A method of using papermaking sludge for desulfurization, denitrification and coal saving in circulating fluidized bed boilers

A technology of circulating fluidized bed and papermaking sludge, which is applied in the direction of combustion method, block/powder fuel preparation, combustion equipment, etc., can solve the problems of high desulfurization cost, reduced desulfurization efficiency, high operating cost, etc., to avoid secondary Secondary pollution, high degree of harmlessness, and the effect of reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

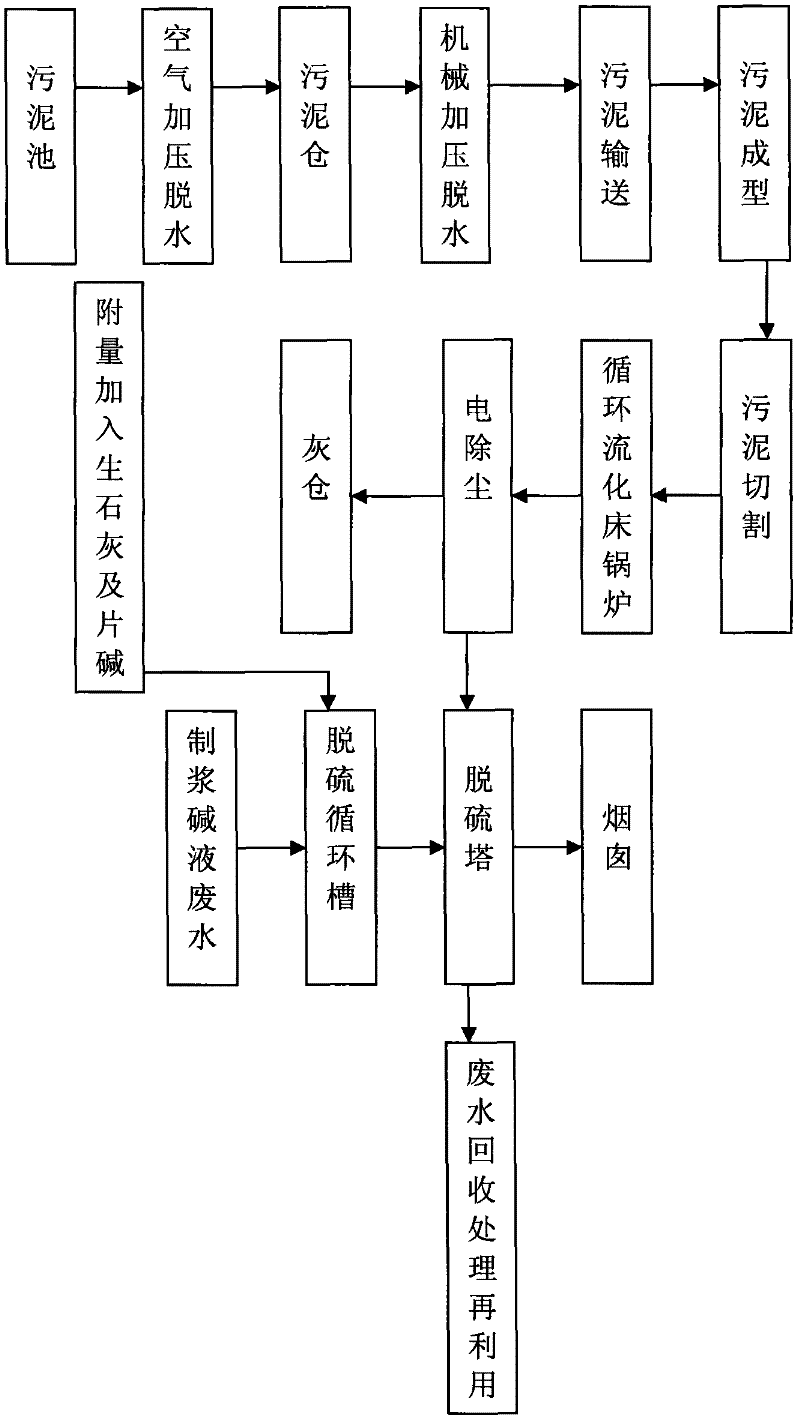

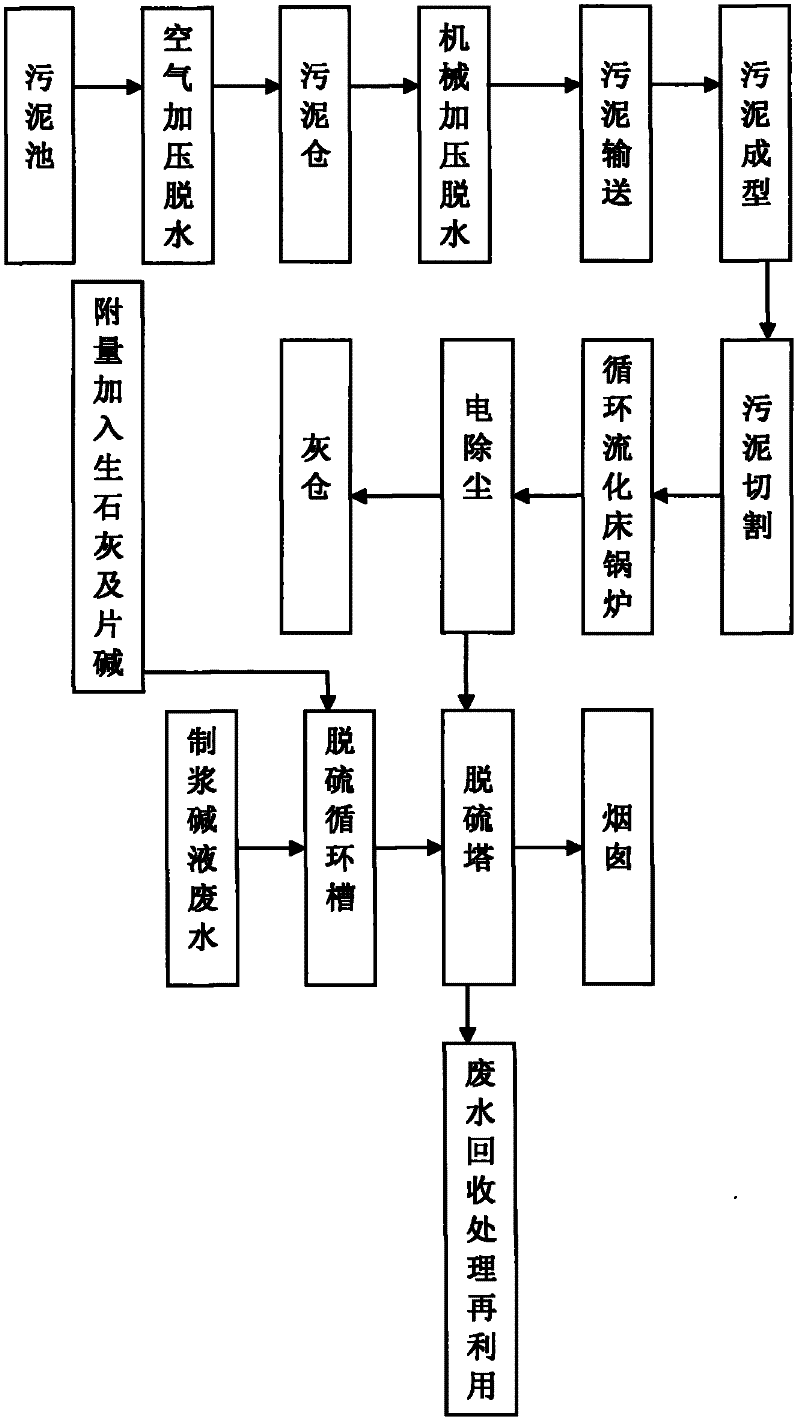

Method used

Image

Examples

Embodiment 1

[0038] Papermaking sludge with a water content of more than 70% (air-drying base composition: CaO 40%, MgO 11%, Fe 2 o 3 0.4%, Al 2 o 3 2.2%, Na 2 O 0.3%), directly carry out air pressurized dehydration treatment, the sludge water content is reduced to below 60%, and the dehydration pressure is 1.3Mpa, and then the secondary dehydration is carried out by mechanical pressurization, and its water content is reduced to below 50%. Use a forming machine to make strips with a diameter of 8mm, and then cut them into 10mm strips with a reamer, and send them to the coal-feeding negative pressure zone of the boiler, where they will be burned together with the coal in the boiler furnace.

[0039] Generally, the sulfur content of coal is 2%-3%. One ton of coal desulfurization and denitrification needs to mix 200 kg of sludge with a water content of about 50%, because the calorific value of sludge is only 800-1000 kcal / kg, the circulating fluidized bed boiler requires the calorific va...

Embodiment 2

[0042] The papermaking sludge (the composition after drying is: CaO 42%, MgO 10%, Fe 2 o 3 0.6%, Al 2 o 3 2.3%, Na 2 O 0.2%), directly carry out air pressurized dehydration treatment, the water content of the sludge is reduced from more than 70% to less than 60%, and the dehydration pressure is 1.3Mpa. 50% or less, use a molding machine to make strips with a diameter of 8mm, and then cut them into 10mm strips with a reamer, and send them to the coal negative pressure zone of the boiler, where they will be burned together with coal in the boiler furnace.

[0043] Generally, the sulfur content of coal is 2%-3%. One ton of coal desulfurization and denitrification needs to mix 200 kg of sludge with a water content of about 50%, because the calorific value of sludge is only 800-1000 kcal / kg, the circulating fluidized bed boiler requires the calorific value of coal and sludge blended to be controlled at 2500-3000 kcal / kg. If the papermaking sludge is mixed too much, it will af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com