A graphene-modified lithium iron phosphate/carbon composite material and its application

A carbon composite material and graphene modification technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low diffusion and transmission rate of electrons and Li+, uneven battery current density, capacity attenuation, etc., to improve charging Discharge efficiency and cycle stability, improvement of high-power charge-discharge performance, effect of improved charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

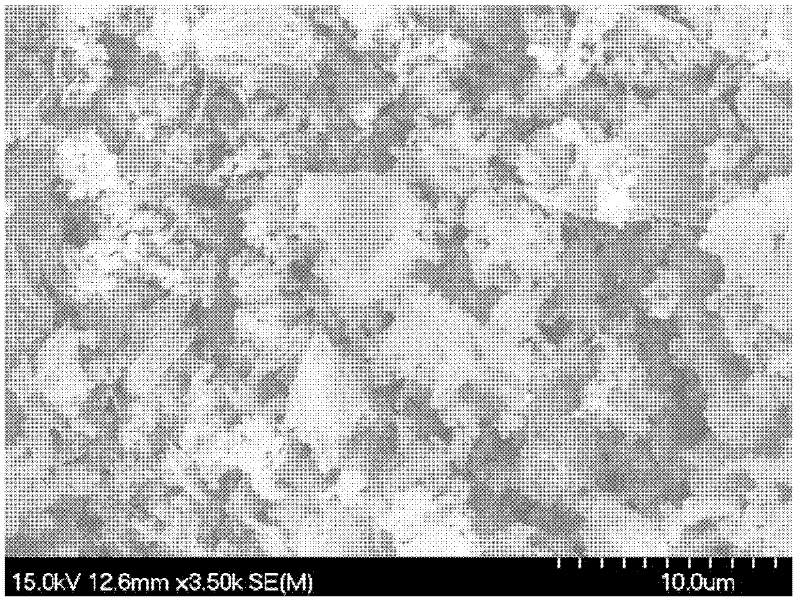

[0041] The first step is to prepare graphite oxide: weigh 4g of graphite, 2g of sodium nitrate, and 92ml of concentrated sulfuric acid (95-98wt.%) in an ice bath, mix well and slowly add 12g of potassium permanganate. Then the system was raised to about 35°C and stirred for 5h. Then slowly add 184ml of distilled water to cause boiling, and continue to stir for 1h. Add 300ml of hot distilled water and 20ml of hydrogen peroxide (30wt.%), centrifuge while hot until the bubbles disappear, wash the product with dilute hydrochloric acid and distilled water until the pH is neutral, and dry part of the graphite oxide dispersion at 60°C.

[0042] The second step is to prepare graphene: Weigh the dispersion containing 100mg of graphite oxide and perform ultrasonication for 5h, then add 1ml of hydrazine hydrate for reduction, the temperature is 100°C, and the time is 24h. The product was filtered and dried at 40°C.

[0043] In the third step, solvothermal in-situ synthesis of lithium i...

Embodiment 2

[0047] The first step is the same as the first step in Example 1, preparing graphite oxide.

[0048] The second step is to weigh 200mg of graphite oxide solid, place it in a muffle furnace at 1050°C for 30s of thermal exfoliation, then weigh 100mg of thermally exfoliated graphite oxide and place it in a mixed solvent of ethanol and water for ultrasonication for 3h, and place Add 1ml of hydrazine hydrate to the dispersion liquid obtained by ultrasonication for reduction, the temperature is 80°C, and the time is 12h. The product was filtered and dried at 40°C.

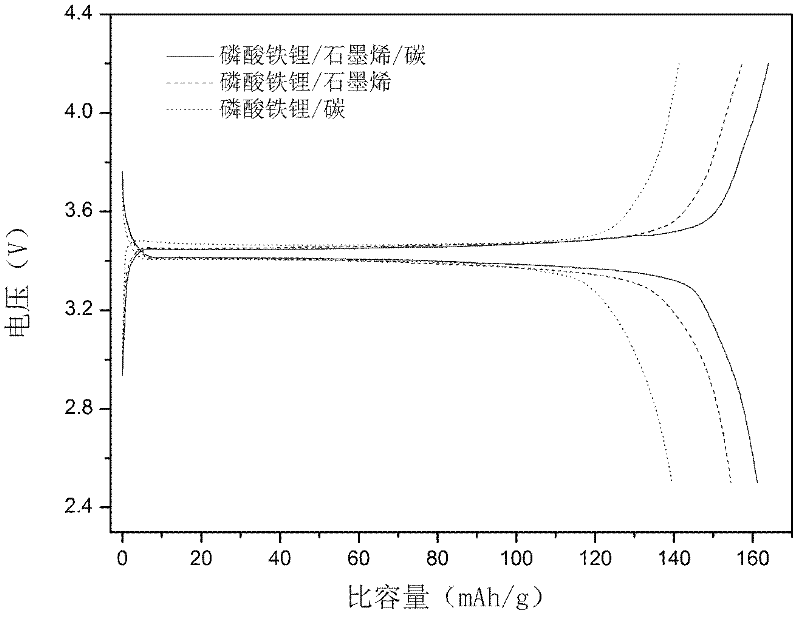

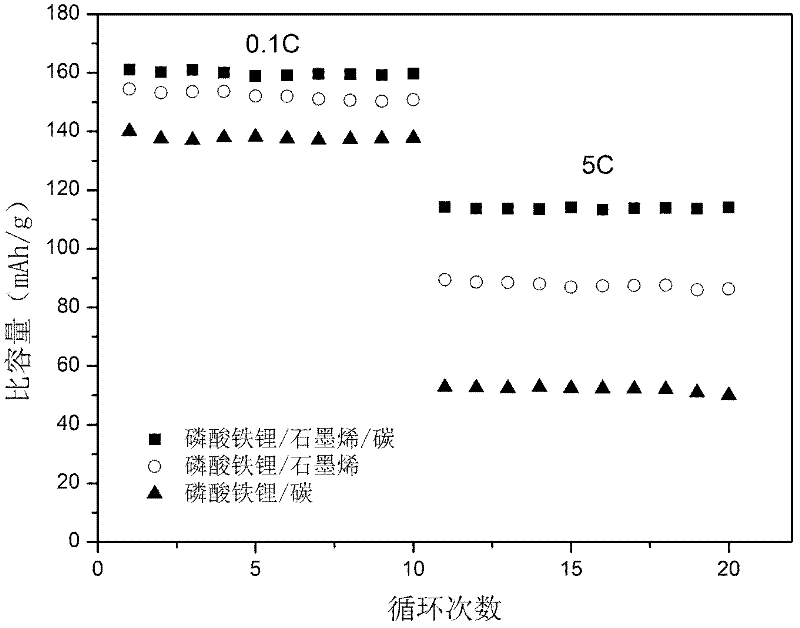

[0049] Subsequent steps are the same as the third, fourth and fifth steps in Example 1. The specific capacities of the obtained products are about 160 and 111mAh / g when discharged at 0.1C and 5C, respectively.

Embodiment 3

[0051] The preparation method is basically the same as in Example 1, except that the powder calcining temperature in the fourth step is 650° C. for 2 hours. The specific capacities of the obtained products are about 158 and 108mAh / g when discharged at 0.1C and 5C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com