Stain for producing heat-resisting and acid-resisting cellulase with high yield and new method for fermenting cellulosic ethanol

A technology of cellulosic ethanol and cellulase, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of no major breakthrough, complexity, and many unexpected factors, and achieve low production cost , Improve production efficiency and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021]1. Through long-term screening work, obtain Aspergillus terreus M11 with high yield of heat-resistant and acid-resistant cellulase, and the strain preservation number is CCTCC M209212. The optimal reaction temperature and pH of the produced cellulase are 60-65°C and pH 2-3, and have high thermal stability. The solid fermentation condition of optimal enzyme production fermentation is: with the bran after common autoclaving steam sterilization and 0.8% yeast extract as carbon and nitrogen source, initial pH 3, add basic salt solution [(NH 1 ) 2 SO 4 3.5 g / L, KH 2 PO 4 3 g / L, MgSO 4 .7H 2 O0.5 g / L, CaCl 2 0.5 g / L] Humidity kept at about 80%, inoculate 10 6 -10 7 spores / kg cultured at 45°C. After culturing for about 90 hours, the amount of enzyme produced reaches the maximum value, and the highest filter paper enzyme activity can reach about 240U.

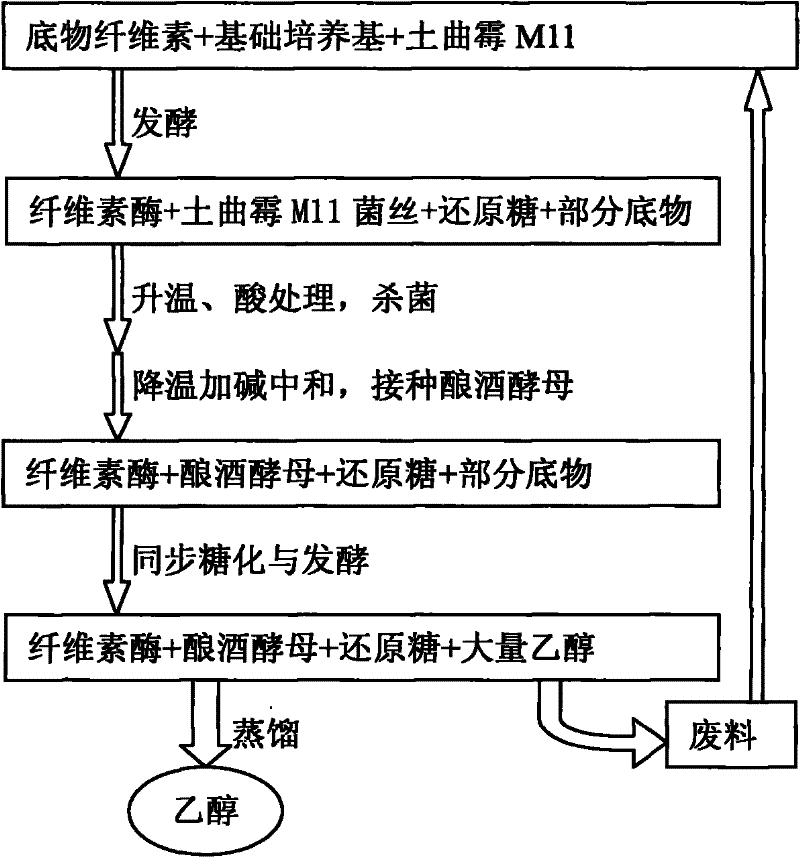

[0022] 2. Comprehensive biotechnology fermentation ethanol production technology:

[0023] (1) Solid fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com