Paper filter material containing polyester fibers for cigarette filter tip and preparation method thereof

A polyester fiber and cigarette filter technology, applied in e-liquid filter elements, applications, tobacco, etc., can solve the problems of unstable chemical properties of acetate fibers, affecting the strength of cigarette smoking paper, and easy deacetylation, etc. Good shrinkage, high fiber fineness, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

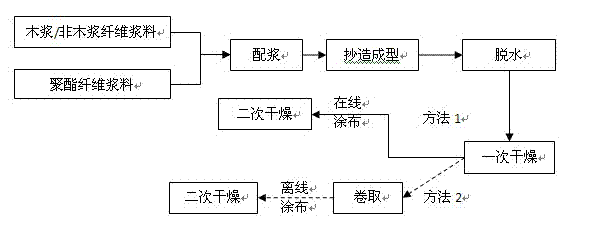

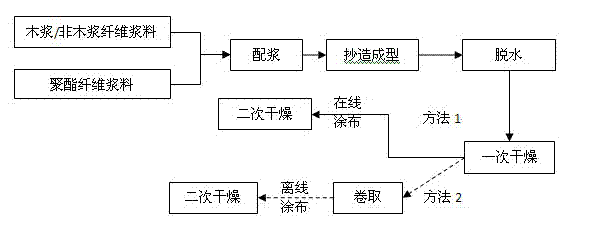

[0031] Polyester fiber staple fibers with a specification of 2 denier and a length of 6 mm such as polyethylene terephthalate (PET) fibers are used, and the functional additive soybean polypeptide equivalent to 1% of the weight of polyester fibers is used. figure 1 As shown, polyethylene terephthalate fibers are added with functional additives for grinding to obtain polyester fiber pulp. Meanwhile, the non-wood pulp fiber straw pulp fiber slurry is prepared in addition or the finished product is directly purchased from the market. Mix the polyester fiber slurry and the straw fiber slurry in the ratio of polyester fiber slurry: straw fiber slurry = 30:70 in the mixing pool, and then use a paper machine to form and dehydrate , after drying once to obtain dry paper, the water-soluble chitosan solution of the coating material is coated on the paper surface according to 1% of the weight of the dry paper online, or the dry paper is rolled up and then coated offline on the paper surf...

Embodiment 2

[0033] Use polyester fibers with a specification of 0.6 denier such as poly(β-hydroxybutyrate) (β-PHB) fibers and pre-cut them to 8mm, add polyvinyl alcohol as a functional additive of 0.5% by weight of polyester fibers, and grind the paddles. Obtain polyester fiber slurry. Then, add prepared softwood pulp fiber, hardwood pulp fiber, according to the percentage ratio, softwood pulp fiber slurry: hardwood pulp fiber slurry: polyester fiber slurry=32:38:30 in the mixing tank Mix evenly with slurry. according to figure 1 As shown, use a paper machine to make a shape, dehydrate and dry once to obtain a dry paper, use a coating material macrostigmatrienone-polyethylene glycol aqueous solution of 0.1% by weight of the dry paper and apply it on the dry paper, and then After secondary drying, the quantitative value is 30g / m 2 , The finished paper filter material containing polyester fiber with a thickness of 0.1mm.

Embodiment 3

[0035]Adopt the polyester fiber that specification is 6 deniers and pre-cut to 3mm such as polyethylene terephthalate (PET) fiber, add the functional auxiliary agent soluble starch of 0.1% of polyester fiber weight, carry out paddle grinding, obtain poly Ester fiber size. Then, add prepared tobacco fiber slurry, coniferous wood pulp fiber, hardwood pulp fiber, according to percentage, tobacco fiber slurry: coniferous wood pulp fiber: hardwood pulp fiber slurry: polyester fiber slurry=10: 25:45:20 Mix the pulp evenly in the pulp mixing tank. Use a paper machine to make a shape, after dehydration and primary drying to obtain dry paper, apply the Zimbabwean tobacco extract solution on the dry paper according to 5% of the dry paper weight, and then dry it twice to obtain a weight of 150g / m 2 , A paper filter material containing polyester fiber with a thickness of 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com