Hollow nanowire-polymer film nuclear shell structure composite material and preparation method thereof

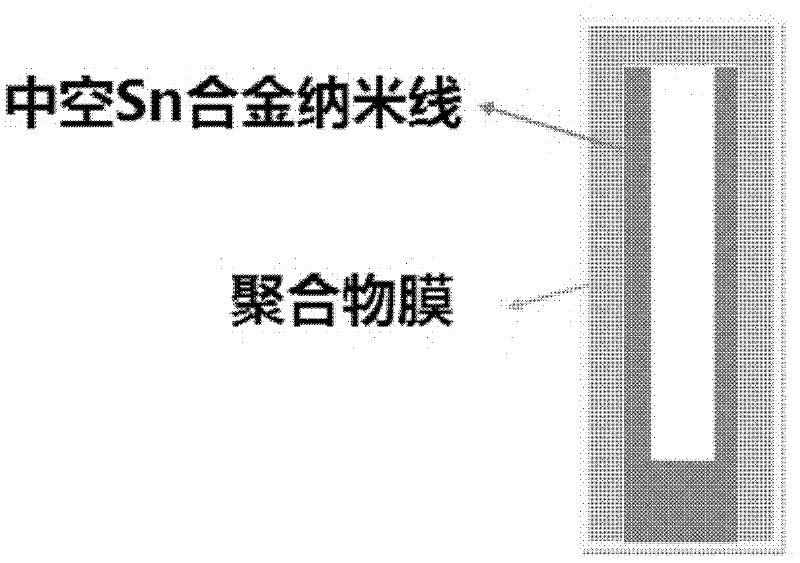

A composite material and core-shell structure technology, applied in the direction of nanotechnology, nanotechnology, structural parts, etc., can solve the problems of poor electrode interface stability and battery capacity decline, so as to improve structural stability, prevent capacity decay, and increase capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

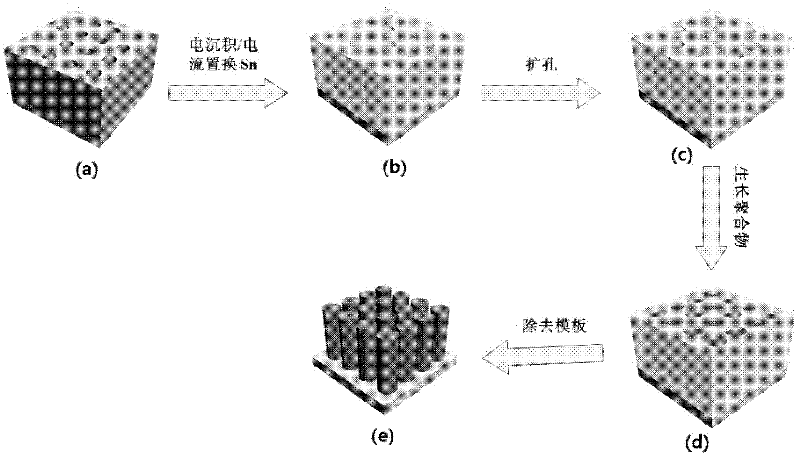

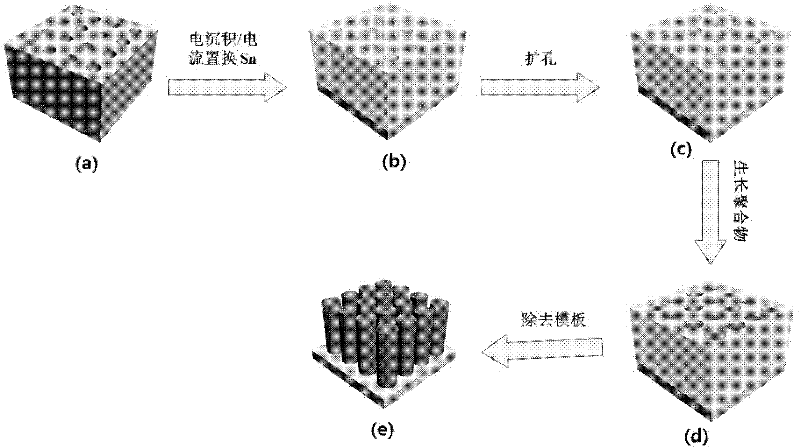

Method used

Image

Examples

Embodiment 1

[0023] The back of the alumina template with a pore size of 200nm is compressed and sealed with a plexiglass nut with a copper electrode inside, and a gold film with a thickness of about 200nm is deposited on the other side of the double-pass alumina template by sputtering. Then place the aluminum oxide template deposited with the gold film in 20mL electrolyte, the composition of the electrolyte (aqueous solution) is 0.1M SnCl 2, 0.3MK 4 P 2 o 7 , 0.1M C 2 h 5 NO 2 and 5M NH 4 In OH, a three-electrode system was adopted, with a gold film covered with an alumina template as the working electrode, a platinum (Pt) wire as the counter electrode, and a saturated calomel electrode as the reference electrode. 2 The tin-based nanowires can be obtained in the alumina template used as the working electrode after deposition for 30 minutes.

[0024] Take out the working electrode, rinse it with distilled water three times, dry it at room temperature, and place it in 0.1M CuSO 4 Af...

Embodiment 2

[0027] The back of the alumina template with a pore size of 200nm is compressed and sealed with a plexiglass nut with a copper electrode inside, and a gold film with a thickness of about 200nm is deposited on the other side of the double-pass alumina template by sputtering. It is then placed in 20mL of electrolyte solution (aqueous solution) consisting of 0.2M SnCl 2 , 0.4M K 4 P 2 o 7 , 0.3M C 2 h 5 NO 2 and 5M NH 4 OH, using a three-electrode system, with a gold film covered with an alumina template as the working electrode, a Pt wire as the counter electrode, and a saturated calomel electrode as the reference electrode. 2 The tin-based nanowires can be obtained in the alumina template used as the working electrode after deposition for 30 minutes.

[0028] Take out the working electrode, rinse it with distilled water three times, and dry it at room temperature. Then place it in 0.1M NiSO 4 After being replaced in the aqueous solution for 30 minutes, the electrode wa...

Embodiment 3

[0031] The back of the alumina template with a pore size of 200nm is compressed and sealed with a plexiglass nut with a copper electrode inside, and a gold film with a thickness of about 200nm is deposited on the other side of the double-pass alumina template by sputtering. It is then placed in 20mL of electrolyte solution (aqueous solution) consisting of 0.2M SnCl 2, , 0.3M K 4 P 2 o 7, , 0.2M C 2 h 5 NO 2 and 5M NH 4 OH, using a three-electrode system, with a gold film covered with an alumina template as the working electrode, a Pt wire as the counter electrode, and a saturated calomel electrode as the reference electrode, at 10mA / cm 2 The tin-based nanowires can be obtained in the alumina template used as the working electrode after deposition for 20 minutes.

[0032] Take out the working electrode, rinse it with distilled water three times, and dry it at room temperature. Then place it in 0.1M NiSO 4 After being replaced in the aqueous solution for 30 minutes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com