Porcine plasma antioxidant peptide

An antioxidant peptide, pig plasma technology, applied in the field of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

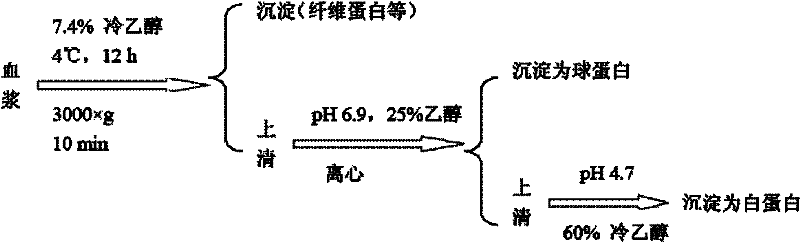

[0033] 1.1 Separation of porcine plasma albumin and globulin

[0034] On the same day, fresh pig blood from Beijing Resources Meat Group was added with potassium oxalate at a concentration of 1.0mg / mL for anticoagulation, and transported to the laboratory under refrigerated conditions, avoiding violent shaking during the process to avoid hemolysis. Centrifuge at 3000×g for 15 minutes, and the supernatant is plasma.

[0035] Utilize Heide K, Haupt H, Schwick HG.1984.Plasma protein fractionation.In:PutnamFW,editors.The Plasma Proteins.New York:Academic Press.p545-597.Recorded in the cold ethanol precipitation method separation albumin in plasma and Globulin, see the specific process route figure 1 .

[0036] 1.2 Determination of Antioxidant Peptides and Proteases Prepared by Hydrolyzing Pig Plasma

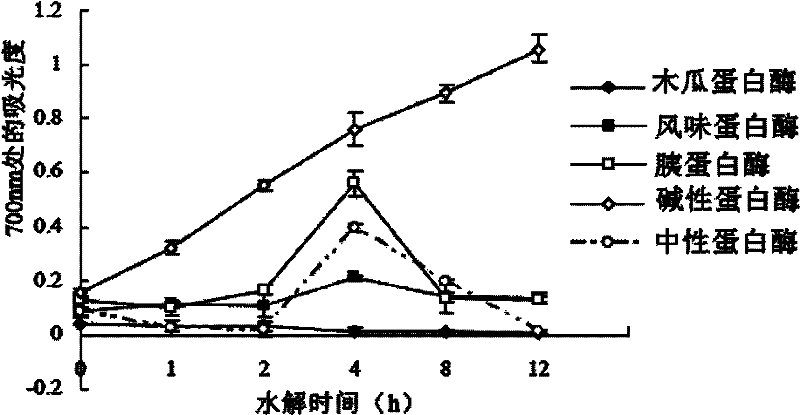

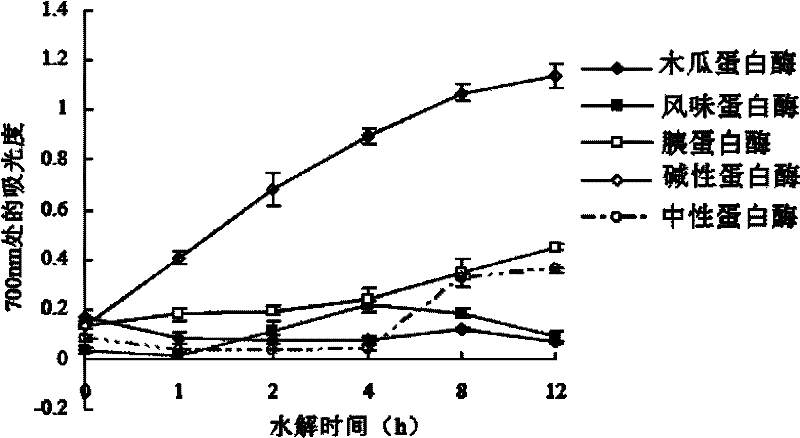

[0037] Use papain (papain), flavor protease (flavorzyme), trypsin (trypsin), alkaline protease (Alcalase) and neutral protease (neutrase) to hydrolyze porcine plasma albumin and glo...

Embodiment 2

[0050] 2.1 Restoration ability

[0051] The concentration of each peptide segment used to determine the reducing ability is 5 mg / mL, the determination method is referring to the method of Oyaizu (1986), and the results are shown in Figure 7 . Figure 7 The RP values of different molecular weight peptides of porcine plasma albumin and globulin are shown. It can be seen from the figure that the RP values of peptides of different molecular weights of albumin and globulin increase with the decrease of molecular weight. Among all the peptides, A5 had the strongest reducing ability (P<0.01). Our results indicated that low-molecular-weight peptides have a higher reducing ability, which may be due to the cleavage of natural peptide bonds during protein hydrolysis, which opens and exposes some active amino acids, thereby reacting with oxidants to play an antioxidant role. There are also different reports on this point. Some people think that the reducing ability of small molecu...

Embodiment 3

[0066] Embodiment 3 in vivo experiments

[0067] 3.1 Experimental animals

[0068] SPF grade SD (Sprague Dawley) rats, male, purchased from Weitong Lihua Experimental Animal Company (Beijing), aged three months, weighing 350-400g, in the SPF grade experimental animal room of the Institute of Genetics and Development, Chinese Academy of Sciences feed. After the rats were purchased, they were raised in the environment where they were raised for one week to allow them to adapt to the environment. See Example 1 for the preparation of A5.

[0069] 3.2 Grouping and feeding of rats

[0070] SD rats were randomly divided into 10 negative control groups, 10 positive control groups, and 10 albumin peptide A5 low-, medium-, and high-dose groups. They were raised in separate cages, with 5 rats in each cage. Rat feed composition (%): standard flour 74, skimmed milk powder 15, vegetable oil 5, crude fiber 2, mixed inorganic salt 3, mixed trace elements 0.5, mixed vitamins 0.5. Albumin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com