Functional liquid vitamin premix and preparation method thereof

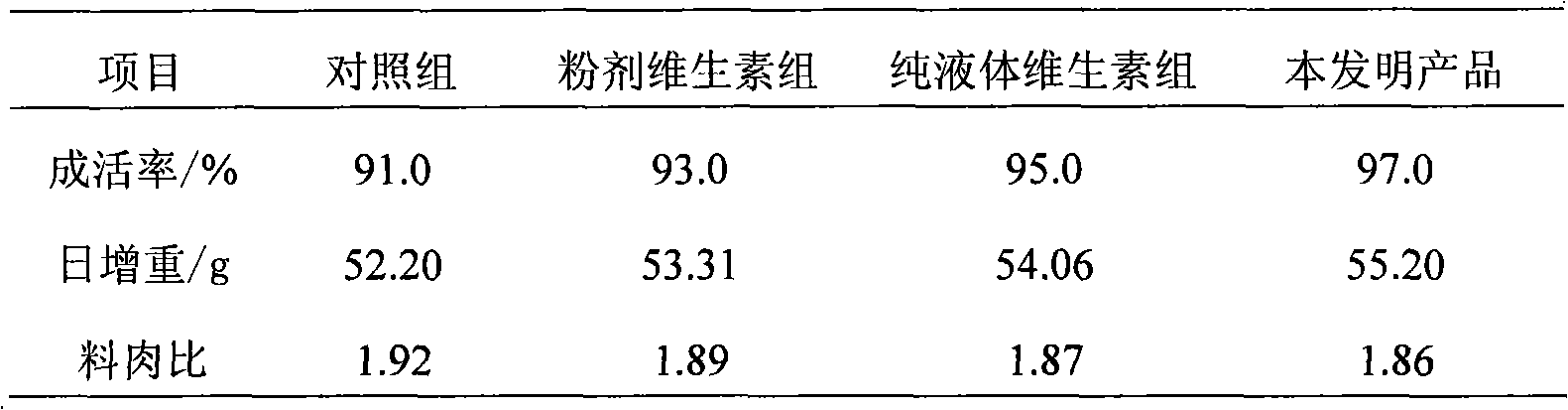

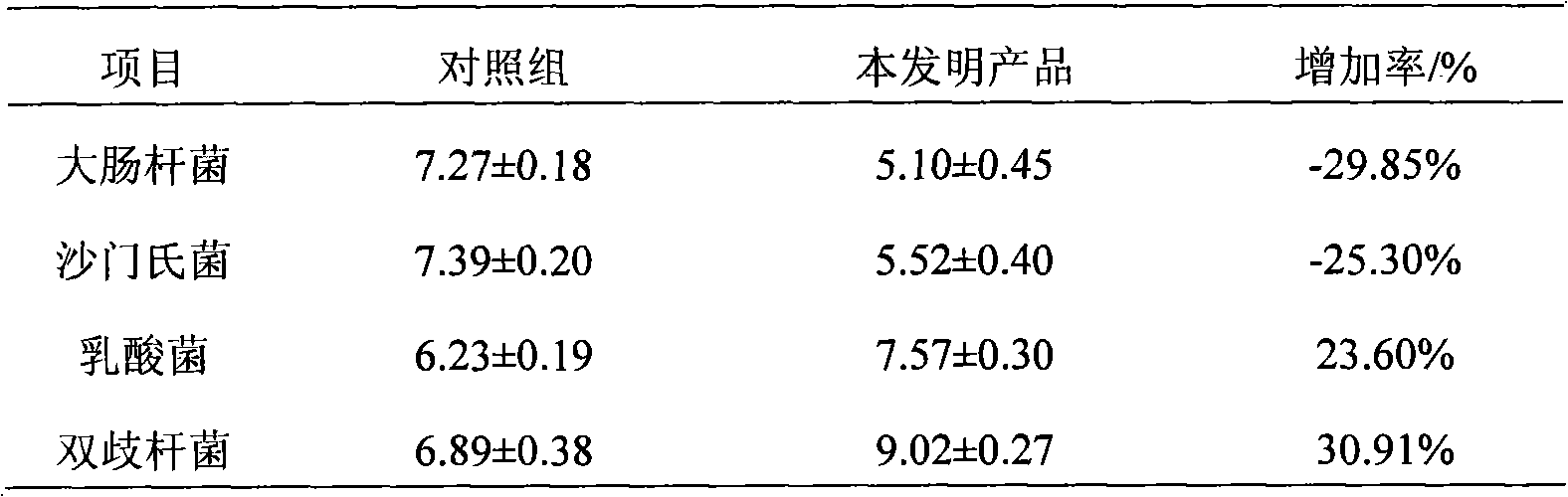

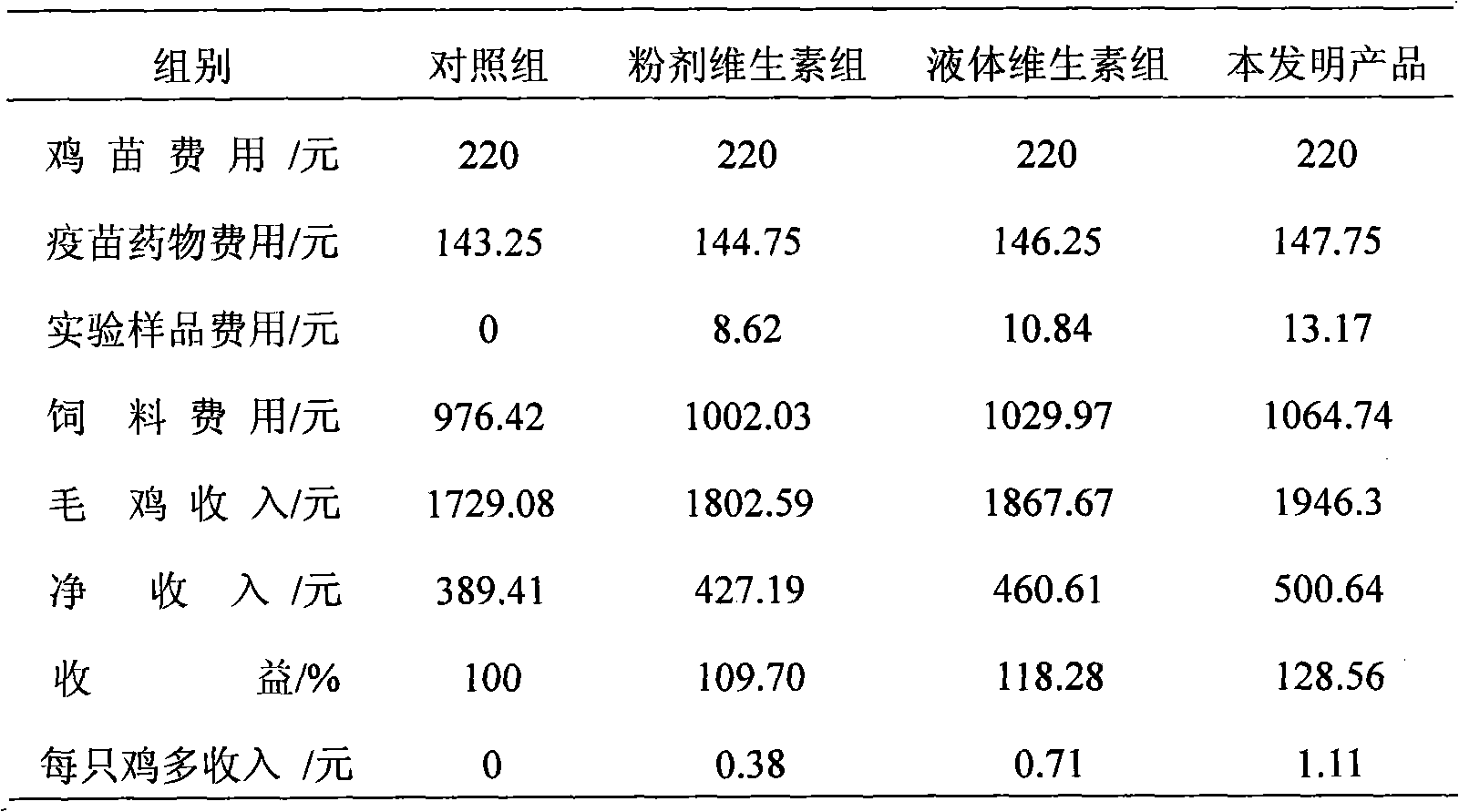

A technology of liquid vitamins and fat-soluble vitamins, applied in animal feed, animal feed, additional food elements, etc., can solve problems such as lowering market competitiveness and consumer trust, deterioration of the ecological environment, and low bioavailability, and achieve increased Effects of small intestinal villi length, regulation of intestinal flora, and promotion of metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: The premix of this embodiment is made of the following raw materials: emulsifier: Tween-80, OP-10, co-emulsifier: glycerol, stabilizer: xanthan gum, fat-soluble vitamin: vitamin A. vitamin D 3 , vitamin E and vitamin K 3 , water-soluble vitamins: Vitamin B 1 , Vitamin B 2 , Vitamin B 6 , Vitamin B 12 (1%), Niacinamide, Calcium Pantothenate, Folic Acid, Biotin (2%) and Vitamin C, Oligochitosan, Glucose Oxidase, Threonine, Tryptophan and Water. To make 1L of premix, use 150ml of Tween-80, 70ml of OP-10, 25ml of glycerol, 300mg of xanthan gum, 10500mg of vitamin A, 3000mg of vitamin D 3 , 5500mg of vitamin E, 1050mg of vitamin K 3 , 1200mg of vitamin B 1 , 2200mg of vitamin B 2 , 1800mg of vitamin B 6 , 850mg of vitamin B 12 (1%), 15500mg of niacinamide, 3500mg of calcium pantothenate, 250mg of folic acid, 550mg of biotin (2%), 10000mg of vitamin C, 20000mg of chitosan, 200ml of glucose oxidase, 2750mg of threonine , 2200mg of tryptophan.

[0047]...

Embodiment 2

[0054] Embodiment 2: The premix of this embodiment is made of the following raw materials: emulsifier: Tween-80, Span-80, co-emulsifier: propylene glycol, stabilizer: gum arabic, fat-soluble vitamins: vitamin A, Vitamin D 3 , vitamin E and vitamin K 3 , water-soluble vitamins: Vitamin B 1 , Vitamin B 2 , Vitamin B 6 , Vitamin B 12 (1%), Niacinamide, Calcium Pantothenate, Folic Acid, Biotin (2%) and Vitamin C, Oligochitosan, Glucose Oxidase, Threonine, Tryptophan and Water. To make 1L of premix, use 100ml of Tween-80, 50ml of Span-80, 20ml of propylene glycol, 400mg of gum arabic, 7500mg of vitamin A, and 2000mg of vitamin D 3 , 3000mg of vitamin E, 1000mg of vitamin K 3 , 1600mg of vitamin B 1 , 2600mg of vitamin B 2 , 1500mg of vitamin B 6 , 1100mg of vitamin B 12 (1%), 20000mg of niacinamide, 5500mg of calcium pantothenate, 320mg of folic acid, 600mg of biotin (2%), 7500mg of vitamin C, 15000mg of chitosan, 250ml of glucose oxidase, 2500mg of threonine , 2000mg of...

Embodiment 3

[0056] Embodiment 3: The premix of this embodiment is made of the following raw materials: emulsifier: Span-80, OP-10, co-emulsifier: propylene glycol and glycerol, stabilizer: soybean lecithin, fat-soluble vitamins: vitamin A, vitamin D 3 , vitamin E and vitamin K 3 , water-soluble vitamins: Vitamin B 1 , Vitamin B 2 , Vitamin B 6 , Vitamin B 12 (1%), Niacinamide, Calcium Pantothenate, Folic Acid, Biotin (2%) and Vitamin C, Oligochitosan, Glucose Oxidase, Threonine, Tryptophan and Water. To make 1L of premix, use 100ml of Span-80, 80ml of OP-10, 10ml of propylene glycol, 5ml of glycerin, 100mg of soybean lecithin, 5000mg of vitamin A, and 1000mg of vitamin D 3 , 2000mg of vitamin E, 800mg of vitamin K 3 , 800mg of vitamin B 1 , 3500mg of vitamin B 2 , 2500mg of vitamin B 6 , 1500mg of vitamin B 12 (1%), 10000mg of niacinamide, 2500mg of calcium pantothenate, 200mg of folic acid, 1000mg of biotin (2%), 5000mg of vitamin C, 30000mg of chitosan oligosaccharide, 300ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitamins | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com