evenly, add them to a tablet press to press, and prepare a pectin sheet with a diameter of 5mm, a hardness of 5.5kg and a thickness of 0.9mm, which is an enzymatic rubber stopper .

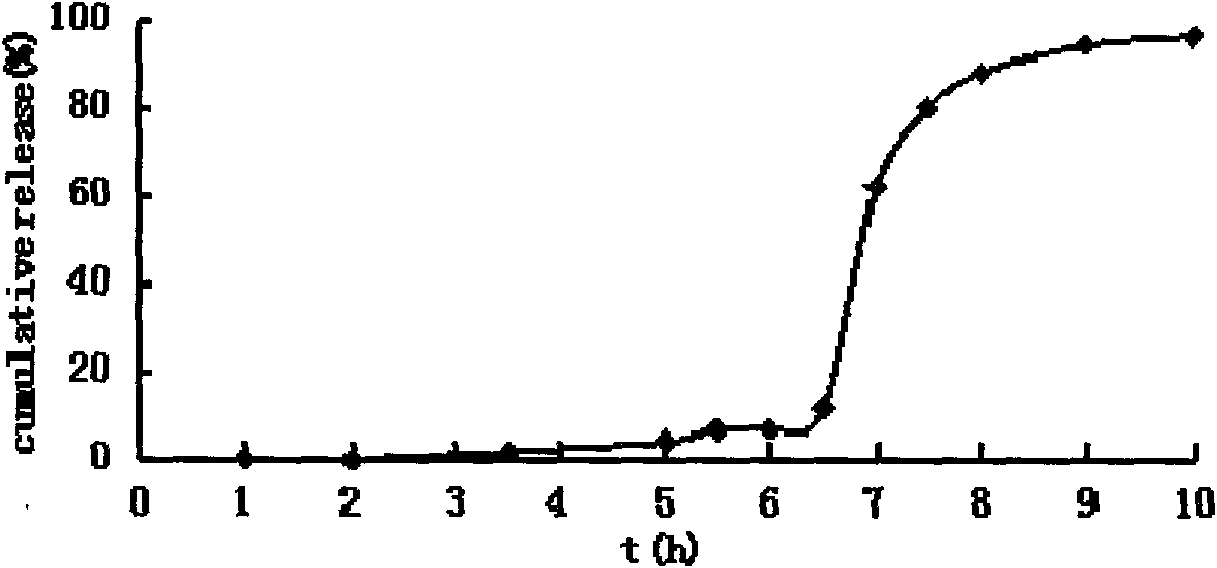

[0068] Take indomethacin as a model drug, mix indomethacin:sodium chloride=1:2, indomethacin is 25mg, fill it into the capsule in the form of powder, add an enzymatic gel plug, and then put it in the capsule. Add a solub...

Embodiment 3

[0074] Insoluble microporous membrane vesicle composition:

[0075]

[0076] Preparation process: first dissolve cellulose acetate in acetone: anhydrous ethanol (4: 1) mixed solution, add glycerin as a plasticizer and PVP-K30 as a porogen, the preparation process is the same as Example 1, drying, and shelling , cutting and finishing to obtain insoluble microporous membrane capsules.

[0077] The composition of enzymolysis rubber stopper:

[0078] Pectin 25g

[0079] Magnesium stearate amount

[0080] Preparing Pectin Stoppers 250 Tablets

[0081] Preparation process: Mix pectin and magnesium stearate evenly, add them to a tablet press to press, and prepare a pectin sheet with a diameter of 5 mm, a hardness of 5.5 kg and a thickness of 0.9 mm, to obtain an enzymatic rubber plug.

[0082] Take verapamil hydrochloride as a model drug, mix verapamil hydrochloride:sodium chloride=1:1, verapamil hydrochloride is 60mg, fill it into the capsule in powder form, add enzymolysis p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com