Process method for producing yeast polysaccharide and yeast nucleotide from yeast

A technology of zymosan and a process method, which is applied in the field of yeast production of zymosan and nucleotides, can solve the problems of inability to realize large-scale industrial application, high procurement cost of hydrolyzed protease, inability to realize production cost control, etc., and achieve process production cost control. , The effect of breaking the wall is significant, and the time of enzymatic hydrolysis and alkali treatment is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

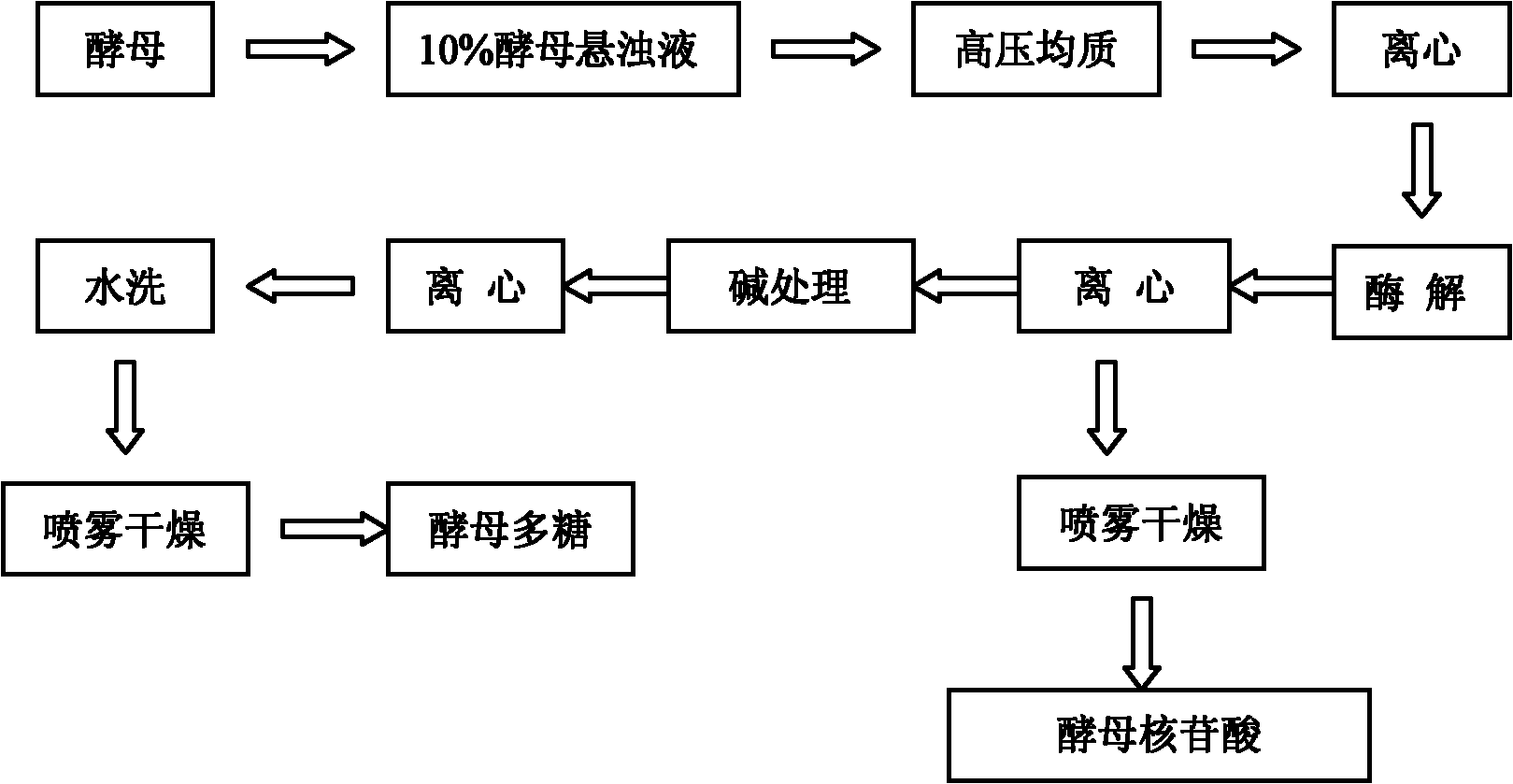

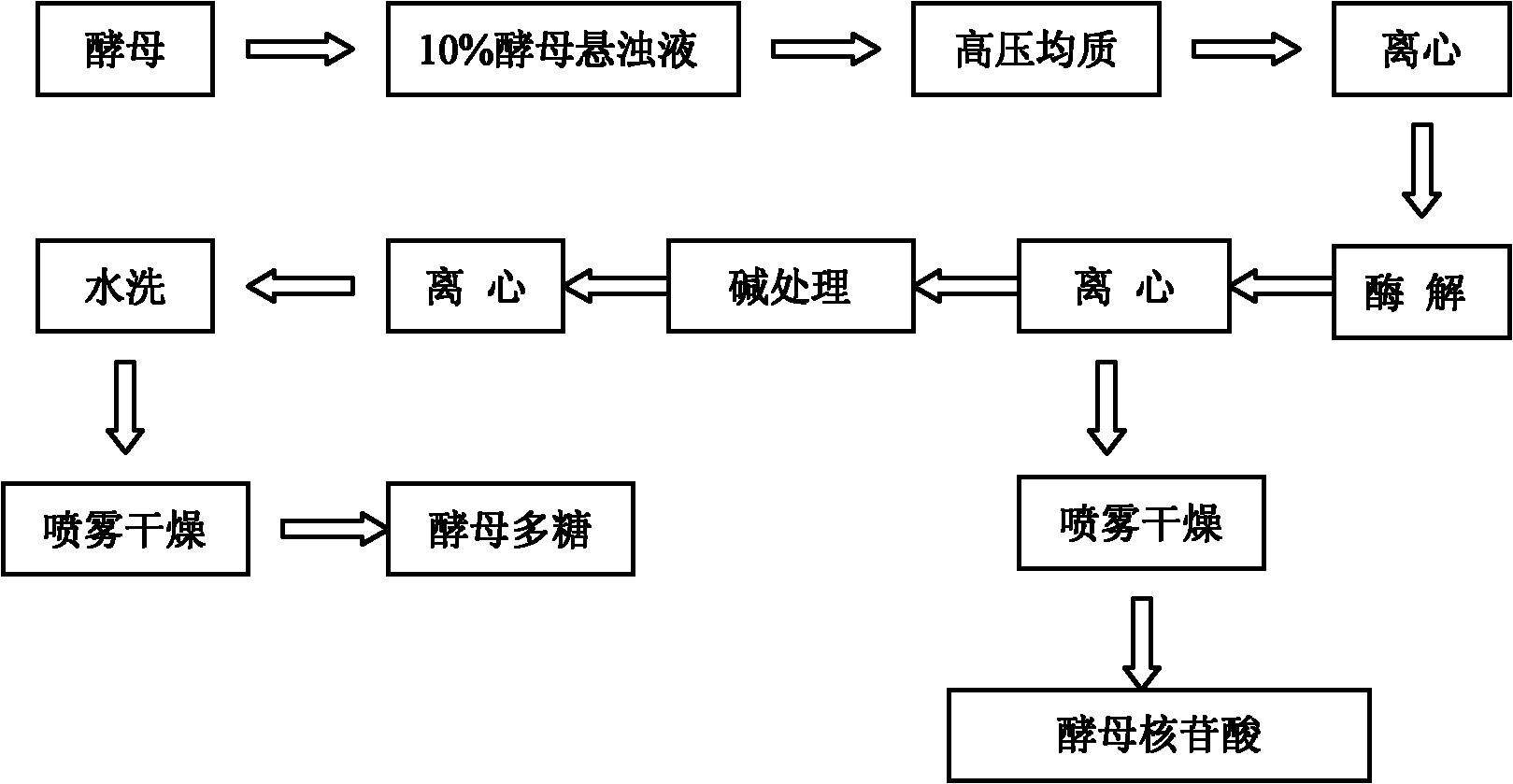

Image

Examples

Embodiment 1

[0022] Take yeast powder (waste beer yeast) and add water to the yeast suspension with a concentration of 10% (m / m), homogenize the yeast suspension at 60Mpa high pressure for 3 times, then centrifuge at 3000r / min for 5min, collect the precipitate, press 120U / g dry matter was added with papain and neutral protease (the mass ratio of the two was 1:1), the pH was 5, 55°C constant temperature enzymatic hydrolysis for 6 hours, and then centrifuged at 3000r / min for 5min to obtain the enzymatic hydrolysis precipitate and enzymatic hydrolysis supernatant, , add 3% NaOH (m / m) solution to the enzymolysis precipitate with 2ml / g dry matter, treat at 90°C for 2 hours, centrifuge at 3000r / min for 5min, collect the alkali-treated precipitate, wash it with water several times until neutral, and spray dry The zymosan was obtained (detected by the phenol sulfuric acid method, the product polysaccharide had a purity of 85.4%, and the yield was 10.5%); the enzymolysis supernatant was spray-dried ...

Embodiment 2

[0024] Take yeast powder (beer waste yeast) and add water to a yeast suspension with a concentration of 12%. Homogenize the yeast suspension at 55Mpa high pressure for 3 times, then centrifuge at 3500r / min for 5min, collect the sediment, and press 130U / g dry matter Add papain and neutral protease (the mass ratio of the two is 1:1), enzymolyze at 60°C for 7 hours, then centrifuge at 3000r / min for 5min to obtain the enzymolysis precipitate and enzymolysis supernatant, add 2ml to the enzymolysis precipitate Add 3% NaOH solution per g of dry matter, treat at 95°C for 2 hours, centrifuge at 3000r / min for 5min, collect the alkali-treated precipitate, wash it with water for several times until neutral, and spray dry to obtain zymosan (detected by the phenol-sulfuric acid method, the purity of the product polysaccharide reached 80.2%, and the yield was 8.3%); the enzymatic hydrolysis supernatant was inactivated by instant high-temperature enzyme and then spray-dried to obtain yeast nuc...

Embodiment 3

[0026] Take yeast powder (beer waste yeast) and add water to a yeast suspension with a concentration of 11%, homogenize the yeast suspension twice at 50Mpa high pressure, then centrifuge at 3000r / min for 5min, collect the sediment, and press 110U / g dry matter Add papain, enzymolysis at constant temperature at 50°C for 5h, then centrifuge at 3000r / min for 5min to obtain the enzymolysis precipitate and enzymolysis supernatant, add 3% NaOH solution to the enzymolysis precipitate at 2ml / g dry matter, and treat at 85°C for 2 hours, 3000r / min centrifuged for 5min, collected the alkali-treated precipitate, washed it with water for several times until neutral, and spray-dried to obtain zymosan (detected by the phenol-sulfuric acid method, the product polysaccharide purity reached 77.3%, and the yield was 8.0%); enzymolysis supernatant Yeast nucleotides (crude protein content 43.2%, RNA content 14.5%) were obtained by spray-drying after instantaneous high-temperature enzyme inactivation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com