Method for preparing zinc oxide nano-array on flexible substrate at low temperature

A zinc oxide nanometer and flexible substrate technology is applied in the field of preparation of nanomaterial arrays, which can solve the problems of maintaining a stable state and being unable to meet the requirements, and achieves the effects of low cost, simple and easy conditions, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

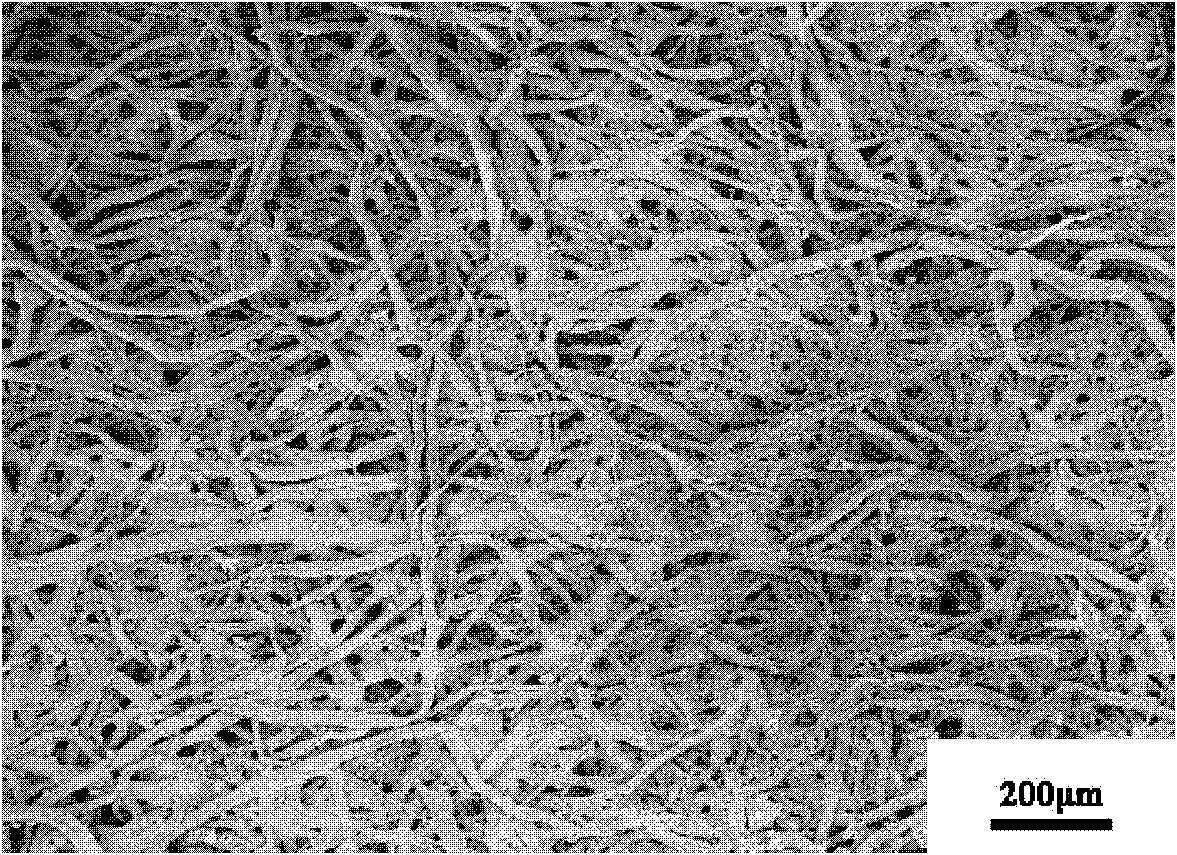

example 1

[0026] 1. Dissolve chemically pure sodium hydroxide and zinc acetate in ethanol respectively to form ethanol solution with a concentration of 1mol / L sodium hydroxide and ethanol solution with a concentration of 0.1mol / L zinc acetate, wherein the zinc acetate solution is configured The temperature is 60°C;

[0027] 2. Use ordinary filter paper as the substrate, ultrasonically clean in deionized water and ethanol for 10 minutes each, and dry at 60°C for later use;

[0028] 3. Soak the substrate cleaned in step 2 in the zinc acetate ethanol solution prepared in step 1. After fully soaking evenly, lift the liquid surface slowly and at a uniform speed, and place it in an oven at 100°C for drying;

[0029] 4. Soak the substrate treated in step 3 into the sodium hydroxide ethanol solution prepared in step 1. After fully soaking evenly, lift the liquid surface slowly and at a uniform speed, and place it in an oven at 100°C for drying;

[0030] 5. Repeat step 3 and step 4 for 10 times...

example 2

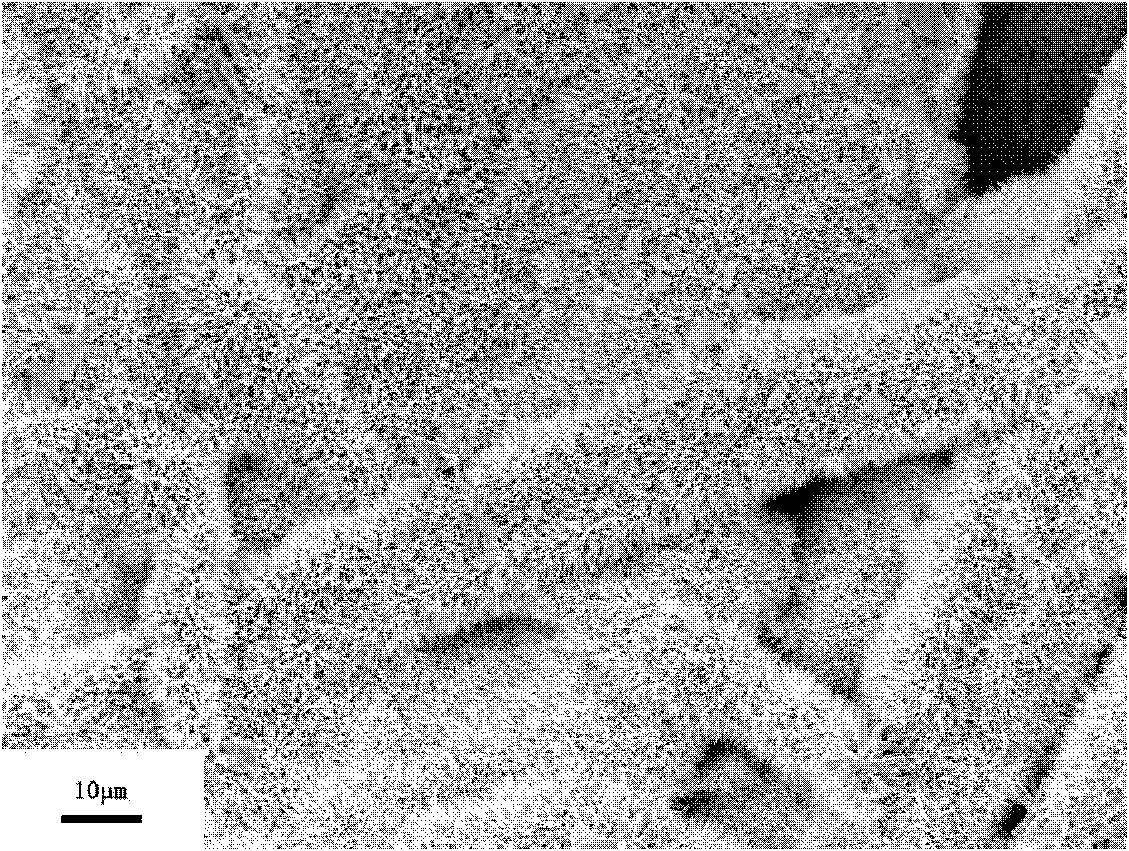

[0034] 1. Dissolve chemically pure zinc acetate and sodium hydroxide in ethanol respectively to make a concentration of 0.5mol / L sodium hydroxide ethanol solution and a concentration of 0.1mol / L zinc acetate ethanol solution, wherein the zinc acetate The ethanol solution configuration temperature is 60°C;

[0035] 2. Dissolve equimolar amounts of zinc nitrate and hexamethylenetetramine in deionized water respectively to form a mixed solution with a molar concentration of 0.05mol / L, and use it as a reaction precursor;

[0036] 3. Use ordinary filter paper as the substrate, ultrasonically wash in deionized water and ethanol for 10 minutes each, and finally dry at 60°C for later use;

[0037] 4. Soak the substrate cleaned in step 3 into the zinc acetate ethanol solution prepared in step 1. After fully soaking evenly, lift the liquid surface slowly and at a uniform speed, and dry it in an oven at 60°C;

[0038] 5. Soak the substrate treated in step 4 into the sodium hydroxide eth...

example 3

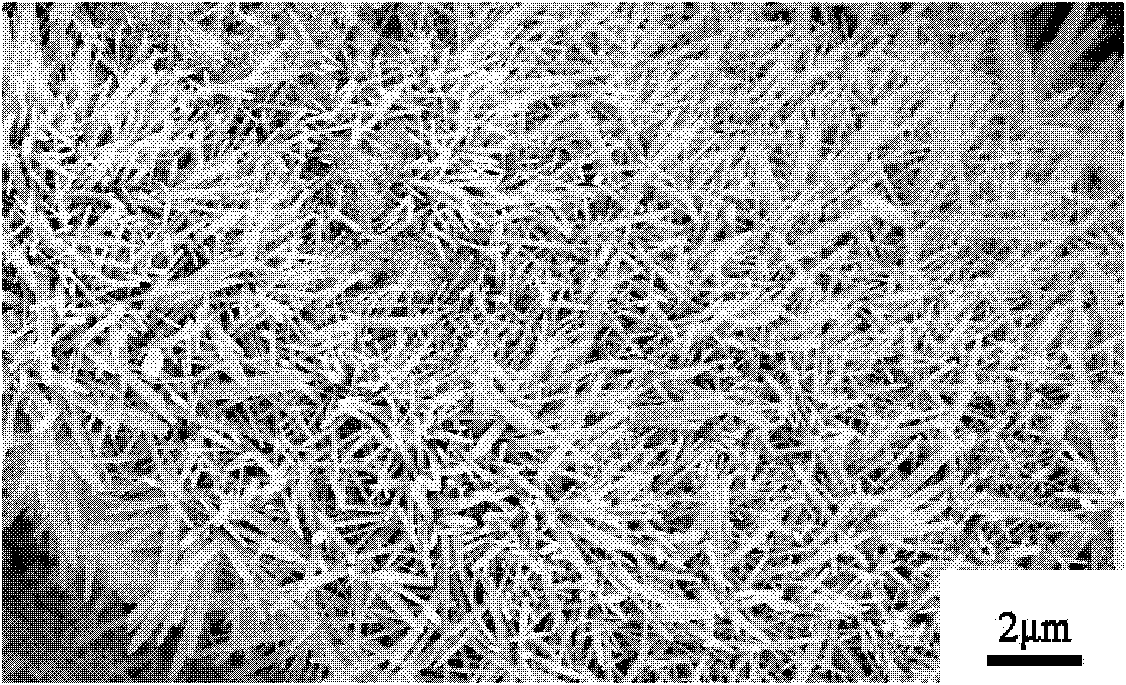

[0045] 1. Dissolve chemically pure zinc acetate and sodium hydroxide in ethanol and mix them evenly to form an ethanol solution of zinc acetate with a concentration of 0.1mol / L and an ethanol solution with a concentration of 0.5mol / L sodium hydroxide;

[0046] 2. Mix equimolar amounts of zinc nitrate and hexamethylenetetramine in deionized water respectively to form a solution with a molar concentration of 0.05mol / L. The two solutions are configured as a reaction precursor according to 1:1;

[0047] 3. Use polyimide (PI) film as the substrate, ultrasonically wash in deionized water, acetone, ethanol, and isopropanol for 10 minutes each, and dry at 60°C for later use;

[0048] 4. Evenly add a small amount of zinc acetate ethanol solution prepared in step 1 to the surface of the substrate cleaned in step 3, and dry in an oven at 60°C;

[0049] 5. Evenly add a small amount of sodium hydroxide ethanol solution prepared in step 1 to the surface of the substrate treated in step 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com