Growing method and application of semi-metallic titanium dioxide nanotube array film

A technology of nanotube array and titanium dioxide, which is applied in the field of field emission cathode materials, can solve the problems of not meeting the modulation requirements, low emission current density, and affecting normal work, etc., and achieves good field emission stability, excellent field emission performance, and is convenient for industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

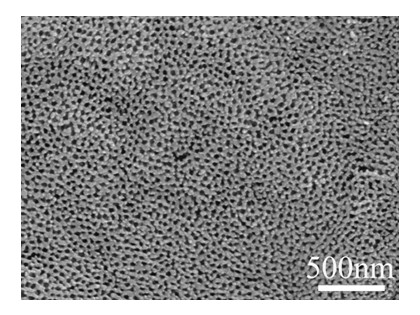

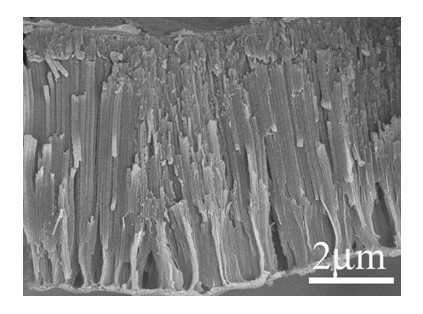

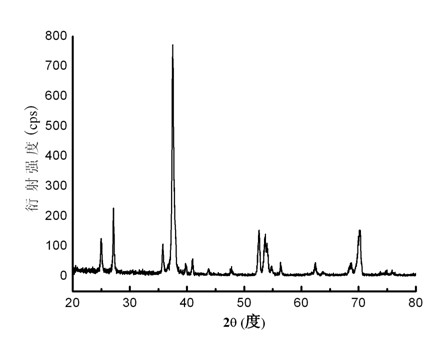

[0037]Clean industrially pure titanium sheets (purity 99.9%) in acetone, absolute ethanol and deionized water in sequence; take concentrated hydrofluoric acid with a concentration of ≥40% and hydrofluoric acid with a concentration of 36% at a volume ratio of 1:4. Concentrated hydrochloric acid is mixed to form a polishing solution, and the cleaned pure titanium sheet is put into the polishing solution for chemical polishing for 180s; a constant voltage direct current anodic oxidation method is used to grow a titanium dioxide nanotube array film on the polished pure titanium sheet: graphite is used as the cathode , the pure titanium sheet is an anode, put it into an analytically pure ethylene glycol solution containing 0.2wt.% ammonium fluoride and 0.03wt.% hydrofluoric acid at room temperature to oxidize the pure titanium sheet, the gap between the cathode and the anode The distance was 3 cm, the oxidation voltage was 40 V, and the oxidation time was 60 min. During the oxidatio...

Embodiment 2

[0040] Clean industrially pure titanium sheets (purity 99.9%) in acetone, absolute ethanol and deionized water in sequence; according to the volume ratio of 1:6, take concentrated hydrofluoric acid with a concentration of ≥40% and a concentration of 38% respectively. Concentrated hydrochloric acid, mixed into a polishing solution; put the cleaned pure titanium sheet into the polishing solution and chemically polish it for 120s; use the constant voltage direct current anodic oxidation method to grow titanium dioxide nanotube array film on the polished titanium sheet: use graphite as the cathode , the titanium sheet is used as the anode, and the titanium sheet is oxidized in an analytically pure ethylene glycol solution containing 0.3wt.% ammonium fluoride and 0.05wt.% hydrofluoric acid at room temperature, and the distance between the cathode and the anode is 2cm , the oxidation voltage is 45V, and the oxidation time is 600min. During the oxidation process, stir with a magnetic ...

Embodiment 3

[0043] Clean industrially pure titanium sheets (purity 99.9%) in acetone, absolute ethanol and deionized water in sequence; take concentrated hydrofluoric acid with a concentration of ≥40% and a concentration of 36% respectively at a volume ratio of 1:8. Concentrated hydrochloric acid, mixed into a polishing solution; put the cleaned titanium sheet into the polishing solution for chemical polishing for 10s; use constant voltage direct current anodic oxidation method to grow titanium dioxide nanotube array film on the polished titanium sheet: use graphite as the cathode, The titanium sheet is an anode, and at room temperature, it is placed in an analytically pure ethylene glycol solution containing 0.25wt.% ammonium fluoride and 0.02wt.% hydrofluoric acid to oxidize the titanium sheet. The distance between the cathode and the anode is 5cm. The oxidation voltage is 60V, and the oxidation time is 120min. During the oxidation process, stir with a magnetic stirrer to ensure that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com