Self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material and preparation method thereof

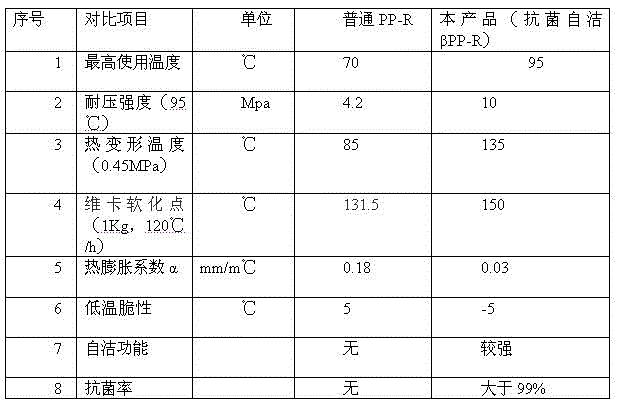

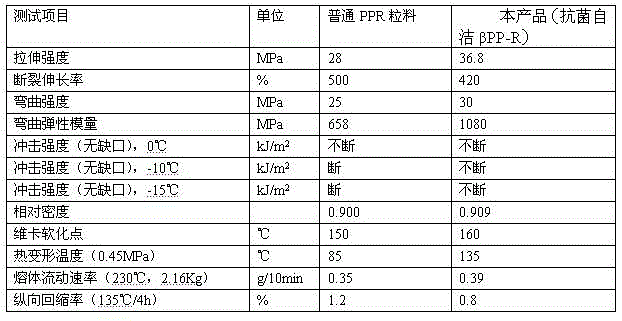

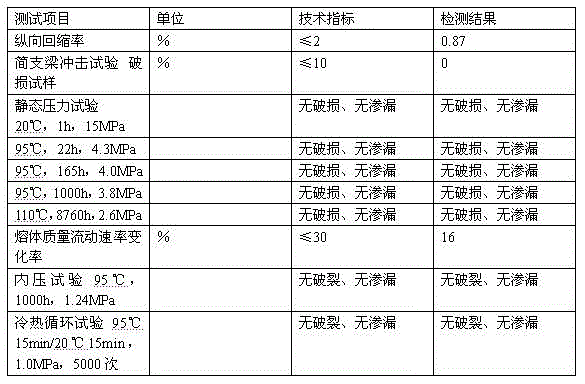

A PP-R, antibacterial and self-cleaning technology, applied to pipes, rigid pipes, mechanical equipment, etc., can solve the problems of short service life, no self-cleaning and antibacterial functions, high temperature resistance, poor pressure resistance, etc., and achieve high temperature resistance Improved performance, less brittle cracking, good impact strength at room temperature and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]A preparation method of antibacterial self-cleaning beta crystal PP-R cold and hot water pipe fittings, the preparation method comprises the following steps in sequence:

[0044] The first step: the preparation of composite β crystal nucleating agent: first take 5-10Kg lanthanum oxide, 5-10Kg pimelic acid and add it to the reactor, and react at a constant temperature of 55-65 ℃ for 8-15 minutes, and then heat up to Continue the reaction at 105-115°C for 1.5-2.5 hours, and cool to room temperature; put the material into the mixer, add 5-10Kg calcium stearate and 5-10Kg pimelic acid, at 20-30°C and the mixer rotation speed 200- Under the condition of 300 rpm, react for 3-5 minutes to generate structural formula La 3+ Ca 2+ [OOC(CH2) 5 COO] substance, then add 10-20Kg nano calcium carbonate, mix for 2-3 minutes, and obtain the structural formula of CaCO 3 / La 3+ Ca 2+ [OOC(CH2) 5 COO] complex β crystal nucleating agent.

[0045] The second step: preparation of βPP-...

Embodiment 1

[0075] Example 1: A preparation method of antibacterial self-cleaning beta crystal PP-R hot and cold water pipes, the preparation method comprises the following steps in sequence:

[0076] The first step: preparation of composite β crystal nucleating agent: first add 5Kg of lanthanum oxide and 5Kg of pimelic acid into the reactor, react at a constant temperature of 60 °C for 10 minutes, then heat up to 110 °C and continue the reaction for 2 hours, cool down to room temperature; put the material into the mixer, add 5Kg calcium stearate, 5Kg pimelic acid, the mixer speed is 200-300 rev / min, the mixing temperature is 20-30 ° C, and the mixing is 3-5 minutes, the resulting structural formula is La 3+ Ca 2+ [OOC(CH2) 5 COO] material, then add 10Kg of nano calcium carbonate, mix for 2-3 minutes, prepare a composite β crystal nucleating agent, the structural formula is CaCO 3 / La 3+ Ca 2+ [OOC(CH2) 5 COO].

[0077] The second step: preparation of βPP-R resin raw materials: f...

Embodiment 2

[0086] With embodiment 1, difference is: first get 10Kg lanthanum oxide, 10Kg pimelic acid and join in the reactor, then add 10Kg calcium stearate, 10Kg pimelic acid, then add 20Kg nano calcium carbonate; Second step: 100Kg PP-R4220, 2Kg prepared β crystal nucleating agent, 300g antioxidant 1010, 300g antioxidant DSTDP, 50g No. 10 white oil; third step: 12Kg zinc nitrate, 12Kg silver nitrate. 94Kg nanoporous titanium dioxide. The prepared 118Kg composite antibacterial agent, 6Kg polypropylene wax, 230KgβPP-R resin raw material particles; the fourth step: 100KgβPP-R resin raw material, 3Kg composite antibacterial masterbatch, 0.4Kg polypropylene wax, 0.3Kg methyl phenyl silicone oil , 1Kg superfine talcum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com