Method for preparing hydrotalcite by adopting brucite

A technology of brucite and hydrotalcite, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of long time consumption, increase the complexity of the process, and cumbersome process, so as to reduce production costs, improve utilization value, and source raw materials wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select 4.2g brucite and 1.8gAl(OH) 3 , mix it evenly with zirconia balls with a ratio of Φ10mm: Φ6mm=50:120, the mass ratio of balls to materials is 50:1, put them into a 250mL zirconia ball mill jar, and mill at a speed of 200r in a planetary ball mill / min, ball mill for 6h, add 2mL of deionized water, continue to mill at a speed of 200r / min, ball mill for 6h, take out the material and put it into a 500mL beaker, pour 200mL of 0.1mol / L Na 2 CO 3 The solution was stirred in a water bath at 80°C for 1 hour at a stirring speed of 500r / min, washed in a centrifuge at a speed of 1500r / min, and dried at 80°C to obtain hydrotalcite;

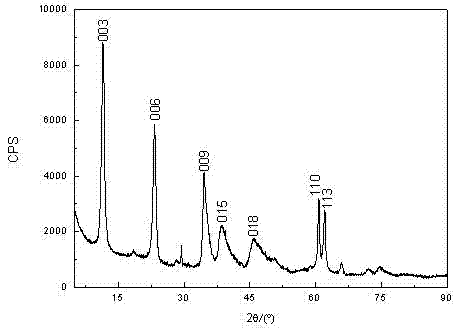

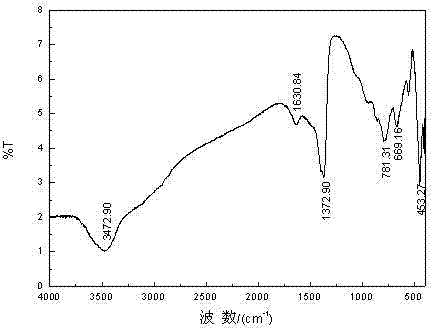

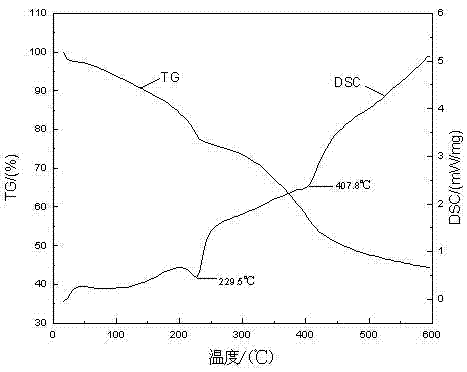

[0035] The XRD, FTIR and TG-DSC curves of the product are as follows Figure 1~3As shown, the FTIR figure shows that the product has hydroxyl and CO 3 2- , 3472.90cm -1 It is the vibration absorption peak of hydroxyl group (laminate), 1372.90cm -1 for CO 3 2- (interlayer) vibration absorption peak, 453.27.cm -1 It is the characteristic ...

Embodiment 2

[0037] Select 4.2g brucite and 1.8gAl(OH) 3 , mix it evenly with zirconia balls with a ratio of Φ10mm: Φ6mm=50:120, the mass ratio of balls to materials is 50:1, put them into a 250mL zirconia ball mill jar, and mill at a speed of 100r in a planetary ball mill / min, ball mill for 6h, add 2mL of deionized water, continue to mill at a speed of 100r / min, ball mill for 2h, take out the material and put it into a 500mL beaker, pour 200mL of 0.1mol / L Na 2 CO 3 The solution was stirred in a water bath at 80°C for 1 hour at a stirring speed of 500r / min, washed in a centrifuge at a speed of 1500r / min, and dried at 80°C to obtain hydrotalcite.

Embodiment 3

[0039] Choose 3.6g brucite and 2.4gAl(OH) 3 , mix it evenly with zirconia balls with a ratio of Φ10mm: Φ6mm=50:120, the mass ratio of balls to materials is 50:1, put them into a 250mL zirconia ball mill jar, and mill at a speed of 250r in a planetary ball mill / min, ball mill for 4h, add 3mL of deionized water, continue to mill at a speed of 250r / min, ball mill for 2h, take out the material and put it into a 500mL beaker, pour 200mL of 0.05mol / L Na 2 CO 3 The solution was stirred in a water bath at 80°C for 1 hour at a stirring speed of 500r / min, washed in a centrifuge at a speed of 1500r / min, and dried at 80°C to obtain hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com