Method for improving thermal stability of dibutyl/diisobutyl phthalate

The technology of diisobutyl phthalate and di-n-butyl phthalate is applied in the fields of fine organic synthesis, application and processing and molding of new polymer materials, and can solve the problem of increasing industrial production costs, expensive catalysts, Long production cycle and other problems, to achieve the effect of shortening the production cycle, saving the amount of alkali added, and reducing the consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

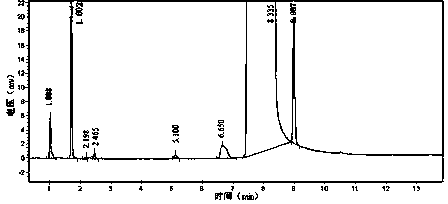

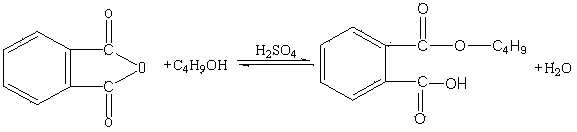

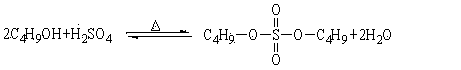

[0034] In the 15M equipped with mixing and cooling system 3 In the batching kettle, add 4.5 tons of phthalic anhydride and 6.5 tons of n-butanol, and add 34 kilograms of 98% concentrated sulfuric acid as a catalyst. After the esterification reaction for 5 hours, measure the acid value in the reaction product. When the acid value reaches 2mgKOH / g, Take 500 grams of crude ester, add 3.5 grams of powdered anhydrous solid sodium carbonate to the crude ester system under stirring conditions, maintain the reaction temperature between 130-150 ° C, heat treat for 2 hours, decompose the by-products of the esterification process, and Reduce the acid value of the system, then add 10% of the total amount of process water, stir for 1 h, achieve the purpose of fully decomposing and removing dialkyl sulfate and a small amount of phthalic acid monoester, separate the water phase, and remove the excess in vacuum To obtain the product after alcohol, heat the product at 180°C in the air for 2 ho...

Embodiment 2

[0042] In the 15M equipped with mixing and cooling system 3 In the batching kettle, add 4.5 tons of phthalic anhydride and 6.5 tons of n-butanol and add 30 kilograms of 98% concentrated sulfuric acid as a catalyst. After the esterification reaction for 5 hours, measure the acid value in the reaction product. When the acid value reaches 2mgKOH / g, the Under the condition of stirring, add 70 kg of powder anhydrous solid sodium carbonate inorganic compound to the reaction system, keep the reaction temperature between 130-150 °C, heat treatment for 2 hours, then add 10% of the total amount of process water, and stir for 1 hour to reach full For the purpose of decomposing and removing dialkyl sulfate and a small amount of phthalic acid monoester, the water phase is separated, and the excess alcohol is removed in a vacuum to obtain the product. After heating the product at 180°C in the air for 2 hours, conduct a thermal stability test. . Its main instructions are listed in Table 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com