Olefin polymerization catalyst containing beta-diketone metal complex, preparation and application thereof

A metal complex and olefin polymerization technology, which is applied in the field of olefin polymerization catalysts containing β-diketone metal complexes and its preparation and application, and can solve the problems of rare olefin polymerization catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

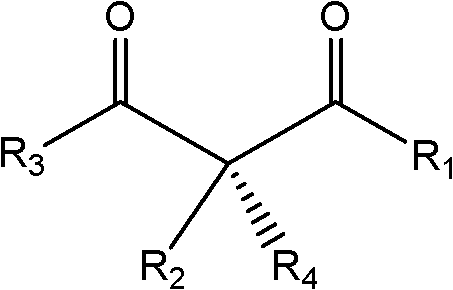

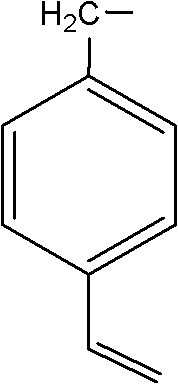

[0021] Add 35.0mmol potassium carbonate and 70.0mmol potassium iodide into a 500mL three-neck flask, under a nitrogen atmosphere and electromagnetic stirring, add the acetone solution of acetylacetone (75.0mmol acetylacetone is dissolved in 100mL acetone solution) and keep warm at 40-65°C 20 minutes. Then, add an acetone solution of 4-chloromethylstyrene (70.0mmol 4-chloromethylstyrene is dissolved in 40mL acetone), and react under a nitrogen atmosphere at a temperature of 50-80° C. for 12-24 hours. After the reaction was finished, the acetone was removed by rotary evaporation. The product was dissolved in 100 mL of ether, washed with 50 mL of distilled water to remove potassium carbonate and potassium iodide, and the washing was repeated 5 times. Ether was removed by rotary evaporation, and 14.1 g of yellow oily substance A was obtained by drying 1 [3-(4-vinylbenzyl)-2,4-pentanedione, its structure is shown in formula I, wherein R 1 =CH 3 , R 2 = H, R 3 =CH 3 ], yield ...

Embodiment 2

[0023] Replace the acetylacetone in Example 1 with 1,1,1,5,5,5-hexafluoroacetylacetone, and the operation is the same as in Example 1. Obtained 21.6 g of yellow oily substance A 2 [3-(4-vinylbenzyl)-1,1,1,5,5,5-hexafluoro-2,4-pentanedione, its structure is shown in formula I, wherein R 1 = CF 3 , R 2 = H, R 3 = CF 3 ], yield 95%.

Embodiment 3

[0025] Synthesis of poly[3-(4-vinylbenzyl)-2,4-pentanedione]-co-polystyrene caged polymer microspheres containing β-diketone ligands (A / B monomer molar ratio is 1:1).

[0026] Add 5.0 mmol of methacrylic acid and 50-150 mL of water into the flask, and stir to dissolve. With stirring, 50.0 mmol of styrene and 2.0 mmol of potassium, sodium or ammonium persulfate were added. Dissolved oxygen in the reaction solution was removed by passing nitrogen gas, and the flask was placed in a water bath at 60-90° C., and reacted for 12-24 hours under a nitrogen atmosphere. After the reaction, centrifuge, wash with water, and dry to obtain 5.0 g of polystyrene-co-polymethacrylic acid microspheres. Get 1.0g of polystyrene-co-polymethacrylic acid microspheres and disperse them in 100mL of water, then add 0.48mmol of potassium persulfate, sodium persulfate or ammonium persulfate, 12.0mmol of β-diketone prepared according to Example 1 Ligand Alkene A 1 , 12.0 mmol of styrene and 1.2 mmol of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com