Growth-factor-containing nanofibre porous composite material capable of repairing bone and preparation method thereof

A technology for repairing materials and growth factors, applied in the field of biomedical materials, can solve problems such as the inability to fully simulate the physiological and microenvironment of bone tissue, and achieve osteoinductive effects, satisfying bone defect repair, and promoting bone tissue regeneration and functional reconstruction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

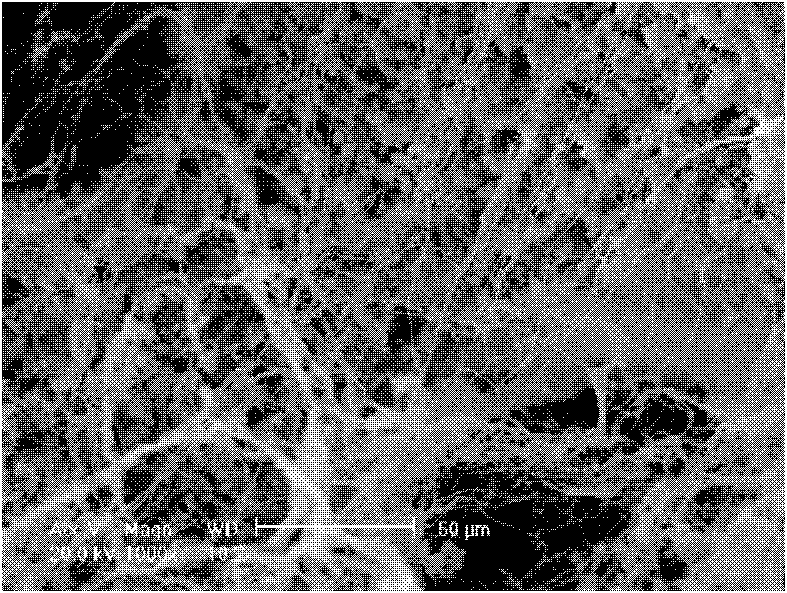

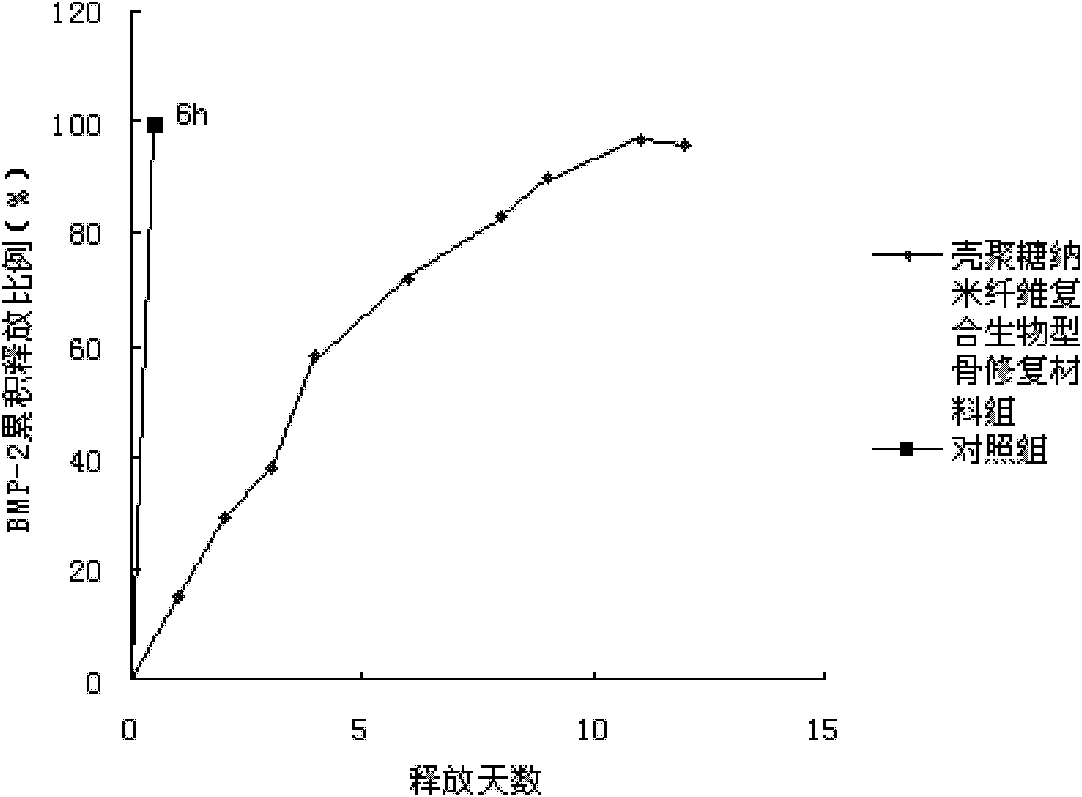

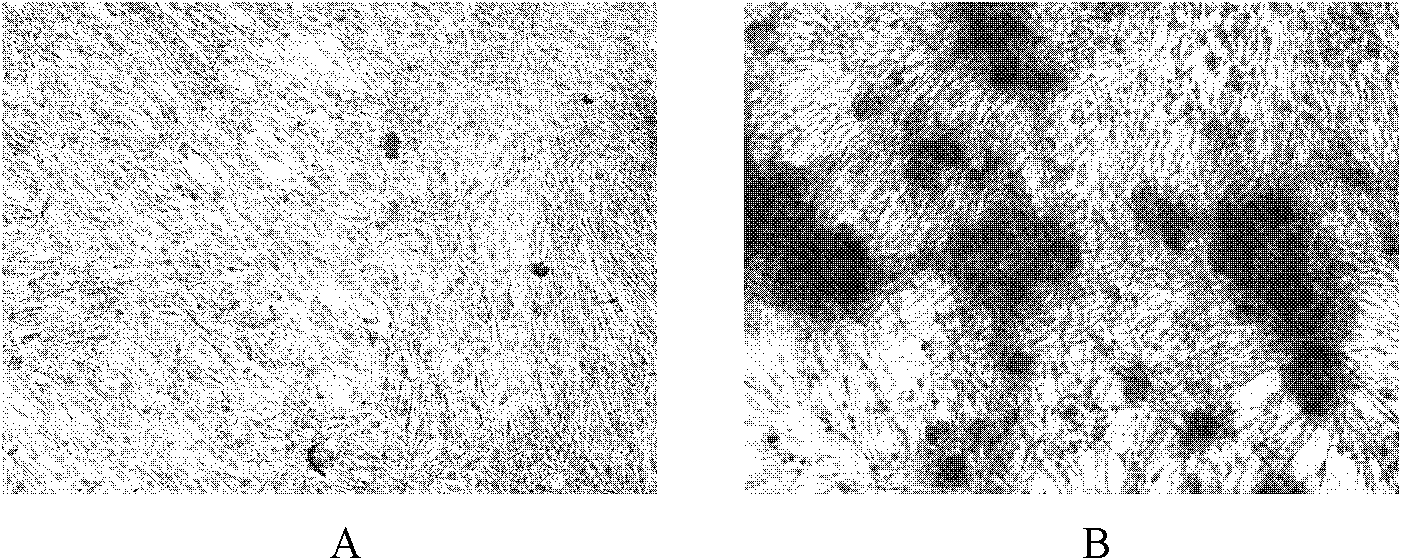

[0038] Embodiment 1: Chitosan nanofiber composite biotype porous bone repair material containing BMP-2

[0039](1) Take by weighing 1.0g chitosan (deacetylation degree 75%, relative molecular mass 200000) and be dissolved in the acetic acid solution of 0.05% (v / v), be made into the solution that concentration is 0.01 (g / mL), then in Under stirring, add BMP-2 according to the mass ratio of BMP-2 and chitosan in the ratio of 0.1:1, and mix evenly;

[0040] (2) Weigh 0.5 g of biological porous bone repair material and immerse it in the solution prepared in step (1) under negative pressure, keep it for 1 hour, and take it out;

[0041] (3) freezing the porous bone repair material treated in step (2) at -80°C, and then freeze-drying for 24 hours;

[0042] (4) Immerse the porous bone repair material treated in step (3) in ethanol aqueous solution containing 0.1mol / L sodium hydroxide as a stabilizer (the volume ratio of ethanol to water is 80:20) for stabilization, and wash with dei...

Embodiment 2

[0052] Embodiment 2: Chitosan nanofiber composite TCP porous bone repair material containing bFGF

[0053] (1) Take by weighing 1.0g chitosan (deacetylation degree 100%, relative molecular mass 20000) is dissolved in the acetic acid solution of 0.025% (v / v), is made into the solution that concentration is 0.05 (g / mL), then in Under stirring, add bFGF at a ratio of 0.001:1 by mass ratio of bFGF to chitosan, and mix evenly;

[0054] (2) Weigh 0.5 g of calcium-phosphorous bioceramic porous bone repair material TCP and immerse it in the solution prepared in step (1) under negative pressure, keep it for 2 hours, and take it out;

[0055] (3) freezing the porous bone repair material treated in step (2) at -80°C, and then freeze-drying for 12 hours;

[0056] (4) Immerse the porous bone repair material processed in step (3) in ethanol aqueous solution containing 0.05mol / L sodium polyphosphate as a stabilizer (volume ratio of ethanol to water is 90:10) to stabilize, deionized water A...

Embodiment 3

[0060] Example 3: Chitosan nanofiber composite biological porous bone repair material containing BMP-2 and bFGF

[0061] (1) Take by weighing 1.0g chitosan (deacetylation degree 91%, relative molecular mass 100000) and be dissolved in the acetic acid solution of 0.05% (v / v), make the solution that concentration is 0.025 (g / mL), then in Under stirring, add BMP-2 and bFGF according to the mass ratio of BMP-2, bFGF and chitosan at a ratio of 0.1:0.001:1, and mix evenly;

[0062] (2) Weigh 0.5 g of biological porous bone repair material and immerse it in the solution prepared in step (1) under negative pressure, keep it for 2 hours, and take it out;

[0063] (3) freezing the porous bone repair material treated in step (2) at -80°C, and then freeze-drying for 24 hours;

[0064] (4) Immerse the porous bone repair material treated in step (3) in ethanol aqueous solution containing 0.1mol / L sodium hydroxide as a stabilizer (the volume ratio of ethanol to water is 95:5) for stabilizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com