Carbon-free engine

An engine and carbon deposition technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of reduced engine life, loss of lubrication function, black smoke from exhaust pipes, etc., to prevent high-temperature sintering carbon deposition, Increase the heat exchange area and enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

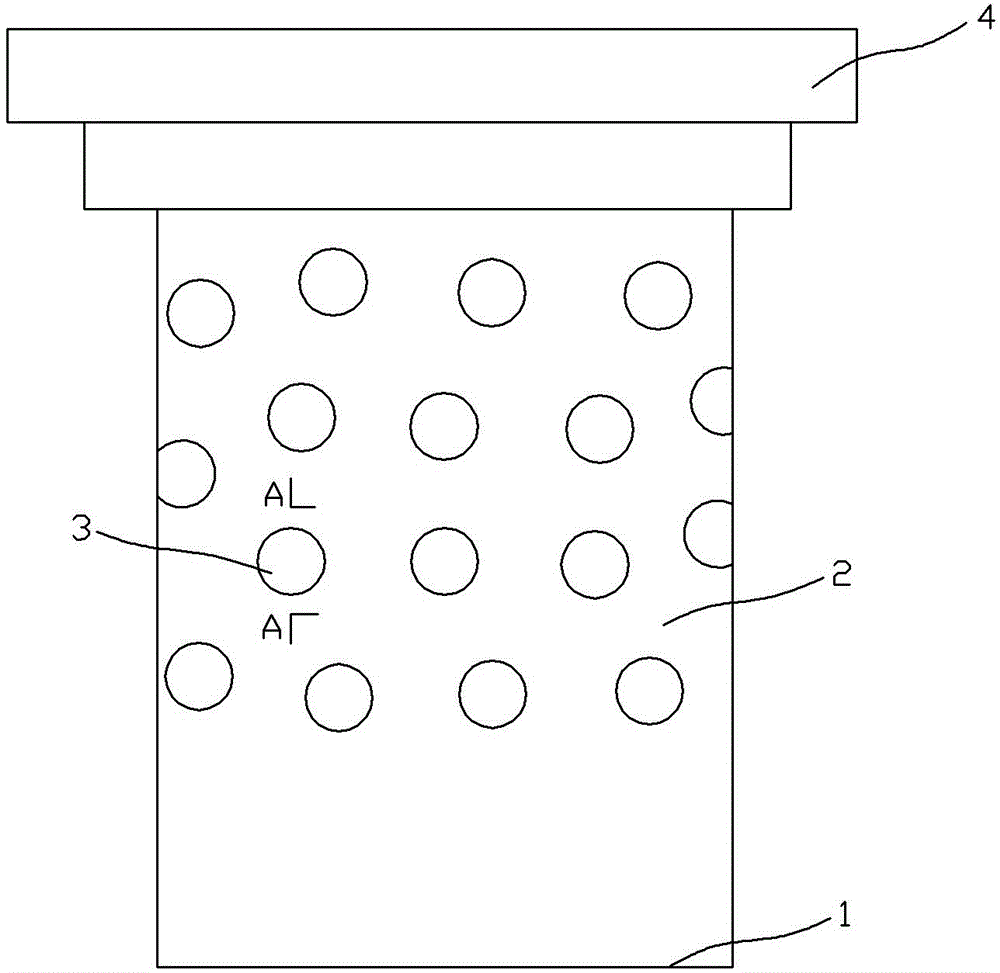

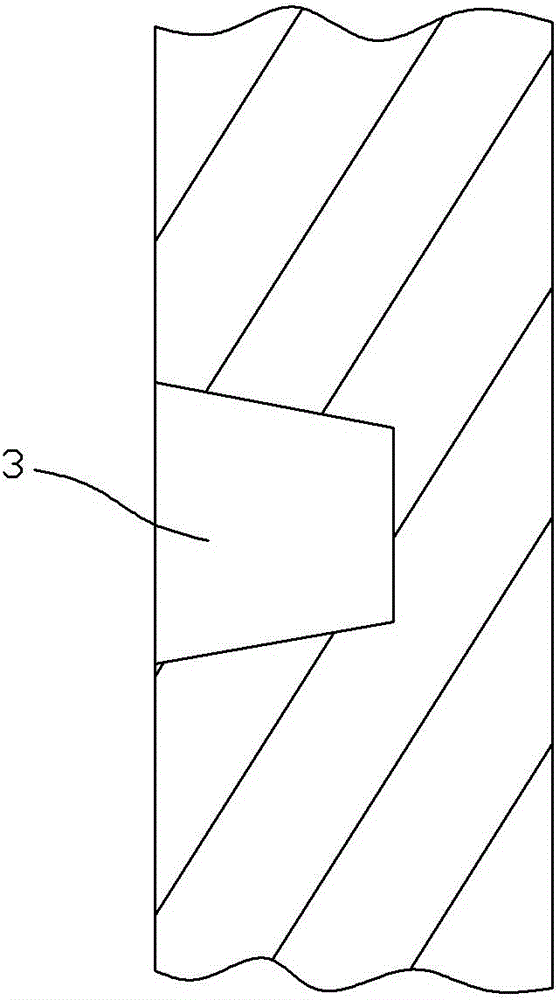

[0027] Example 1 A carbon-free engine, see figure 1 , figure 2 , including a single cylinder 2, a certain number of conical grooves 3 are evenly distributed on the outer wall of the cylinder 2 in contact with cooling water, the diameter of the upper end is 4mm, the diameter of the lower end is 2mm, and the depth is 3mm. The pitch is 12mm. The outer wall of the cylinder and the surface of the groove are nitriding layers to improve the surface hardness and smoothness, which can effectively resist the cavitation of the outer wall of the cylinder. The cylinder increases the contact area between the outer wall of the cylinder and the cooling water through the circular truncated groove, so that the high temperature in the cylinder can be greatly reduced (can be reduced by 500-700°C), and the temperature of sintering carbon deposits in the cylinder cannot be reached and no longer Carbon deposits are produced.

Embodiment 2

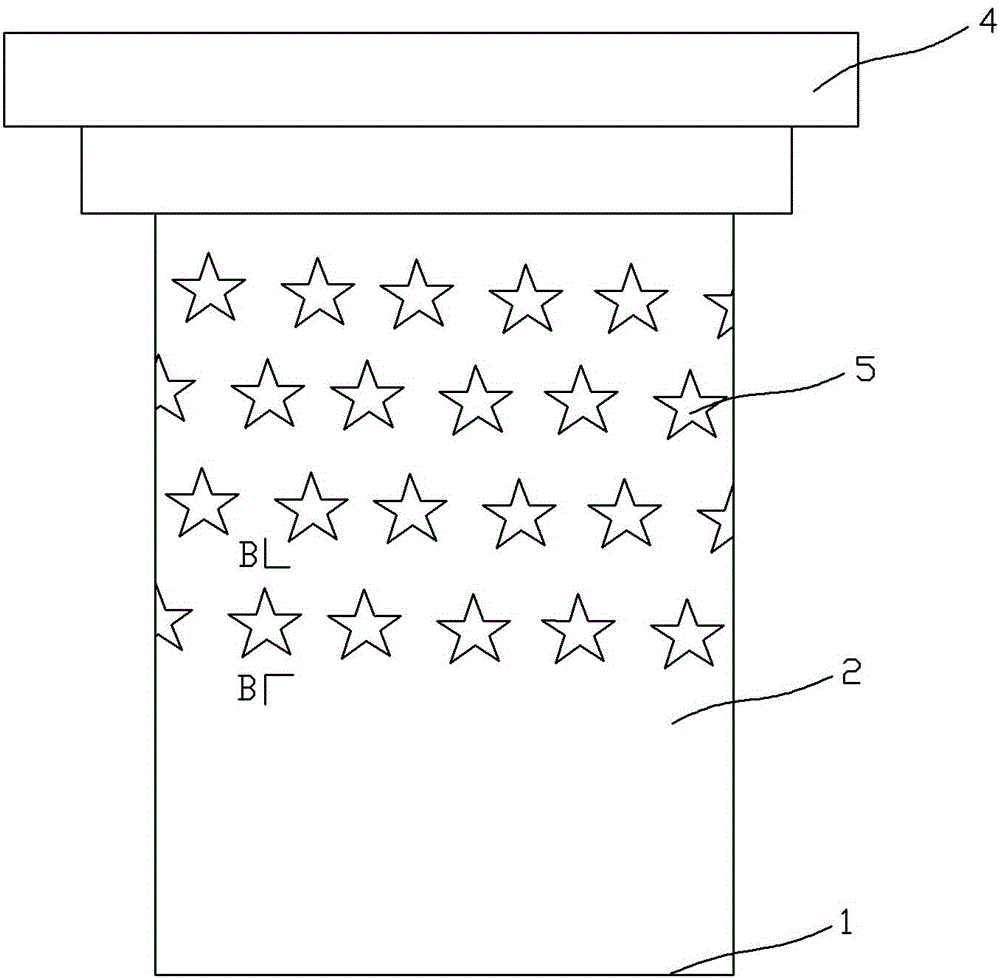

[0028] Embodiment 2 A carbon-free engine, see image 3 , Figure 4 , is basically the same as that of Embodiment 1, except that the groove on the outer wall of the cylinder is in the shape of a five-pointed star.

Embodiment 3

[0029] Embodiment 3 A carbon-free engine, see Figure 5 , Figure 6 , including the cylinder block 6, the cylinder block 6 is provided with a water-cooled cavity 7 and four liner holes 8, and each liner hole is matched with a cylinder (not shown in the figure) installed, in contact with the cooling water A certain number of through-holes 9 are provided on the wall of the cylinder liner hole 9. When the cylinder is put into the cylinder liner hole, the cylinder wall and the cylinder liner hole are closely combined to form a groove structure basically the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com