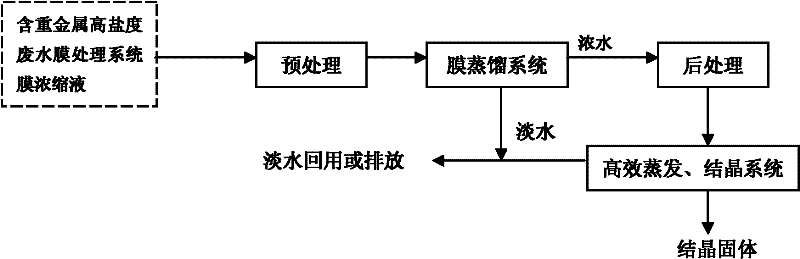

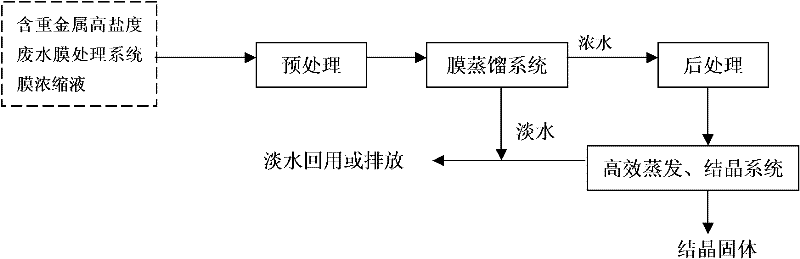

A method for treating heavy metal-containing wastewater membrane filtration concentrate

A technology for concentrated liquid and heavy metals, which is applied in the fields of energy and wastewater treatment, chemical instruments and methods, and multi-stage water/sewage treatment. , improve the utilization rate, the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Wastewater from a lead-zinc smelter, the treatment process is mainly lime (stone) neutralization + oxidation flocculation + membrane treatment, the reverse osmosis membrane filters the concentrated solution, and its water quality indicators: Pb: 0.4774mg / l, Zn: 0.0402mg / l , Cd: 0.1898 mg / l, As: 0.015 mg / l, F: 42.09 mg / l, Cl: 11316 mg / l, Na: 8759 mg / l. Direct contact membrane distillation is used for treatment, and polyvinylidene fluoride (PVDF) microporous membrane is used to control the temperature of the hot side at 60°C and the temperature of the cold side at 10°C. Pickling is used to prevent membrane pollution. The desalination rate of the effluent water quality index at this time At 99.1%, the interception rate of heavy metals is also above 99%. The remaining waste water is concentrated twice by the direct contact membrane distillation method and then treated by a three-effect evaporator to recover salt and useful substances by evaporation and crystallization; the ...

Embodiment 2

[0026]The wastewater from a lead-zinc smelter is mainly treated by lime (stone) neutralization + oxidation flocculation + electrochemical + membrane treatment, and the concentrated solution is filtered by nanofiltration membrane. The water quality indicators: Pb: 0.384mg / l, Zn: 0.0848 mg / l, Cd: 0.0347 mg / l, As: 0.018 mg / l, F: 34.16 mg / l, Cl: 7425 mg / l, Na: 5152 mg / l. Air-gap membrane distillation is used for treatment. Polypropylene (PP) microporous membrane is used to control the temperature of the hot side at 80°C and the temperature of the cold side at 20°C. Backwashing is used to prevent membrane fouling. The desalination rate of the effluent water quality at this time is at 99.3%, the interception rate of heavy metals is also above 99%. After being concentrated 5 times by the air-gap membrane distillation method, the remaining wastewater is treated by a three-effect evaporator, and salt and useful substances are recovered by evaporation and crystallization; the steam cool...

Embodiment 3

[0028] Wastewater from a copper smelter, the treatment process is mainly lime neutralization + sulfide precipitation + membrane treatment, nanofiltration and reverse osmosis membrane filtration mixed concentrate, its water quality indicators: Cu: 0.284mg / l, Pb: 0.184mg / l , Zn: 0.1548mg / l, Cd: 0.0427mg / l, As: 0.028mg / l, F: 30.16mg / l, Cl: 5425mg / l, Na: 4152mg / l. The vacuum membrane distillation method was used for the test, and the polypropylene (PP) microporous membrane was used to control the temperature of the hot side at 90°C, the temperature of the cold side at 10°C, and the vacuum degree of the cold side at 0.15MPa. Ultrasonic cleaning was used to prevent membrane pollution. The desalination rate is 99.6%, and the interception rate of heavy metals is also above 99%. After being concentrated 10 times by the vacuum membrane distillation method, the remaining wastewater is treated by a three-effect evaporator, and salt and useful substances are recovered by evaporation and cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com