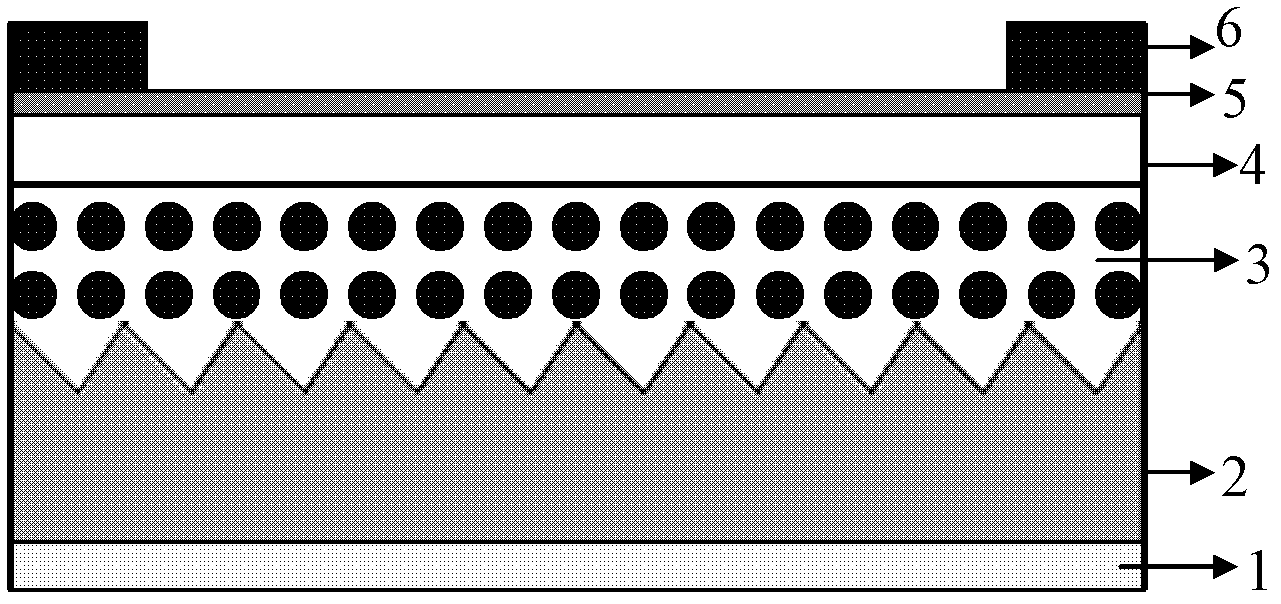

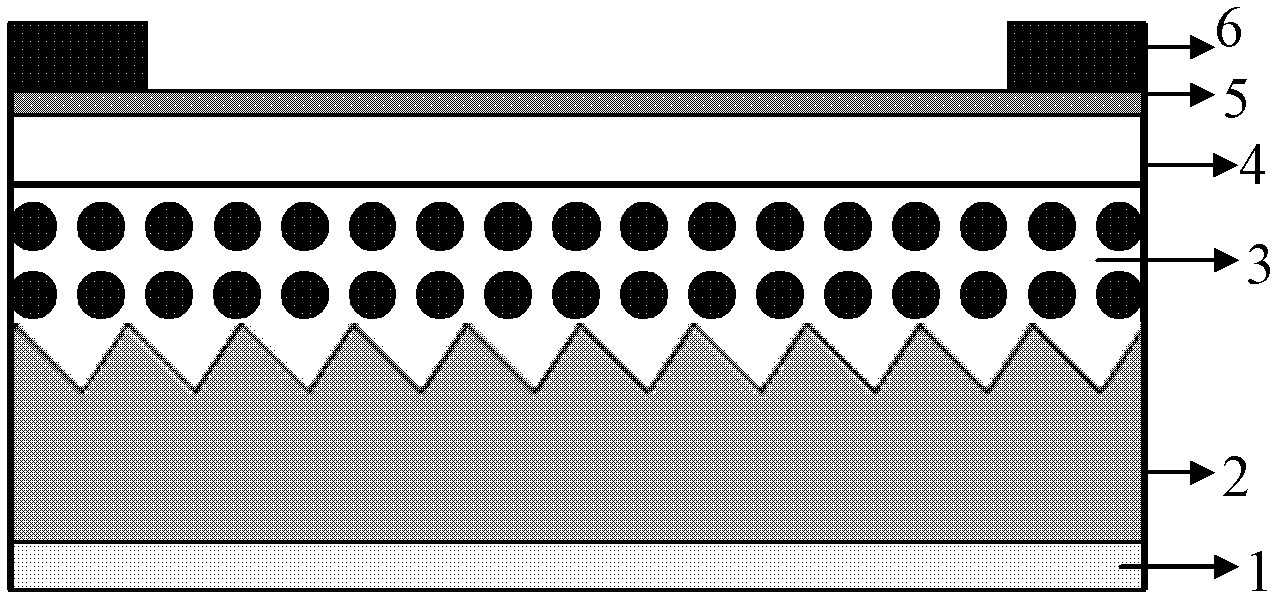

Silicon quantum dot solar cell based on heterojunction structure and preparation method thereof

A technology of solar cells and silicon quantum dots, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of different sub-cell currents and lattice constants, shortage of material sources, environmental pollution, etc., to achieve large quantum yield, Enriching the effect of non-toxic, high transformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) cleaning the P-type monocrystalline silicon substrate;

[0033] (2) A pyramid textured structure is prepared on a P-type monocrystalline silicon substrate, and the chemical solvent used for the texture is a prepared solution of potassium hydroxide, deionized water and isopropanol. Wherein, the volumes of deionized water and isopropanol required per gram of potassium hydroxide are: 0.35ml and 1.86ml respectively. The P-type monocrystalline silicon substrate is placed in the prepared chemical solvent and kept in a constant temperature water bath at 75°C for 45 minutes to form a pyramid with an average height of 10-15um, and obtain the P-type monocrystalline silicon substrate 2;

[0034] (3) implement NH to the monocrystalline silicon substrate 2 that makes pyramid suede finish 3 Plasma treatment for 8 minutes, in which NH 3 The flow rate is 45sccm, the RF power is 40W, the substrate temperature is 200°C, and the pressure is 60Pa;

[0035] (4) A non-stoichiometric s...

Embodiment 2

[0042] (1) cleaning the P-type monocrystalline silicon substrate;

[0043] (2) A pyramid textured structure is prepared on a P-type monocrystalline silicon substrate, and the chemical solvent used for the texture is a prepared solution of potassium hydroxide, deionized water and isopropanol. Wherein, the volumes of deionized water and isopropanol required per gram of potassium hydroxide are: 0.37ml and 1.75ml respectively. The P-type monocrystalline silicon substrate is placed in the prepared chemical solvent and kept in a constant temperature water bath at 80°C for 50 minutes, and the average height of the pyramids formed is between 10-17um, and the P-type monocrystalline silicon substrate 2 is obtained;

[0044] (3) implement NH to the monocrystalline silicon substrate 2 that makes pyramid suede finish 3 Plasma treatment for 9 minutes, in which NH 3 The flow rate is 55sccm, the RF power is 60W, the substrate temperature is 220°C, and the pressure is 60Pa;

[0045] (4) A n...

Embodiment 3

[0052] (1) cleaning the P-type monocrystalline silicon substrate;

[0053] (2) A pyramid textured structure is prepared on a P-type monocrystalline silicon substrate, and the chemical solvent used for the texture is a prepared solution of potassium hydroxide, deionized water and isopropanol. Wherein, the volumes of deionized water and isopropanol required per gram of potassium hydroxide are respectively: 0.38ml and 1.67ml. The P-type monocrystalline silicon substrate is placed in the prepared chemical solvent and kept in a constant temperature water bath at 85°C for 55 minutes to form a pyramid with an average height of 10-20um, and obtain the P-type monocrystalline silicon substrate 2;

[0054] (3) implement NH to the monocrystalline silicon substrate 2 that makes pyramid suede finish 3 Plasma treatment for 10 minutes, in which NH 3 The flow rate is 65sccm, the RF power is 40W, the substrate temperature is 220°C, and the pressure is 70Pa;

[0055] (4) A non-stoichiometric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com