Method for separating and preparing five high-purity anthocyanidin monomers from grape skins

An anthocyanin and grape skin technology, which is applied in the fields of food safety and food analytical chemistry, can solve the problems of few anthocyanin standard samples, limited in-depth research, high price, etc., and achieves the effect of simple and easy separation operation and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

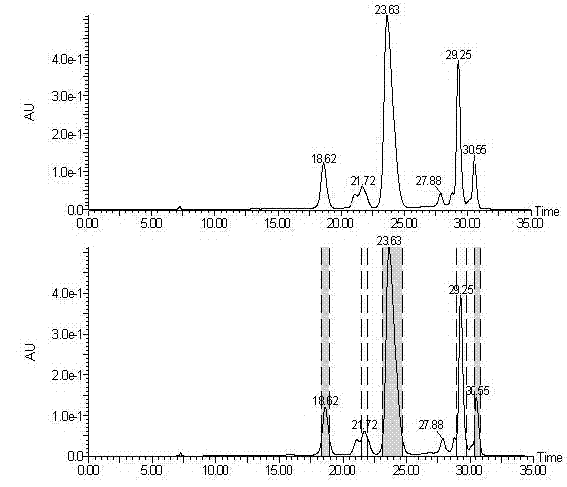

Image

Examples

Embodiment 1

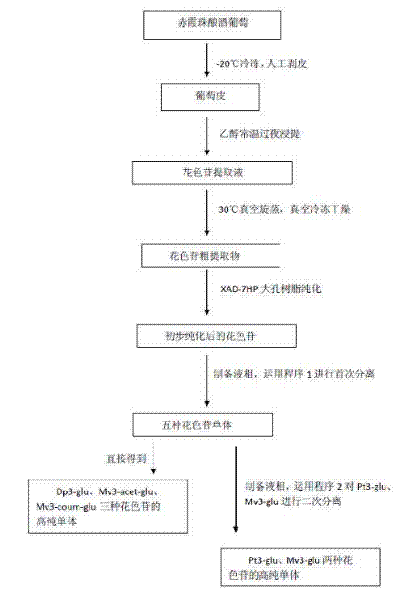

[0032] Embodiment 1: Extraction of grape skin anthocyanins

[0033] Freeze the harvested fresh and ripe Cabernet Sauvignon wine grapes at -20°C. After the freezing is complete, take them out of the refrigerator and place them at room temperature, thaw the peel and peel off the peel (this method can better preserve the peel and pulp. separation without sticking the pulp). The extract is 95% ethanol (analytically pure) containing 1% hydrochloric acid (V / V), and it is leached overnight at 30°C according to the liquid-to-solid ratio of extract:grape skin weight ratio 1.5:1. Filter off the peel and centrifuge at 6000r for 10min to remove the precipitate to obtain the extract.

Embodiment 2

[0034] Embodiment 2: the processing of macroporous resin and the preparation of loading sample

[0035] Soak the XAD-7HP macroporous resin with ethanol (analytical grade) first, and wash it every 12 hours until the eluate is colorless and transparent, and then wash it with deionized water until there is no alcohol. Then soak with 1mol / L NaOH for 12h, and then wash with deionized water to neutral pH. Replace with 1mol / L HCl to soak for 12 hours, and finally wash with deionized water to neutral pH, and pack it into a column for later use.

[0036]The extract obtained from the treatment in Example 1 was vacuum rotary evaporated at 30° C. to remove ethanol, and then vacuum freeze-dried to obtain a crude anthocyanin extract. The crude extract was dissolved in 50% ethanol (analytical grade diluted to 50%, V / V) until the solution was saturated, centrifuged at 8000r for 6min, filtered through a 0.45μm organic microporous membrane and prepared for sample injection.

Embodiment 3

[0037] Embodiment 3: Macroporous resin purifies anthocyanins in grape skin

[0038] Pack the treated XAD-7HP macroporous resin into a column, and equilibrate with 50% ethanol (analytical pure ethanol diluted to 50%, V / V) solution containing 0.1% hydrochloric acid (V / V) for 0.5h. Inject at a flow rate of 0.5BV / h, elute with a solution of 50% ethanol (analytical pure ethanol diluted to 50%, V / V) containing 0.1% hydrochloric acid (V / V) at a flow rate of 1BV / h, and collect the eluate (red) .

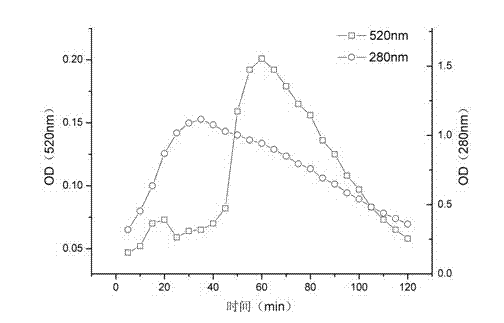

[0039] The characteristic absorption peak of anthocyanin is around 520nm, so the content change of anthocyanin in the eluate is monitored by the spectral absorption signal at 520nm. Impurities with benzene rings have strong spectral absorption at 280nm, so 280nm is used to monitor the content of impurities in the effluent.

[0040] Samples were taken every 5 minutes to measure the absorbance values at 520nm and 280nm since the anthocyanins flowed out, and the collection time was taken as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com