Preparation method of organic/layered double hydroxide (LDH) complex

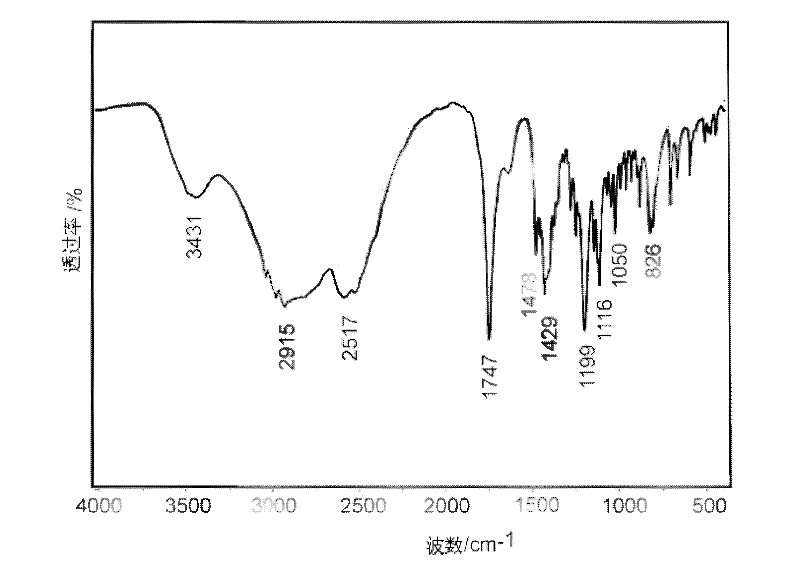

A complex and organic technology, applied in the field of organic/LDH complex and its preparation, can solve the problems of Mg/Al ratio reduction, layer composition change, and destruction of LDH precursor morphology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of this organic / LDH complex comprises the following steps:

[0054] a) Preparation of 4,7,13,16-tetracarboxymethyl-1,10-dioxo-4,7,13,16-tetraazacycloctadecane (TECA for short in the present invention):

[0055] CH 2 Cl 2 As a solvent, dissolve 1,10-dioxo-4,7,13,16-tetraza-18-crown-6 (abbreviated as L in the present invention, the structure diagram is as follows), CH 2 Cl 2 The ratio of the volume of L to the number of moles of L is 5L / mol~10L / mol. Then add anhydrous potassium carbonate to the solution for mixing, and heat to reflux for 15 minutes to 40 minutes. The mass ratio of anhydrous potassium carbonate to L is preferably 2 to 5. Add ethyl bromoacetate to the solution and reflux for 20h to 25h. The molar ratio of the volume of ethyl bromoacetate to L is 0.5L / mol to 1L / mol. The resulting solution was filtered and evaporated to obtain an oily substance (hereinafter referred to as L1 in the present invention). Hydrochloric acid solution was...

Embodiment 1

[0067] 1. Preparation of MgAl-NO 3 -LDH:

[0068] 3.20gMg(NO 3 ) 2 ·6H 2 O(0.02mmol), 2.34gAl(NO 3 ) 3 9H 2 O (0.01mmol) and 2.28g HMT (0.026mmol) were added with 50ml distilled water, reacted in the reaction kettle at 140°C for 24h, cooled at room temperature, filtered with suction, washed with water, and dried naturally to obtain MgAl-CO 3 -LDH.

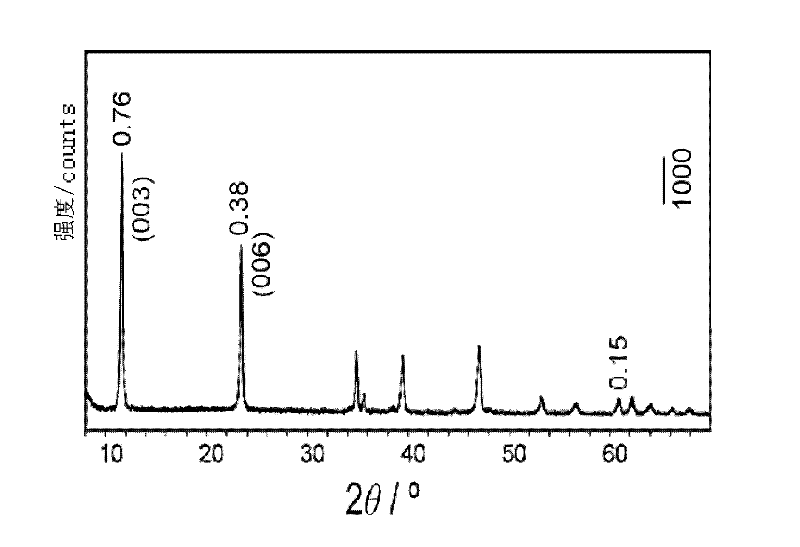

[0069] MgAl-CO 3 The XRD pattern of -LDH is shown in figure 2 . Layer spacing d basal = 0.76nm indicating the formation of CO 3 -LDH, the sharp diffraction peaks at 0.76 and 0.38nm correspond to the diffraction of its (003) and (006) planes, respectively.

[0070] Weigh 1.0g MgAl-CO 3 -LDH, add 1L containing NaNO 3 (Concentration is 1.5mol L -1 ) and HNO 3 (Concentration is 5mmol·L -1 ) in the mixed solution, sonicate for 20min, pass N 2 5min, stirred for 24h, suction filtered, exhausted and washed with water, and vacuum dried at 40°C to obtain MgAl-NO 3 -LDH.

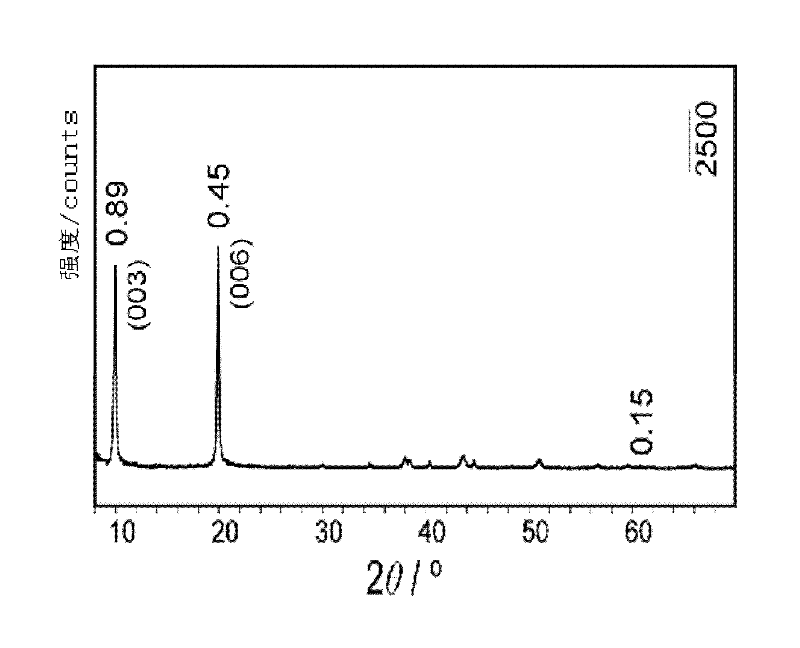

[0071] MgAl-NO 3 -XRD of LDH see image 3 . L...

Embodiment 2

[0078] Step 1 and 2 are the same as embodiment 1, add MgAl-NO in step 3 3 -The resting time of LDH after shaking is 12h, and the other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com