Cast coke brick and its production method

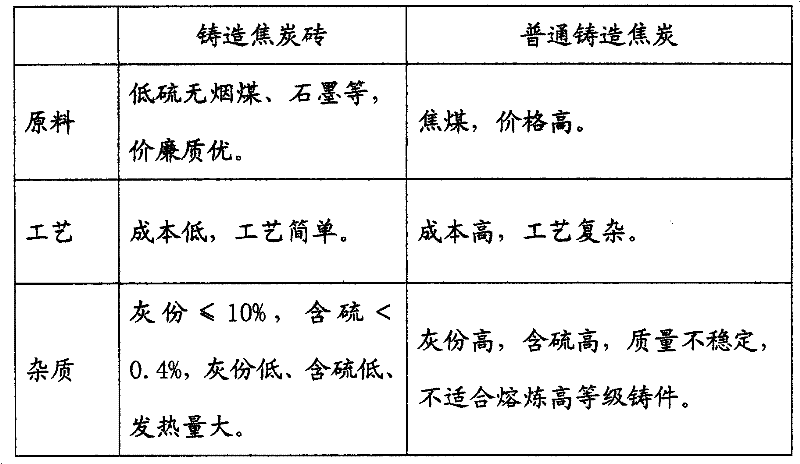

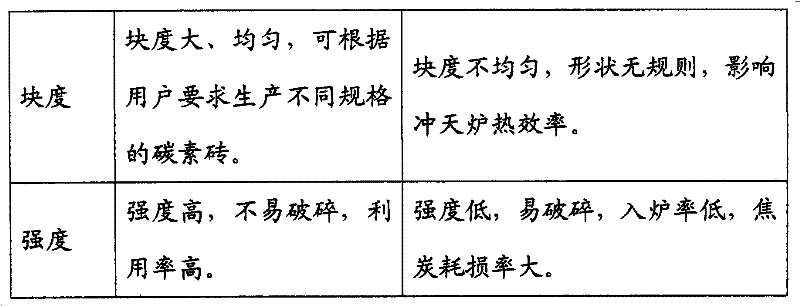

A production method and technology for coke bricks, which are used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of insufficient calorific value, high coke consumption rate and high production cost, and achieve high calorific value, sufficient combustion, and high production efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Low-sulfur anthracite coal enters the coal hopper, and the coal in the hopper is fed into the winnowing crusher for crushing through electromagnetic vibration feeding, with a diameter of 0.5-1 mm. The crushed coal is classified by the wind cyclone separator, the qualified material is discharged into the silo, and the coarse unqualified coal is returned to the pulverizer for further crushing. The pulverized coal in the silo is lifted into the hopper through the bucket elevator, and the pulverized coal in the bucket is fed into the preheating dryer through the disc feeder for preheating and drying, and then mixed with graphite, tar, The waste paper paddles are mixed together in the SH-10 kneading mixer, and then punched and formed by a pressure forming machine. The kiln is heated to 800°C for 9 days of carbonization, and the cast coke brick is obtained when it is naturally lowered to room temperature. The proportion of graphite, tar, and waste paper pulp is ...

Embodiment 2

[0015] Embodiment 2: The diameter of the pulverized low-sulfur anthracite is 1-2 mm. The kiln heating temperature is 1000 ℃, carbonization for 6 days. The ratio of graphite, tar, and waste paper pulp is by weight: 62% of low-sulfur anthracite, 15% of graphite, 2.5% of tar, and the balance is waste paper pulp. All the other are with embodiment 1.

Embodiment 3

[0016] Embodiment 3: The diameter of the pulverized low-sulfur anthracite is 0.5-1.5 mm. The temperature of kiln heating is 900 ℃, carbonization is 8 days. The ratio of graphite, tar, and waste paper pulp is by weight: 65% of low-sulfur anthracite, 12% of graphite, 3% of tar, and the balance is waste paper pulp. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com