Biological oil spilling dispersing agent and preparation method thereof

A biological, oil-spill technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of only transferring pollution but not degrading pollution, long treatment time period, and slow oil spill degradation speed, etc., and achieves excellent emulsification and dispersion characteristics , good emulsification, reduce the effect of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of biological oil spill dispersant: In this embodiment, biological oil spill dispersant is composed of main agent, auxiliary agent and microorganism, and its weight composition ratio is as follows, containing rhamnolipid 5%, polyoxyethylene ether sorbitol Anhydride Oleate 5%, Sorbitan Oleate 5%, Bacillus WB1 1%, Bacillus WB2 1%, Saccharomyces MTH-81%, Vitamin B1 0.1%, Isopropyl Alcohol 2%, Ethylene Glycol Butyl Ether 2%, water 77.9%.

[0024] When preparing, first clean the batching tank with distilled water, then add 779 grams of pure distilled water to it, followed by 50 grams of rhamnolipid, 50 grams of polyoxyethylene ether sorbitan oleate, and 50 grams of sorbitan oleate Add the proportion of the main agent components into the batching tank and stir well; add 1 gram of vitamin B1, 20 grams of isopropanol, 20 grams of ethylene glycol butyl ether and other auxiliary components directly into the diluted main agent according to the weight composition ratio ...

Embodiment 2

[0026] Preparation of biological oil spill dispersant: In this embodiment, the biological oil spill dispersant is composed of main agent, auxiliary agent and microorganism, and its weight composition composition ratio is as follows, containing 10% of alkyl glucoside, polyoxyethylene ether sorbic acid Alcohol Anhydride Oleate 2%, Polyoxyethylene Oleate 2%, Sorbitan Oleate 2%, Bacillus WB1 1%, Bacillus WB2 1%, Yeast Powder 0.1%, Urea 0.2%, Phosphatidylglycerol 0.2%, butyl glycol ether 5%, water 76.5%.

[0027] When preparing, first clean the batching tank with distilled water, then add 4225 grams of pure distilled water to it, and then follow the steps of 500 grams of alkyl glucoside, 100 grams of polyoxyethylene ether sorbitan oleate, and 100 grams of polyoxyethylene oleate. Add 100 grams of sorbitan oleate and 250 grams of butyl glycol ether into the batching tank and stir well; add 5 grams of yeast powder, 10 grams of urea, 10 grams of phosphatidylethanolamine and other auxil...

Embodiment 4

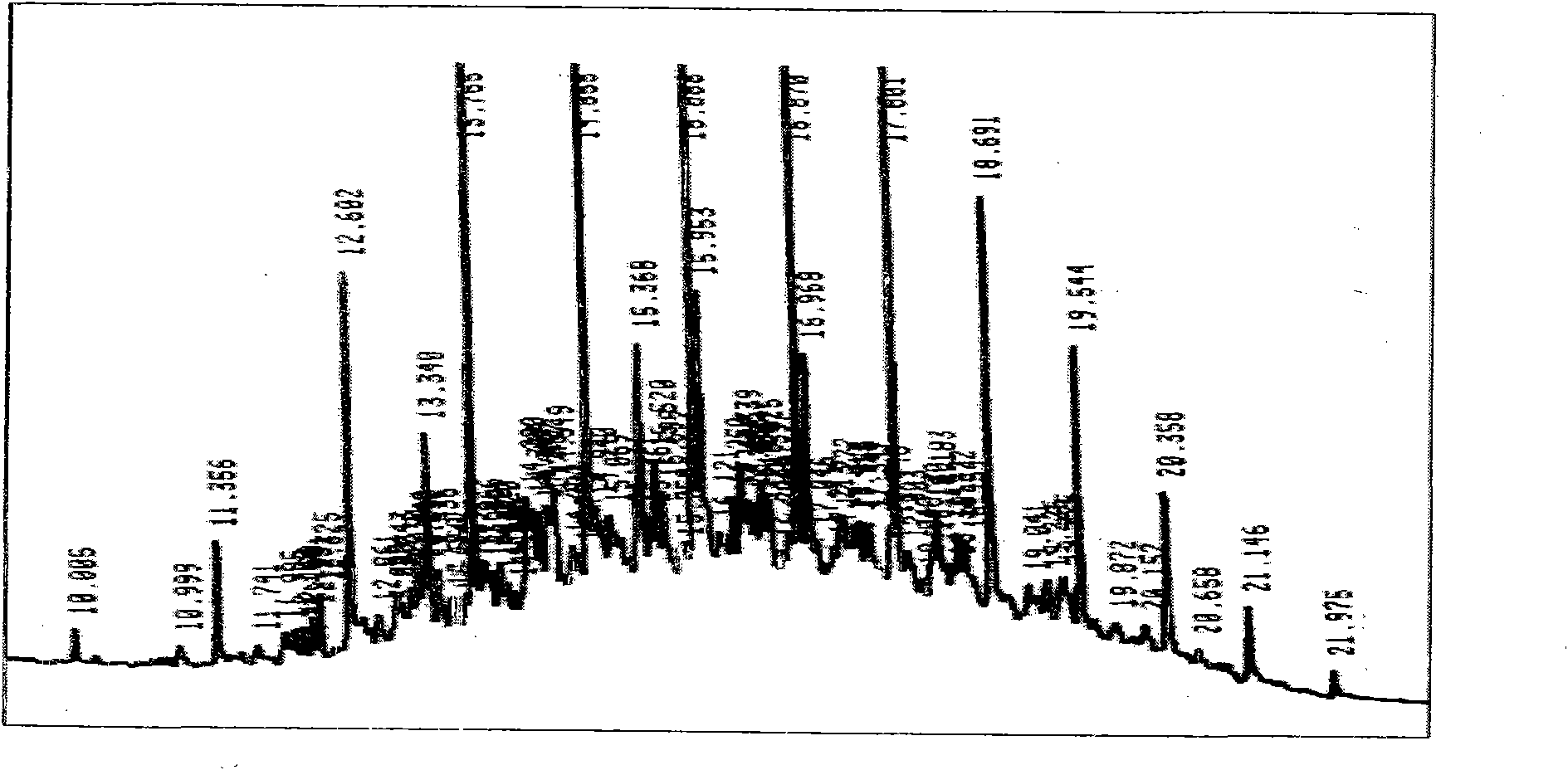

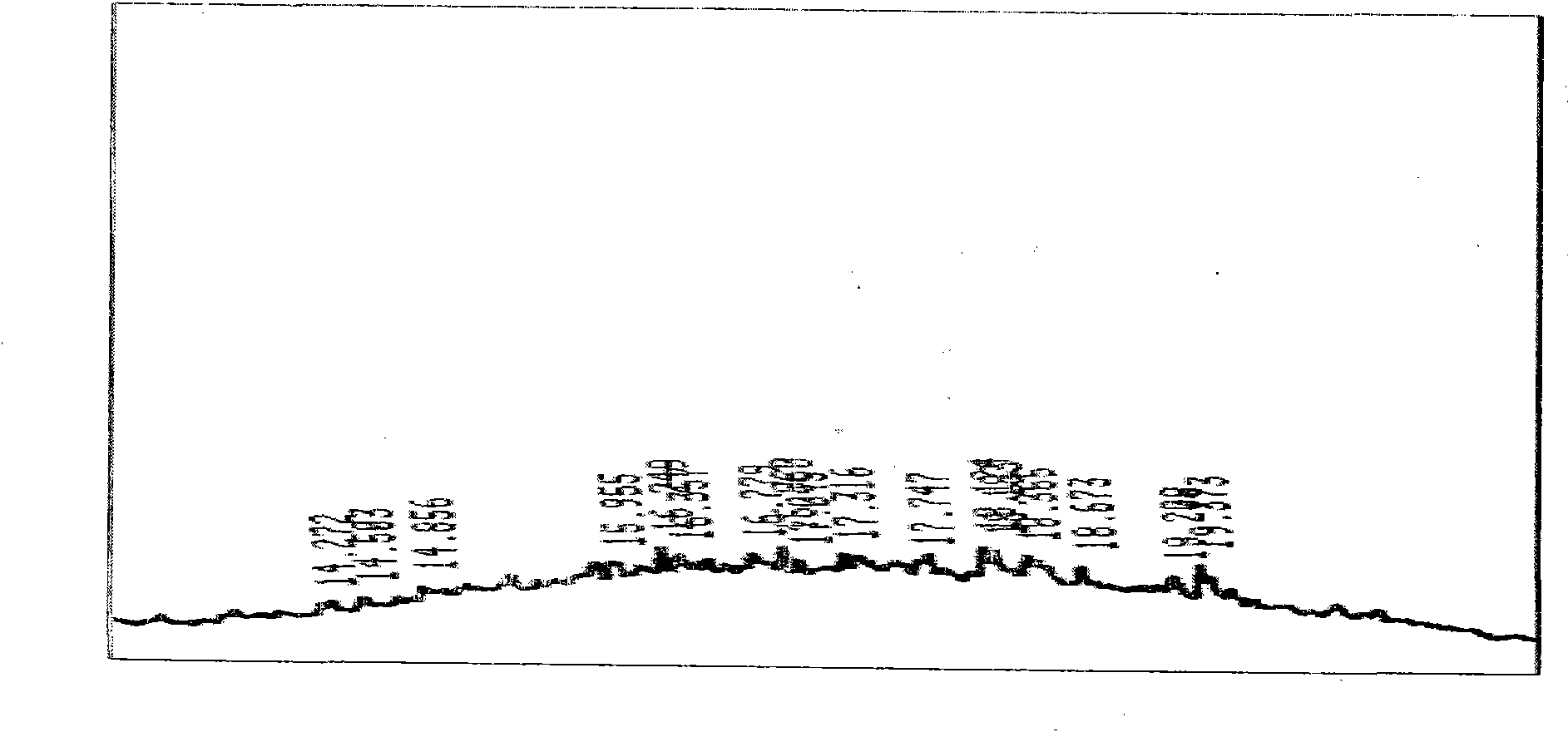

[0032] The mensuration of the emulsification rate of preparation bio-type oil spill dispersant in embodiment 2 (environmental temperature is controlled at 20-25 ℃ during the test)

[0033] 1. Dissolve 30 grams of commercially available coarse sea salt in 1 liter of distilled water, filter and complete the preparation of artificial sea water;

[0034] 2. Use a 50ml graduated cylinder to add 50ml of artificial seawater to the 100ml separatory funnel, and put the plastic oil limiting ring on the water surface.

[0035] 3. Extract 1 gram of standard oil (Shengli crude oil topped at 100°C) with a 1 ml syringe, squeeze it into the plastic oil limiting ring in the separatory funnel after taring on the electronic balance, and use a 1 ml syringe with a needle Take 0.2 g of biological oil spill dispersant, and evenly drop the calculated amount of oil spill dispersant to the oil surface in the plastic oil limiting ring after taring on the electronic balance.

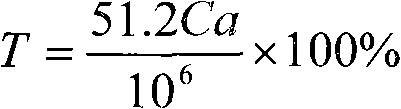

[0036] 4. After oscillatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com