Molten pool melting method of bismuth sulphide concentrate

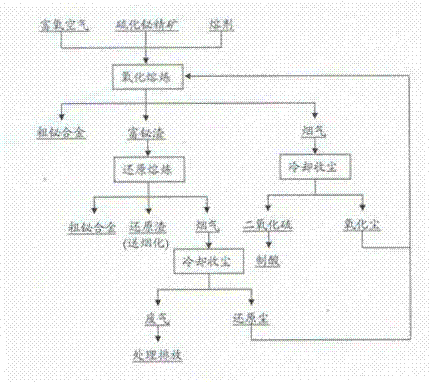

A molten pool smelting and bismuth sulfide technology, which is applied in the field of pyrometallurgical process, can solve the problems of low bismuth recovery rate, large consumption of reagents, high cost, etc., solve the problem of low-concentration SO2 pollution, improve the recovery rate of bismuth smelting, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main components of bismuth sulfide concentrate are: Bi42.55%, S20.79%, Pb5.39%, Cu3.70%, Ag815g / t, Fe3.30%, SiO 2 1.63%; industrial oxygen, of which O 2 Content ≥ 99%; the main components of oxidation smelting bottom slag are: Bi33.6%, FeO20.5%, SiO 2 14.1%, CaO10.6%; the main components of reduction smelting bottom slag are: Bi4.5%, FeO31.2%, SiO 2 21.5%, CaO16.1%; quartz sand its SiO 2 The content of C is 96%; the content of C in pulverized coal is 70%.

[0037]Mix 500g of the above-mentioned bismuth sulfide concentrate with 40g of quartz sand. Control the particle size of the charge to be 10mm, with a water content of 8%, add it to 2000g of the above-mentioned molten oxidation smelting bottom slag, and at the same time blow 95% oxygen-enriched air at 1200°C for oxidation and smelting, stop the introduction of oxygen-enriched air after smelting for 60 minutes, and put it in the furnace After clarification for 20min, 426g of thick bismuth alloy was obtained, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com