A kind of preparation method of mesoporous silica spherical nanoparticles

A mesoporous silica and nanoparticle technology, applied in silica, silica, nanotechnology and other directions, can solve the problems of large pollution, harsh conditions, and large amount of triethanolamine, so as to save tedious steps and simplify operations. Steps, the effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

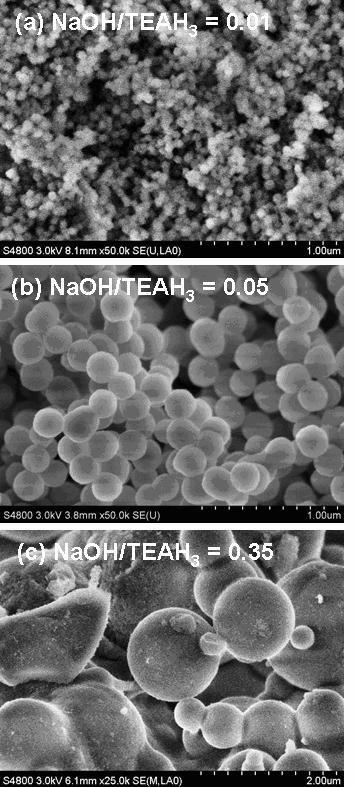

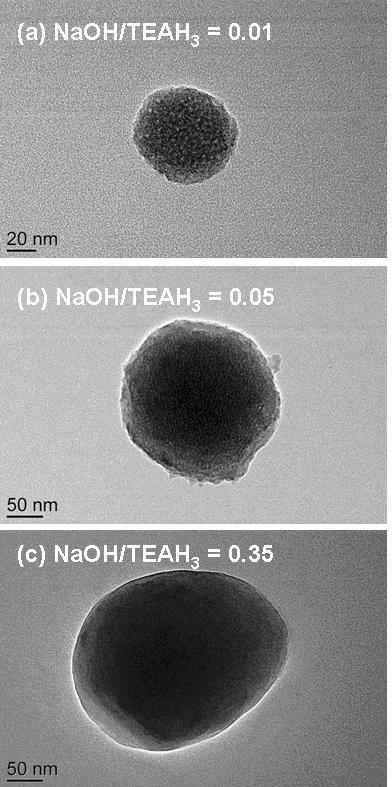

[0019] First, 2.74 g of cetyltrimethyl-p-toluenesulfonate (CTATos) was added to a solution containing 144 ml of deionized water, 0.04 g of sodium hydroxide (NaOH) and 14.92 g of triethanolamine (TEAH 3 ) in a beaker, stirred at 80°C for 1 hour until the solution became clear, then quickly added 20.83g of tetraethoxysilicate (TEOS) into the beaker, and continued to stir at 80°C for 2 hours to obtain a white precipitate. The molar composition of this mixture is SiO 2 :CTATos:TEAH 3 :NaOH:H 2 O = 1:0.06:1:0.01:80; the obtained mixture is directly suction filtered, washed, and dried to obtain mesoporous SiO 2 Nanoparticles, yield 95%, average particle size 60 nm. The method of high-temperature roasting or acid treatment can remove the surfactant in the channel in one step. The specific method is as follows: (1) 1.0g raw powder is directly roasted in a muffle furnace at 550°C for 6 hours; (2) 1.0g raw powder is mixed with 40ml 1M hydrochloric acid ethanol solution, stirred at r...

Embodiment 2

[0021] First, 2.74g of cetyltrimethyl-p-toluenesulfonate (CTATos) was added to a solution containing 144ml of deionized water, 14.92g of triethanolamine (TEAH 3 ) and 0.20g NaOH mixed solution, stirred at 80°C for 1 hour until the solution became clear, then quickly added 20.83g tetraethoxysilicate (TEOS) into the beaker, and continued to stir at 80°C for 2 hours , a white precipitate was obtained, and the molar composition of the mixture was SiO 2 :CTATos:TEAH 3 :NaOH:H 2 O = 1:0.06:1:0.05:80; the obtained mixture is directly suction filtered, washed and dried to obtain mesoporous SiO 2 Nanoparticles, yield 95%, average particle size 180 nm. Change NaOH to TEAH 3 The molar ratio of the mesoporous silica nanoparticles with different particle sizes can be obtained, and the higher the alkalinity, the larger the particle size.

Embodiment 3

[0023] First, 2.74 g of cetyltrimethyl-p-toluenesulfonate (CTATos) was added to a solution containing 144 ml of deionized water, 1.4 g of NaOH and 14.92 g of triethanolamine (TEAH 3 ) mixed solution in a beaker, 80 o Stir at C constant temperature for 1 hour until the solution becomes clear, then quickly add 20.83g tetraethoxysilicate (TEOS) into the beaker, 80 o C constant temperature continued to stir for 2 hours, a white precipitate was obtained, and the molar composition of the mixture was SiO 2 :CTATos:TEAH 3 :NaOH:H 2 O = 1:0.06: 1:0.35:80; the obtained mixture is directly suction filtered, washed and dried to obtain mesoporous SiO 2 Nanoparticles, yield 95%, average particle size 800 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com