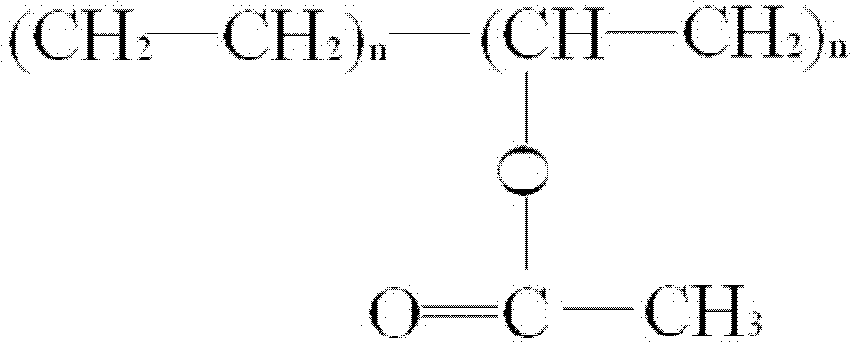

Ethylene-vinyl acetate adhesive film containing quantum dots as well as preparation method and application thereof

A vinyl acetate film, vinyl acetate technology, used in adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of reducing the photoelectric conversion efficiency of solar cells and EVA film penetration problems such as the decrease of light rate, to achieve the effect of strong operability, easy industrial production, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 10 mg of silicon quantum dots with an average size of 3 nanometers whose surface was passivated by hydrogen were prepared by plasma method. The standard deviation of the size distribution of silicon quantum dots is 10% of the mean size. Place silicon quantum dots in a mixed solution of 12 milliliters of n-heptane and dodecene (the volume ratio of the two is 5:1), heat to 80 ° C, and carry out hydrosilylation reaction under an argon atmosphere until the solution becomes It is clear, and the silicon quantum dots with carbon chains on the surface are obtained. The solution was volatilized to remove unreacted dodecene, and then the surface-modified silicon quantum dots were dissolved in 10 ml of n-heptane to obtain silicon quantum dot inks. The silicon quantum dots in the silicon quantum dot ink are excited by light with a wavelength of 325 nanometers, and the fluorescence emitted is mainly concentrated at a wavelength of 600±20 nanometers, and the fluorescence quantum eff...

Embodiment 2

[0039] 1 gram of silicon quantum dots with an average size of 3.5 nanometers whose surface is hydrogen passivated was prepared by plasma method. The standard deviation of the size distribution of silicon quantum dots is 15% of the mean size. Put the silicon quantum dots in a mixed solution of 12 milliliters of n-heptane and octadecene (the volume ratio of the two is 5:1), heat to 80 ° C, and carry out hydrosilylation reaction under an argon atmosphere until the solution becomes It is clear, and the silicon quantum dots with carbon chains on the surface are obtained. The solution was volatilized to remove unreacted octadecene, and then the surface-modified silicon quantum dots were dissolved in 12 milliliters of n-heptane to obtain silicon quantum dot inks. The silicon quantum dots in the silicon quantum dot ink are excited by light with a wavelength of 325 nanometers, and the fluorescence emitted is mainly concentrated at a wavelength of 680±20 nanometers, and the fluorescenc...

Embodiment 3

[0041]10 grams of silicon quantum dots with an average size of 4 nanometers whose surface was hydrogen passivated were prepared by plasma method. The standard deviation of the size distribution of silicon quantum dots is 15% of the mean size. Put the silicon quantum dots in a mixed solution of 12 ml of n-heptane and styrene (the volume ratio of the two is 5:1), heat to 80 ° C, and carry out hydrosilylation reaction under an argon atmosphere until the solution becomes It is clear, and silicon quantum dots with benzene rings attached to the surface are obtained. The solution was volatilized to remove unreacted styrene, and then the surface-modified silicon quantum dots were dissolved in 10 ml of n-heptane to obtain silicon quantum dot inks. The silicon quantum dots in the silicon quantum dot ink are excited by light with a wavelength of 325 nanometers, and the fluorescence emitted is mainly concentrated at a wavelength of 720±20 nanometers, and the fluorescence quantum efficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com