Method for preparing Ag/TiO2 nano composite material

A technology of nanocomposite materials and target materials, which is applied in the field of preparation of Ag/TiO2 nanocomposite materials, can solve the problems that the superior performance of nanocomposite materials cannot be effectively exerted, and achieve the reduction of the forbidden band width, broaden the application range, and high The effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

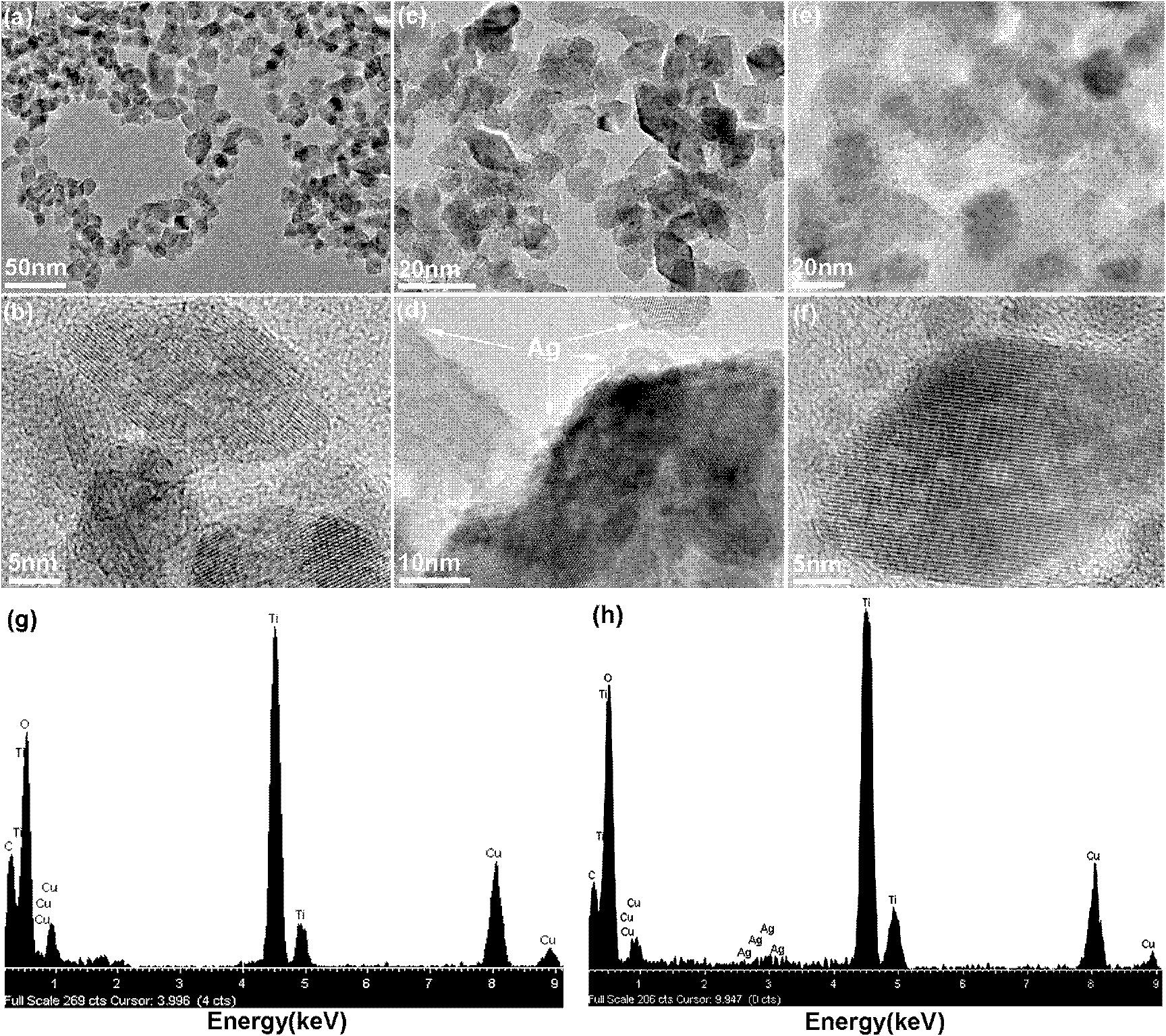

[0017] A Ag / TiO 2 The preparation method of nano composite material is characterized in that comprising the following steps:

[0018] (1) Immerse the titanium element target in deionized water, use Nd:YAG pulsed laser with a wavelength of 1064nm, energy 95mJ, and ablate the titanium element target for 15-25 minutes to obtain amorphous TiO X colloid;

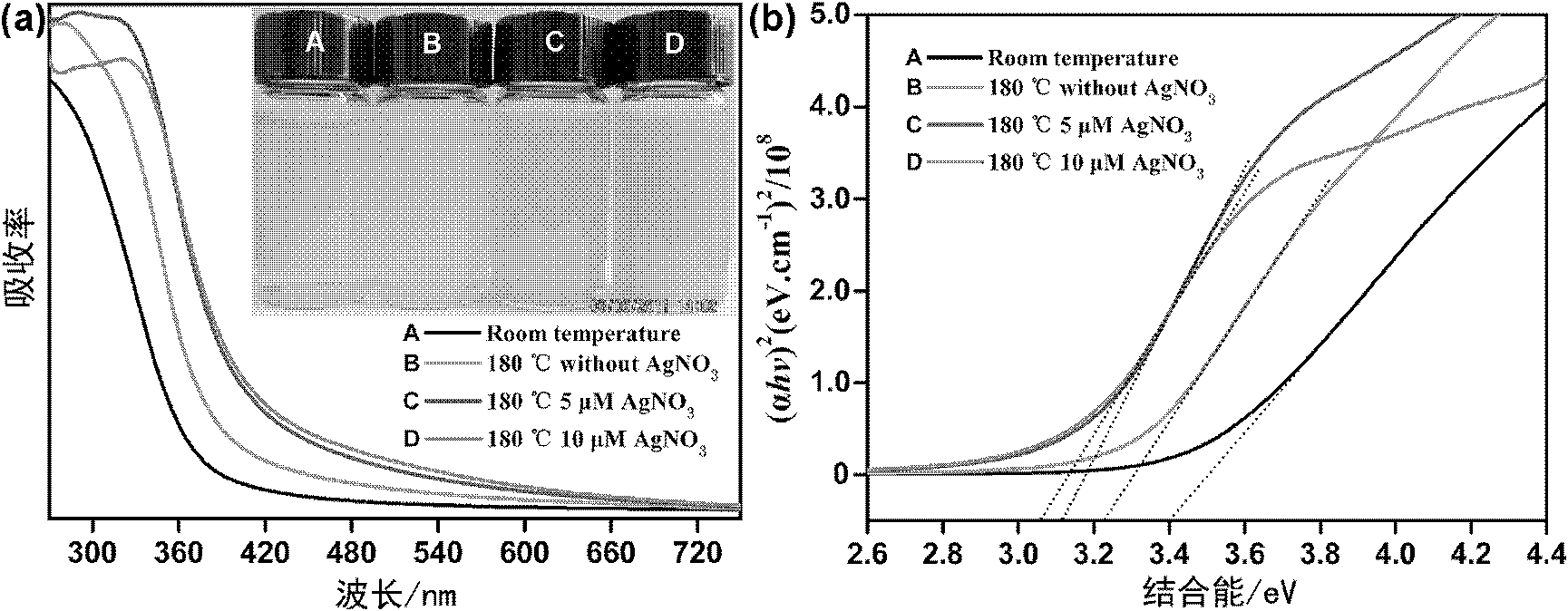

[0019] (2) Under the condition of avoiding light, to the above TiO X Add silver nitrate solution dropwise to the colloid so that the silver ion concentration of the solution is 5-15μM, and the ultrasonic dispersion is uniform for 8-12min;

[0020] (3) The above-mentioned uniformly dispersed solution is subjected to hydrothermal treatment in a high-pressure reactor for 14-18 hours, and the temperature is controlled at 170-190 ° C to obtain Ag / TiO 2 nanocomposites.

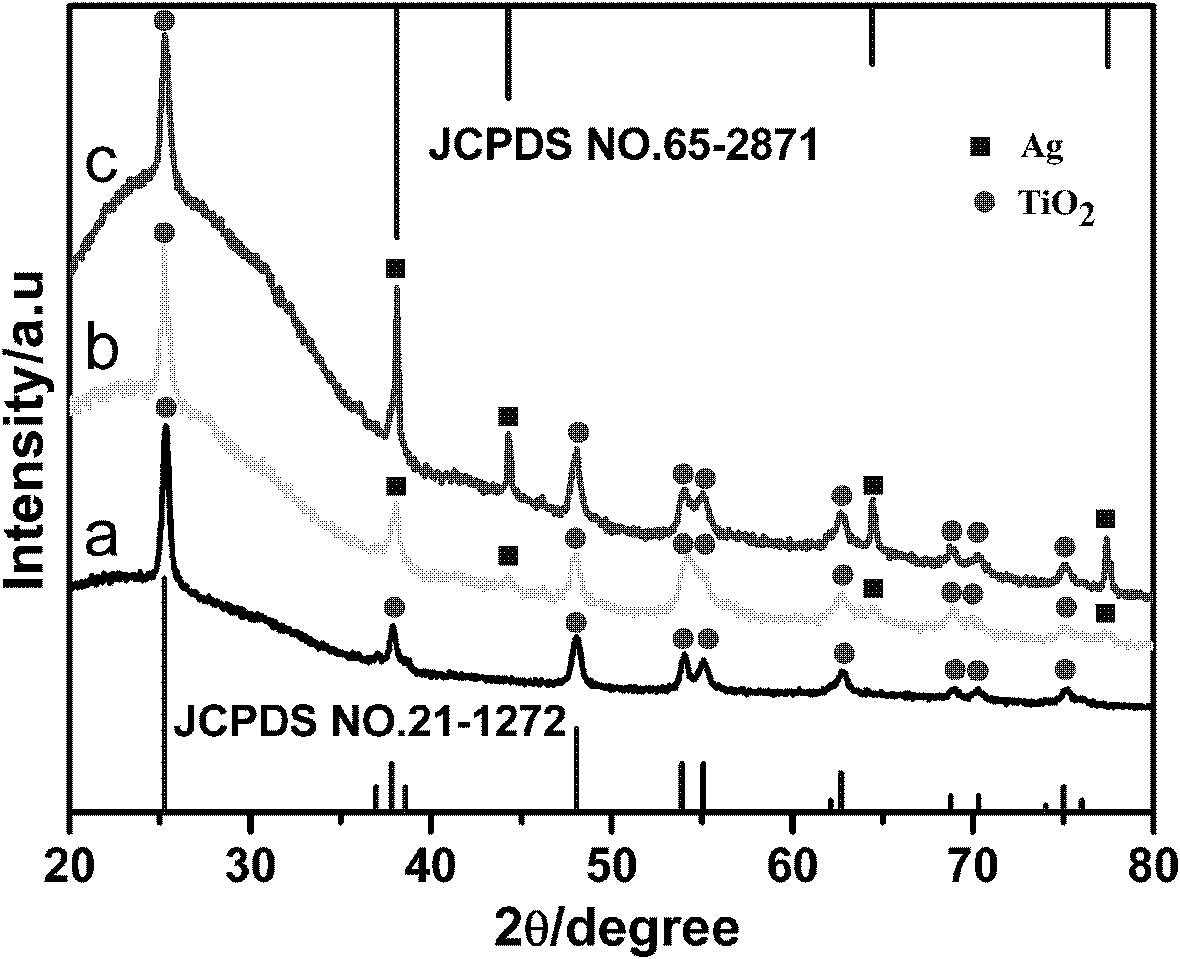

[0021] figure 1 for different TiO X The XRD results of the colloidal solution after hydrothermal treatment, a) TiO without silver ions X Colloidal solution, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com