Nickel oxide nano rod array material, method for preparing same and application thereof

A technology of nanorod array and nickel oxide, which is applied in the direction of chemical instruments and methods, nickel oxide/nickel hydroxide, polycrystalline material growth, etc., can solve the problem that it is not easy to realize the control of particle size and distribution, easy residual impurities on the surface, Problems such as poor crystallinity of the product, to achieve the effect of large capacitance value, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

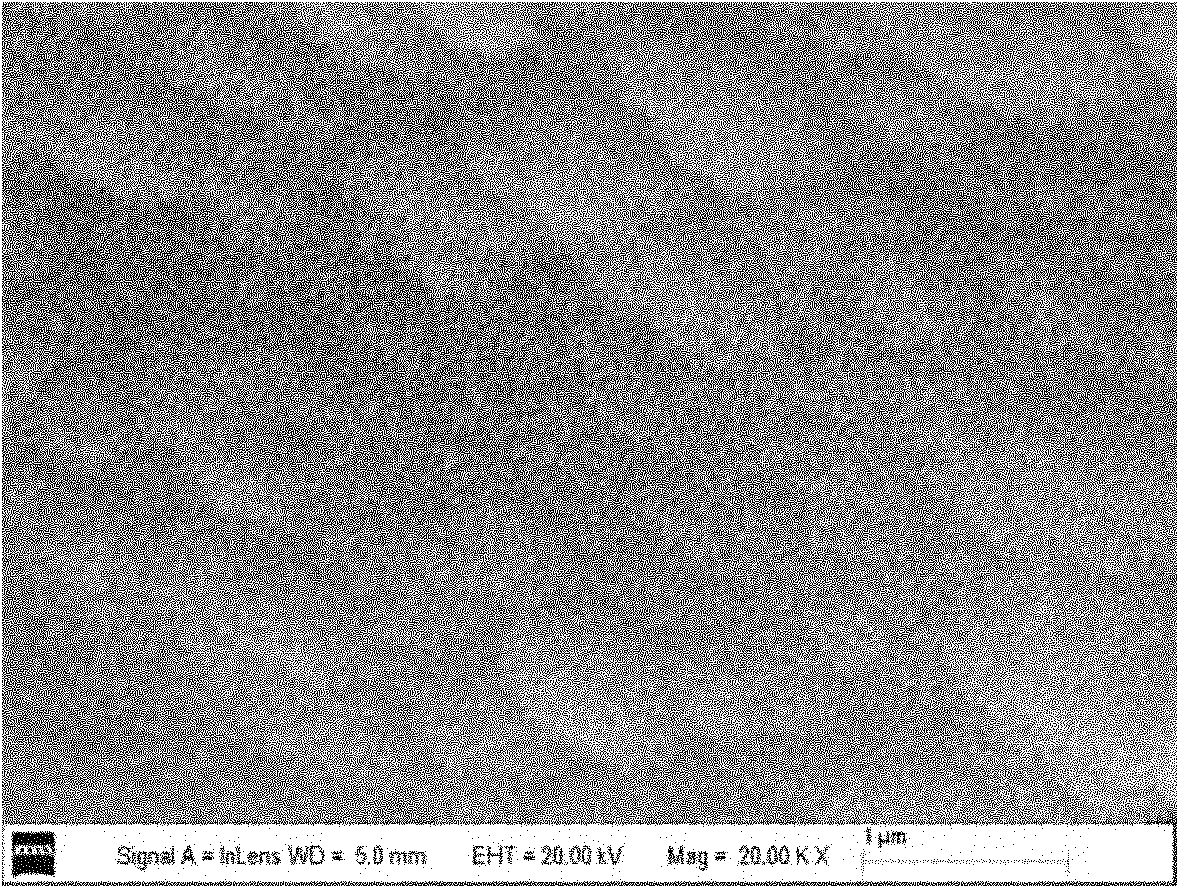

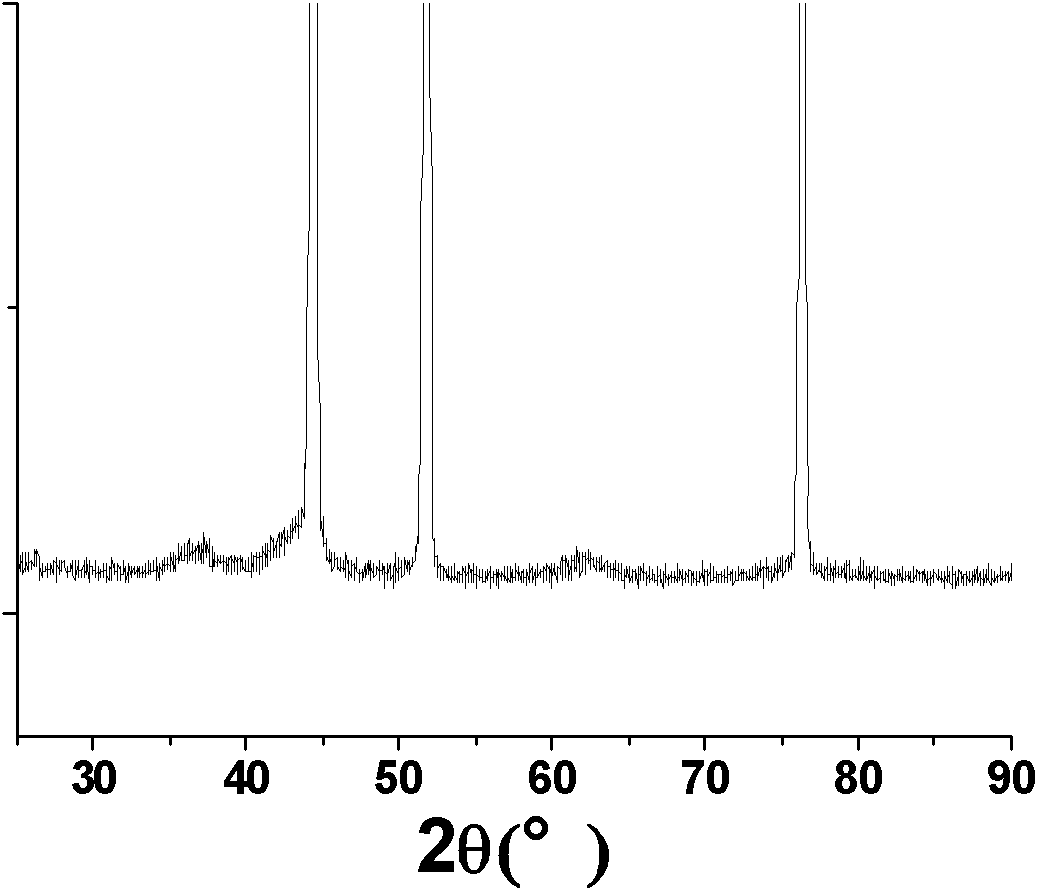

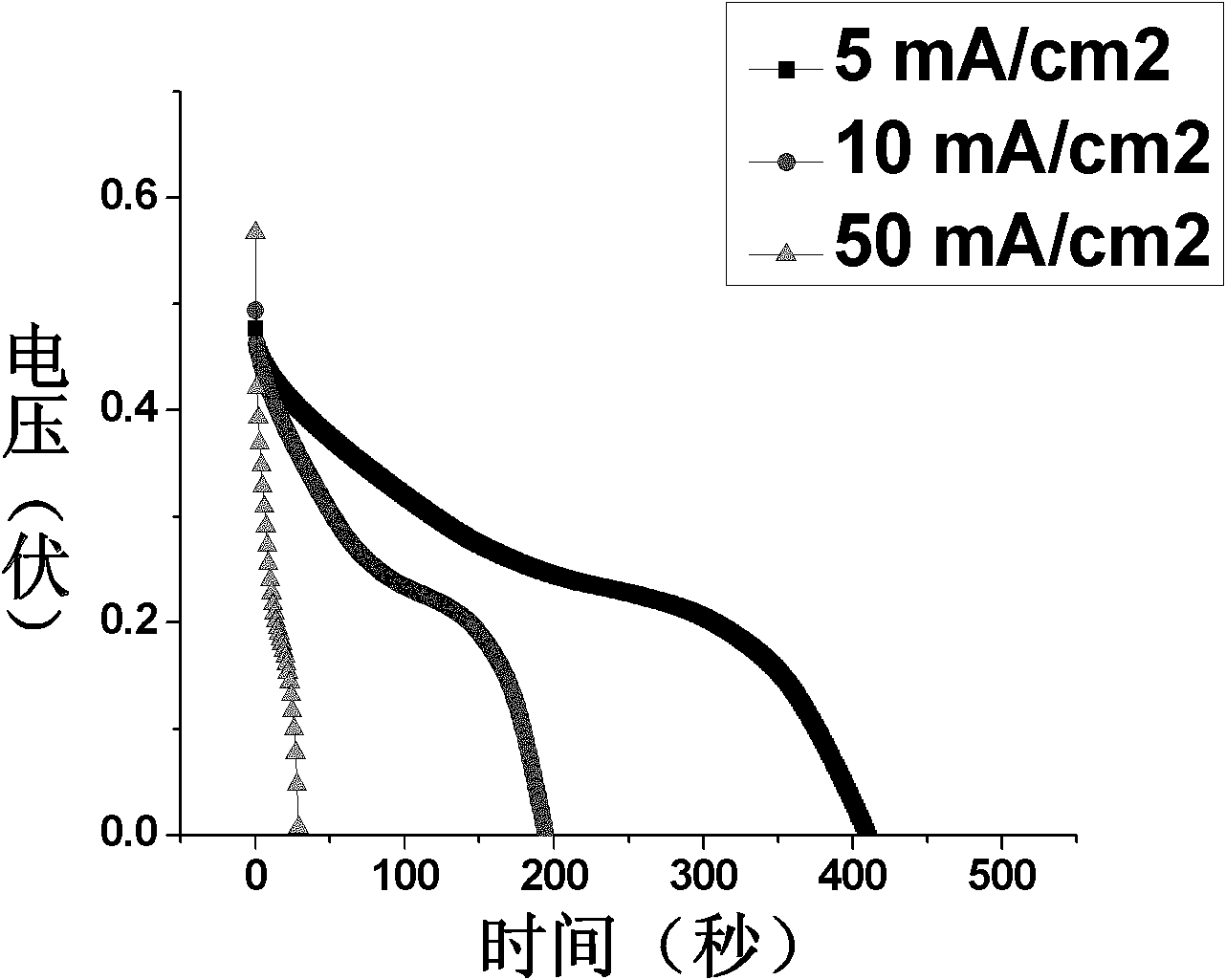

Embodiment 1

[0027] a. Take the foamed nickel sheet, put it into concentrated hydrochloric acid and ultrasonically wash it, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0028] b. the preparation of nickel nitrate hexahydrate concentration is 0.143 mol / liter and urea concentration is 0.286 mol / liter solution, fully stirred to obtain a uniform stable solution;

[0029] c. Place the foamed nickel sheet obtained in step a into a 40 ml autoclave lined with polytetrafluoroethylene, then transfer the solution in step b to the reactor and heat it at 100°C for 12 hours. After the reaction, Cool to room temperature with cooling water, and the cooling time is less than 15 minutes;

[0030] d. Take out the nickel sheet in the reaction kettle, rinse it with water and ethanol, and finally ultrasonically clean it in water and ethanol;

[0031] e. Put the product obtained in step d into an oven at 100°C and dry it for 6 hours, then put it into a tube furnace...

Embodiment 2

[0034] a. Take the foamed nickel sheet, put it into concentrated hydrochloric acid and ultrasonically wash it, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0035] B. preparation nickel chloride hexahydrate concentration is that 0.05 mol / liter and urea concentration are the solution of 0.14 mol / liter, fully stirs to obtain uniform stable solution;

[0036] c. Place the foamed nickel sheet obtained in step a into a 40 ml autoclave lined with polytetrafluoroethylene, then transfer the solution in step b to the autoclave and heat it at 70°C for 48 hours. After the reaction Cool to room temperature with cooling water, and the cooling time is less than 15 minutes;

[0037] d. Take out the nickel sheet in the reaction kettle, rinse it with water and ethanol, and finally ultrasonically clean it in water and ethanol;

[0038] e. Put the product obtained in step d into an oven at 100°C and dry it for 6 hours, then put it into a tube furnac...

Embodiment 3

[0041] a. Take the foamed nickel sheet, put it into concentrated hydrochloric acid and ultrasonically wash it, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0042] B. preparation nickel sulfate heptahydrate concentration is the solution that 0.43 mol / liter and urea concentration are 0.58 mol / liter, fully stirs to obtain uniform stable solution;

[0043] c. Place the foamed nickel sheet obtained in step a into a 40 ml autoclave lined with polytetrafluoroethylene, then transfer the solution in step b to the reactor and heat it at 140°C for 2 hours. After the reaction Cool to room temperature with cooling water, and the cooling time is less than 15 minutes;

[0044] d. Take out the nickel sheet in the reaction kettle, rinse it with water and ethanol, and finally ultrasonically clean it in water and ethanol;

[0045] e. Put the product obtained in step d into an oven at 100°C and dry it for 6 hours, then put it into a tube furnace and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com