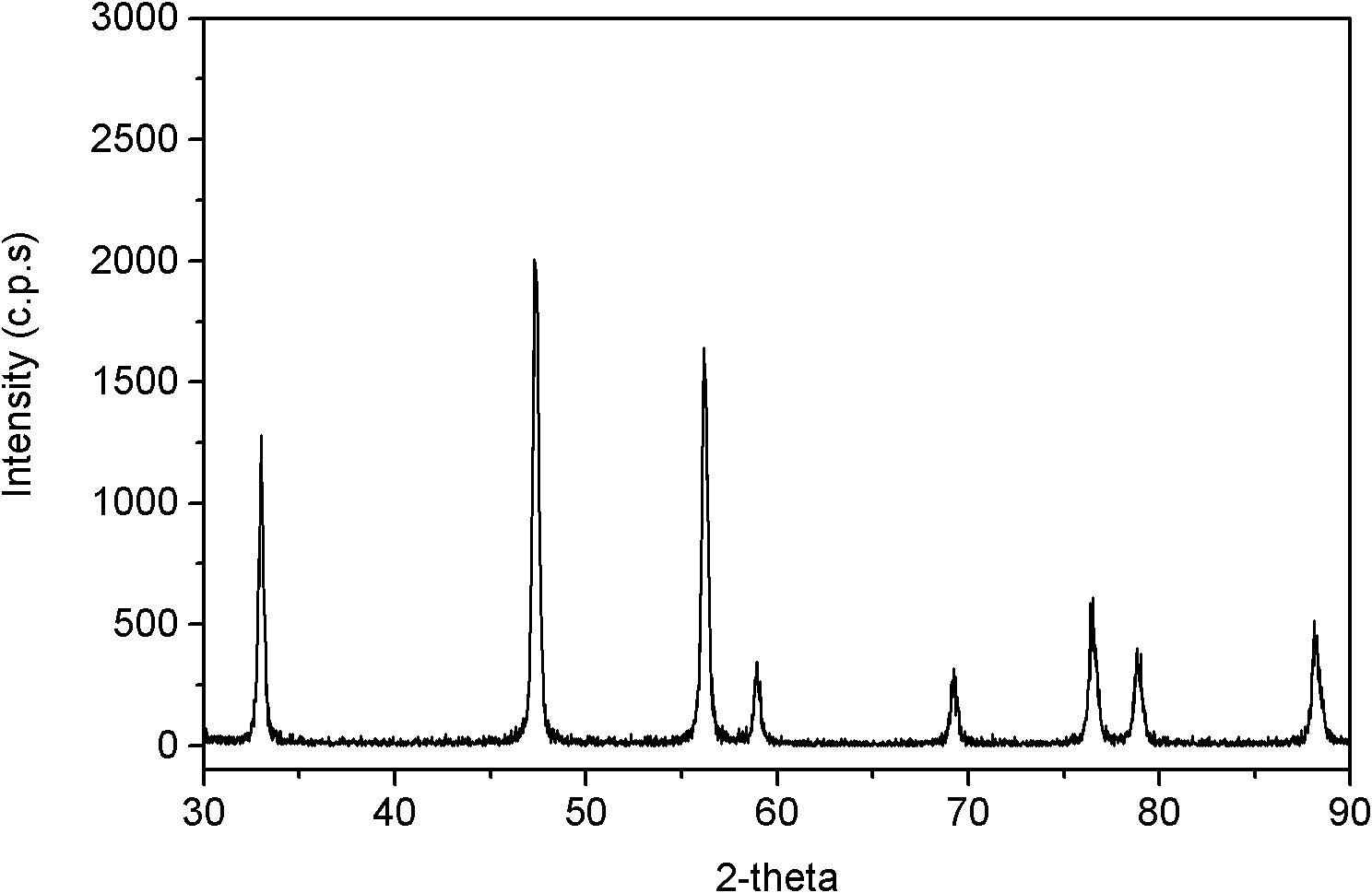

Penniform large-grain cerium-based composite oxide powder with high specific surface area and preparation method thereof

A high specific surface area, composite oxide technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve the problems of uncontrollable morphology, application limitations, etc., to avoid organic reagents and additives, simple types, The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Solution preparation: Dissolve 0.4mol cerium oxide and 0.1mol samarium oxide in dilute nitric acid solution with a concentration of 0.3mol / L respectively to obtain a mixed solution of cerium-based salt, adjust the pH to 5 with sodium hydroxide solution, and add Deionized water to make the total concentration of metal ions in the solution 0.5 mol / L. Dissolve sodium carbonate in deionized water with a concentration of 1mol / L. Heat the sodium carbonate solution to 40°C, and slowly add the cerium-based mixed solution to the sodium carbonate solution dropwise under stirring conditions, and keep the pH value of the solution greater than 10 during the dropwise addition. After the dropwise addition, the reaction solution was heated to 60-80°C, stirring was continued, and the precipitate was aged for 6 hours. The molar ratio of the metal ion of the cerium-based salt to the carbonate group is 1:2.

[0021] (2) Filter the above precipitate, wash and filter repeatedly until the ...

Embodiment 2

[0024] (1) Solution preparation: Dissolve cerium nitrate, samarium nitrate, and yttrium nitrate with a molar ratio of 0.8:0.1:0.1 in deionized water to obtain a mixed solution of cerium-based salt. The total concentration of metal ions in the solution is 2.0 mol / L. Dissolve potassium carbonate in deionized water with a concentration of 3mol / L. Heat the potassium carbonate solution to 50°C and stir. Slowly add the cerium-based mixture dropwise to the potassium carbonate solution, keeping the pH value of the solution greater than 8 during the dropping process. After the addition, the reaction solution was heated to 80° C., stirring was continued, and the precipitate was aged for 8 hours. The molar ratio of the metal ion of the cerium-based salt to the carbonate group is 1:6.

[0025] (2) Filter the above precipitate, wash and filter repeatedly until the filtrate is neutral. The precipitate was dried in a blast drying oven at 80°C for 20 hours.

[0026] (3) Then the dried precipit...

Embodiment 3

[0028] (1) Solution preparation: Dissolve cerium nitrate, strontium nitrate and lanthanum nitrate with a molar ratio of 0.6:0.1:0.3 in deionized water to obtain a mixed solution of cerium-based salt. The total concentration of metal ions in the solution is 3.0 mol / L. Dissolve potassium carbonate in deionized water with a concentration of 3mol / L. Heat the potassium carbonate solution to 50°C and stir. Slowly add the cerium-based mixture dropwise to the potassium carbonate solution, keeping the pH value of the solution greater than 12 during the dropwise addition. After the addition, the reaction solution was heated to 70° C., stirring was continued, and the precipitate was aged for 8 hours. The molar ratio of the metal ion of the cerium-based salt to the carbonate group is 1:4.

[0029] (2) Filter the above precipitate, wash and filter repeatedly until the filtrate is neutral. The precipitate was dried in a blast drying oven at 80°C for 16 hours.

[0030] (3) The dried precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com