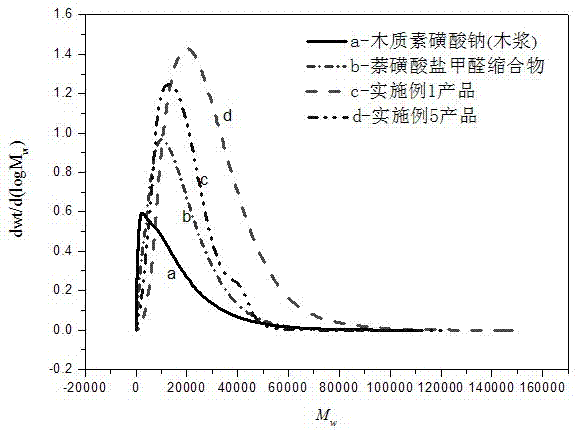

Laccase activated and modified sulfonated soda lignin amphiphilic polymer and preparation method and application thereof

A technology of amphiphilic polymer and alkali lignin, which is applied in the field of laccase-activated modified sulfonated alkali lignin amphiphilic polymer and its preparation, achieving the effects of low production cost, overcoming severe reaction conditions and mild modification conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

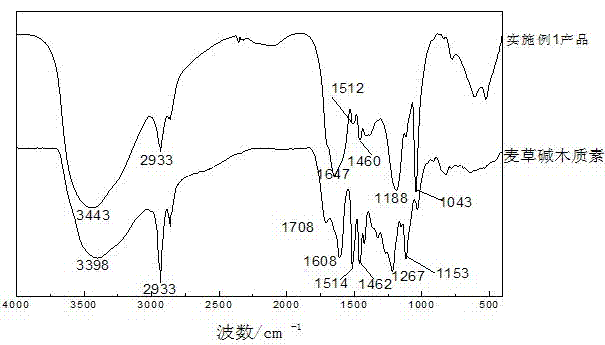

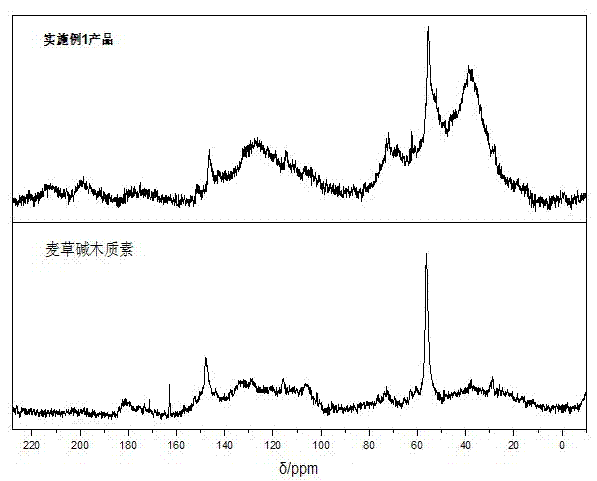

Embodiment 1

[0048] Dissolve 100g of wheatgrass alkali lignin (obtained from wheat straw pulping black liquor by acid analysis) in 150g of acetic acid-sodium acetate buffer solution with a pH of 4.5, raise the temperature to 60°C, add 200U laccase (1U= 1μmolABTS conversion / min) (the laccase derived from Coriolus versicolor , the enzyme activity is 100U / g. That is, the amount of laccase is 2g), and react for 2 hours to obtain activated alkali lignin; dissolve 10g of sodium sulfite in 90g of water, and adjust the pH to 9 with a 20% NaOH aqueous solution. When the temperature is controlled at 30°C, 5g of epichlorohydrin is added dropwise, and after 0.5 hours of reaction, the temperature is raised to 60°C, and the reaction is continued for 0.5 hours to obtain sodium hydroxysulfonate; mix it with activated alkali lignin, and adjust the pH to 8, The temperature was raised to 95° C., and reacted for 0.5 hours, then 20 g of formaldehyde solution with a mass concentration of 20% was added dropwise...

Embodiment 2

[0050] Dissolve 100g of bamboo pulp alkali lignin (obtained from bamboo pulp alkali pulping black liquor by acid analysis) in 900g of citric acid-sodium citrate buffer solution with a pH of 6.0, heat up to 40°C, add 2000U laccase ( The laccase is derived from Rhus vernicifera , the enzyme activity is 200U / g, that is, the amount of laccase is 10g), and react for 6 hours to obtain activated alkali lignin; dissolve 30g of sodium sulfanilate in 45g of water, and adjust it with 20% NaOH 0 aqueous solution When the pH is 12 and the temperature is controlled at 40°C, 20g of epichlorohydrin is added dropwise, and after 2 hours of reaction, the temperature is raised to 60°C, and the reaction is continued for 1 hour to obtain sodium hydroxysulfonate; mix it with activated alkali lignin, adjust The pH was 12, the temperature was raised to 95°C, and the reaction was carried out for 1 hour, then 80 g of acetaldehyde solution with a mass concentration of 37% was added dropwise, and the pol...

Embodiment 3

[0052] Dissolve 100g of bamboo pulp alkali lignin in 400g of succinic acid-sodium succinate buffer solution with a pH of 4.0, raise the temperature to 50°C, and add 1000U of fungal laccase (the laccase is derived from Trametes versicolor , the enzyme activity is 300U / g), reacted for 3 hours to obtain activated alkali lignin; dissolved 10g sodium sulfite and 15g sodium bisulfite in 60g water, adjusted the pH to 10 with 20% NaOH aqueous solution, and controlled the temperature At 40°C, add 15g of epichlorohydrin dropwise, react for 1 hour, heat up to 85°C, and continue the reaction for 0.75 hours to obtain sodium hydroxysulfonate; mix it with activated alkali lignin, adjust the pH to 12, and heat up to 85°C, reacted for 1 hour, then added dropwise 70 g of isobutyraldehyde aqueous solution with a mass concentration of 30%, and carried out polycondensation reaction for 3 hours to obtain a liquid sulfonated alkali lignin amphiphilic polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com