White solder mask composition for spraying

A technology of solder resist and composition, which is applied in the direction of coating non-metallic protective layer, photosensitive material used in optomechanical equipment, secondary treatment of printed circuit, etc., which can solve the problem of heavy environmental load, yellowing, and white solder resist composition Problems such as unsatisfactory complexes, to achieve the effects of improving production efficiency, inhibiting yellowing, and improving edge coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15、 comparative example 1~3

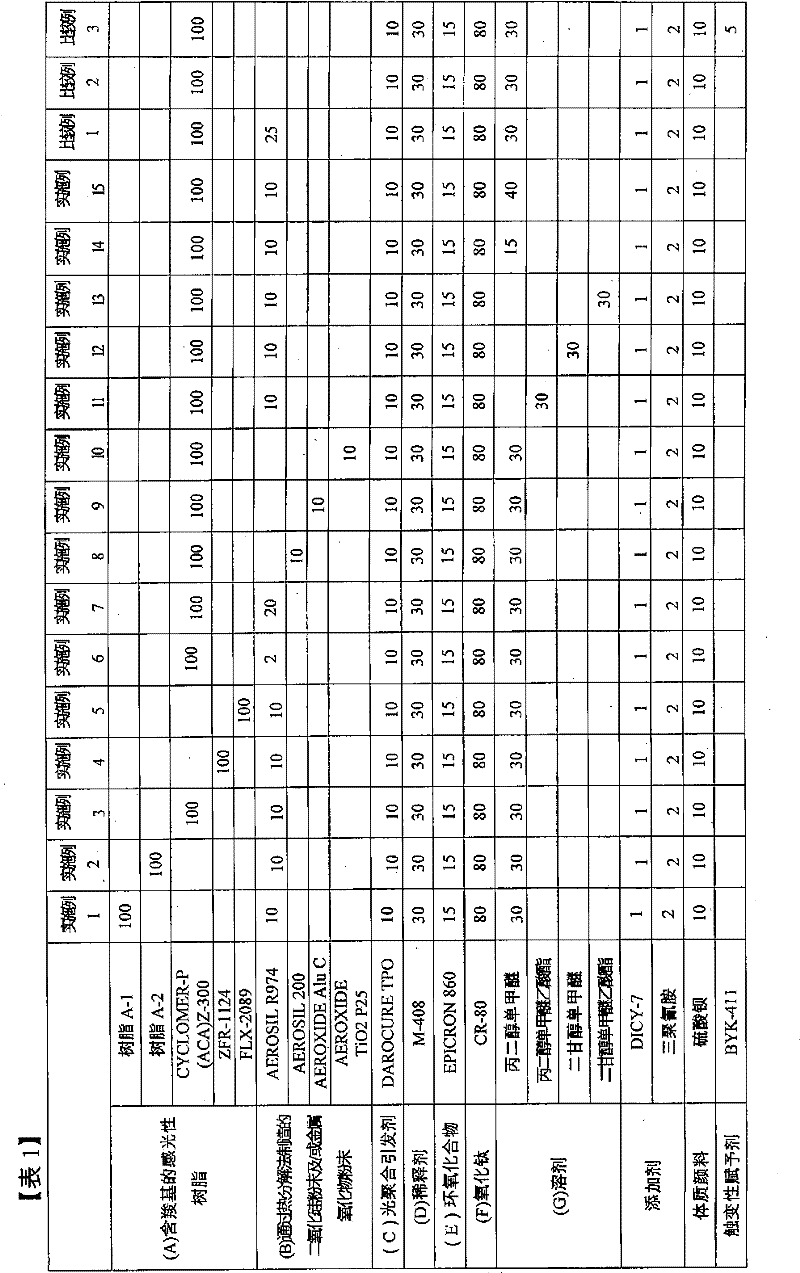

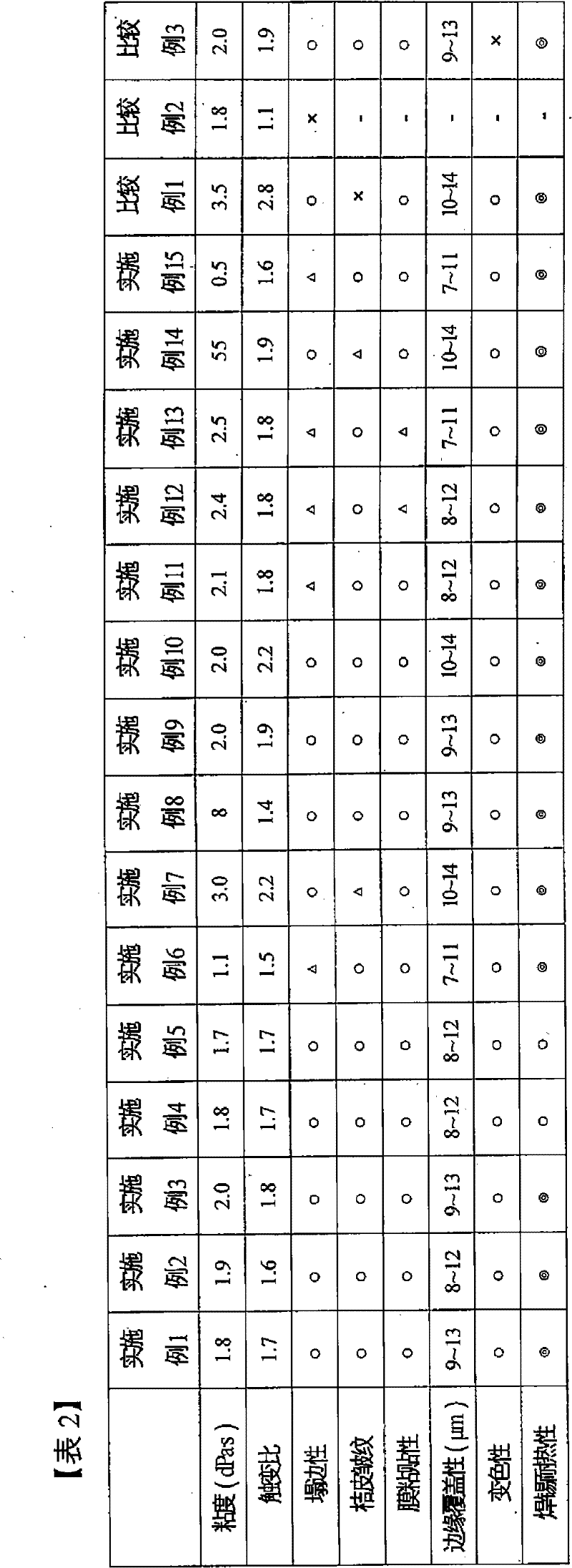

[0073] Mix the components shown in the following Table 1 according to the ratio shown in the following Table 1, use a three-roll mill, mix and disperse it at room temperature, and prepare the white paint for spraying used in Examples 1-15 and Comparative Examples 1-3. Solder resist composition. The compounded numbers in Table 1 below represent parts by mass.

[0074]

[0075] In addition, the detail of each component in Table 1 is as follows.

[0076] (A) Carboxyl-containing photosensitive resin

Synthetic example 1

[0077] Synthesis Example 1: Synthesis of Resin A-1

[0078] Add 110 parts by mass of acrylic acid (unsaturated group-containing monocarboxylic acid ), under the condition of heating to reflux, make it react according to the conventional method, in this reaction product, make 160 mass parts tetrahydrophthalic anhydride (multi-acid anhydride) react according to the conventional method, then, under heating to reflux, according to the conventional method 40 parts by mass of glycidyl methacrylate (ethylenically unsaturated monomer) was reacted to obtain a product (resin A-1).

Synthetic example 2

[0079] Synthesis Example 2: Synthesis of Resin A-2

[0080] Add 72 parts by mass of acrylic acid to a substance obtained by dissolving 210 parts by mass of cresol novolac epoxy resin (manufactured by DIC Corporation, N-680) as an epoxy resin in 120 parts by mass of diethylene glycol monoethyl ether acetate. Under the condition of heating reflux, it was made to react according to the conventional method, and among this reaction product, 76 mass parts of tetrahydrophthalic anhydrides (polybasic acid anhydride) were reacted according to the conventional method, and the product (resin A-2) was obtained.

[0081] - CYCLOMER P (ACA) Z-300: Daicel Chemical Co., Ltd. product, a carboxyl group-containing resin obtained using a resin having an acrylic copolymer structure.

[0082] · ZFR-1124: Nippon Kayaku Co., Ltd. carboxyl group-containing resin having a bisphenol F type acrylate epoxy ester structure.

[0083] · FLX-2089: Nippon Kayaku Co., Ltd. carboxyl group-containing resin havin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com