A kind of surface iron modified titanium dioxide photocatalyst and its preparation method and application

A titanium dioxide and catalyst technology, applied in the field of photocatalysts, can solve the problems of increasing or reducing the concentration of oxygen defects, different optimal temperatures, weakening the photoactivity of titanium oxide, etc., and achieves a photocatalyst with increased activity, simple preparation method and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

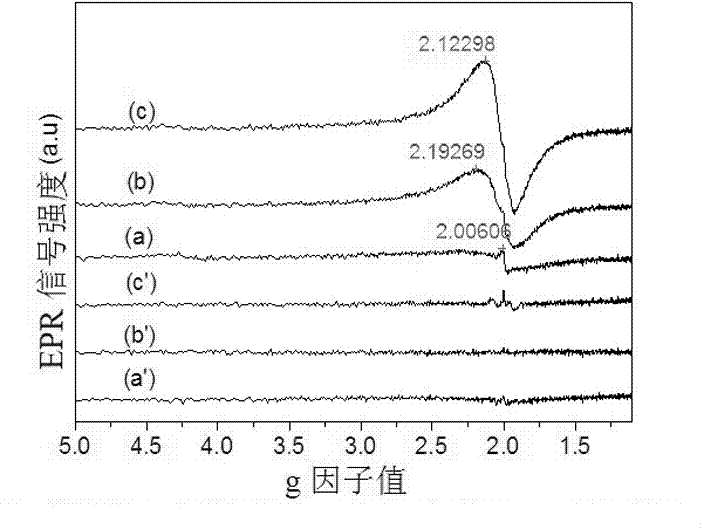

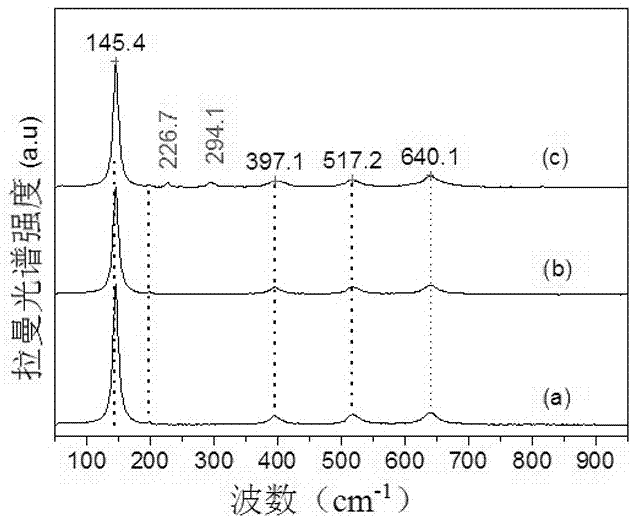

[0039] Using commercial anatase titanium dioxide (CAT) as the titanium source and carboxylated iron phthalocyanine (FeTCPC) as the iron source, the composite photocatalysts of titanium dioxide pretreated at different temperatures and modified with surface iron were prepared by adsorption-ashing method.

[0040] Step 1: At room temperature, weigh 0.250g of CAT that has been pre-calcined at a certain temperature for 3 hours. Evenly dispersed;

[0041] The second step is to ensure a dark environment, and under vigorous stirring, add 25 mL of FeTCPC solution with DMF as the solvent concentration of 100 ppm to the titanium oxide suspension obtained in the first step, and continue to stir in the dark for 12 hours;

[0042] In the third step, FeTCPC can be completely adsorbed to the surface of CAT, the suspension is filtered with suction, washed with deionized water until no DMF exists, and dried at 70°C in the dark;

[0043] The fourth step is to collect the solid samples from the ...

Embodiment 2

[0048] Using commercial anatase titanium dioxide (CAT) as titanium source and carboxylated iron phthalocyanine (FeTCPC) as iron source, the surface iron-modified titanium dioxide composite photocatalysts with different ashing temperatures were prepared by adsorption-ashing method.

[0049] Step 1: At room temperature, weigh 0.250g of CAT that had been pre-calcined at 600°C for 3 hours, put it into 225mL of deionized water, and disperse it evenly by ultrasonication for 5 minutes;

[0050] The second and the third step are the same as embodiment 1;

[0051] The fourth step is to collect the solid samples from the third step and place them in a muffle furnace for ashing at a certain temperature. The temperature can be 300, 400, 500, 600, or 700°C;

[0052] The fifth and sixth steps are the same as in Example 1 to obtain surface iron-modified titanium dioxide and blank titanium dioxide samples treated at different ashing temperatures, which are respectively denoted as Fe x2 / CAT6...

Embodiment 3

[0055] Using commercial anatase titanium dioxide (CAT) as the titanium source and carboxylated iron phthalocyanine (FeTCPC) as the iron source, the surface iron-modified titanium dioxide composite photocatalysts with different iron contents were prepared by adsorption-ashing method.

[0056] The first step is with embodiment 1;

[0057] In the second step, to ensure a light-proof environment, under vigorous stirring, add 25 mL of FeTCPC solution with a certain concentration of pyridine as a solvent to the titanium dioxide suspension obtained in the first step, and continue to stir in the dark for 12 hours. The concentration of FeTCPC (DMF) can be specifically 0, 20, 50, 80, 100, 120, 150, 180, 200, 250, 300, 500ppm;

[0058] The third to fifth steps are the same as in Example 1 to obtain surface iron-modified titanium dioxide composite photocatalysts with different iron contents, which are denoted as Fe400 / CAT600. The mass fraction of iron in the solid is specifically 0, 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com