Electrode for realizing ohmic contact with n type ZnS quasi-one-dimensional nanometer material and preparation method thereof

A technology of nano-materials and ohmic contacts, applied in circuits, electrical components, semiconductor devices, etc., to achieve mature and reliable, simple preparation process, and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

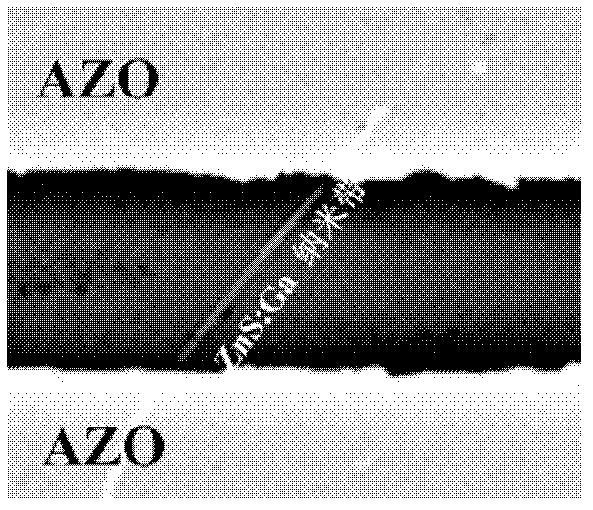

[0027] The doping concentration synthesized by chemical vapor deposition method is 1.0×10 16 cm -3 Ga-doped ZnS nanoribbons uniformly dispersed in SiO with a thickness of 300 nm 2 On the p-type heavily doped Si wafer, the bottom gate of the device is on the p-type heavily doped Si wafer, the photoresist is uniformly spin-coated, and the two-electrode electrode pattern is photo-etched. figure 1 SEM image of the device.

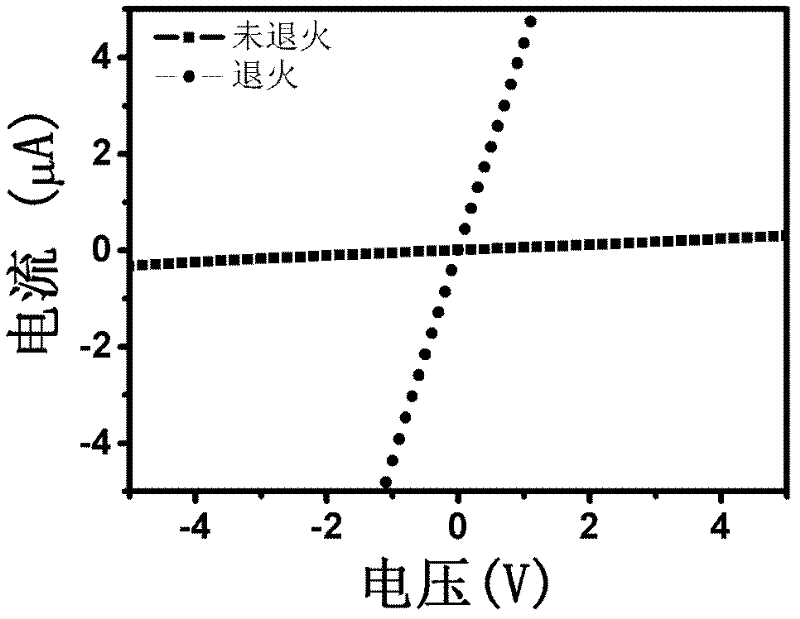

[0028] Using the pulsed laser deposition method, the condition is that the laser energy is 40mJ, the laser wavelength is 248nm, the pulse frequency is 20Hz, and the vacuum degree is 1×10 -5 Pa, deposit a 60nm thick AZO film on the photoetched electrode pattern. In order to further reduce the contact resistance between the AZO electrode and Ga-doped ZnS nanoribbons, the AZO electrode was vacuumed at 10 -4 Under Pa annealing, the annealing temperature is 100° C., and the time is 5 minutes. KEITHLEY 4200 semiconductor characteristic testing system was used to...

Embodiment 2

[0030] The doping concentration synthesized by chemical vapor deposition method is 2.0×10 17 cm -3 Cl-doped ZnS nanowires were uniformly dispersed in SiO with a thickness of 300 nm 2 On the p-type heavily doped Si wafer, the p-type heavily doped Si wafer is the bottom gate of the device, and the photoresist is evenly spin-coated, and the two-electrode electrode pattern is photoetched.

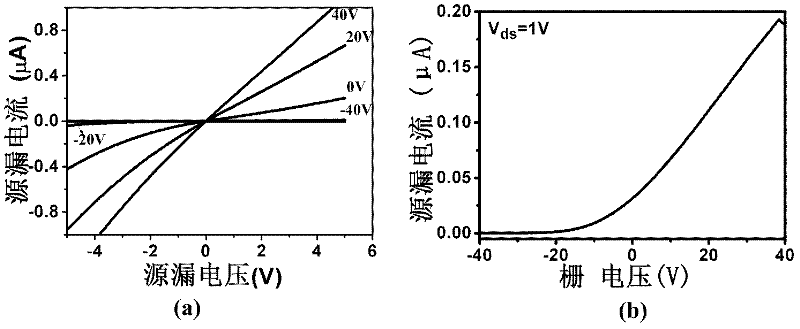

[0031] Using the pulsed laser deposition method, the condition is that the laser energy is 400mJ, the laser wavelength is 248nm, the pulse frequency is 1Hz, and the vacuum degree is 1×10 -2 Pa, deposit a 60nm thick AZO film on the photoetched electrode pattern. In order to further reduce the contact resistance between the AZO electrode and the Cl-doped ZnS nanowires, the AZO electrode was vacuumed at 10 -2 Under Pa annealing, the annealing temperature is 600° C., and the time is 30 minutes. The electrical transport properties of Cl-doped ZnS nanowires were tested by KEITHLEY 4200 semiconduc...

Embodiment 3

[0033] The doping concentration synthesized by chemical vapor deposition method is 6.0×10 15 cm -3 Al-doped ZnS nanoribbons uniformly dispersed in SiO with a thickness of 300 nm 2 On the p-type heavily doped Si wafer, the p-type heavily doped Si wafer is the bottom gate of the device, and the photoresist is evenly spin-coated, and the two-electrode electrode pattern is photoetched.

[0034]Using the magnetron sputtering method, the condition is that the air pressure is 1Pa, the sputtering power is 40W, and the Ar gas flow rate is 10sccm, and a 60nm thick AZO film is deposited on the photoetched electrode pattern. In order to further reduce the contact resistance between the AZO electrode and the Al-doped ZnS nanobelt, the AZO electrode was 2 The annealing is carried out under atmosphere protection, the annealing temperature is 300° C., and the annealing time is 20 minutes. The KEITHLEY 4200 semiconductor characteristic testing system was used to test the electrical transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com