Cadmium telluride quantum dot grafted graphene-carbon nanotube composite thin film optical switch material and preparation thereof

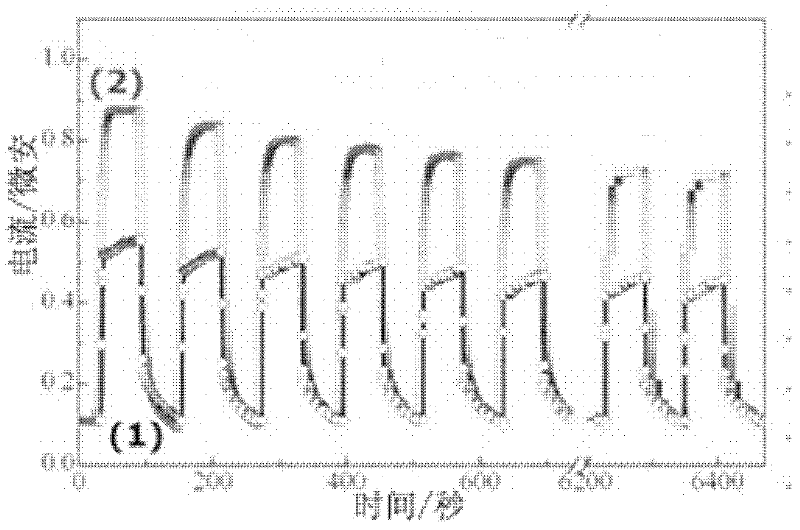

A carbon nanotube composite, cadmium telluride quantum dot technology, applied in nano-optics, nanotechnology, nanotechnology and other directions, can solve the problem of nano-semiconductor quantum dots grafted graphene-carbon nanotube composite thin film optical switch material Light control and its optical and electrical properties, etc., to achieve the effects of fast light response performance, stable properties, and high photoelectric conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (2) Preparation of carbon nanotube solution

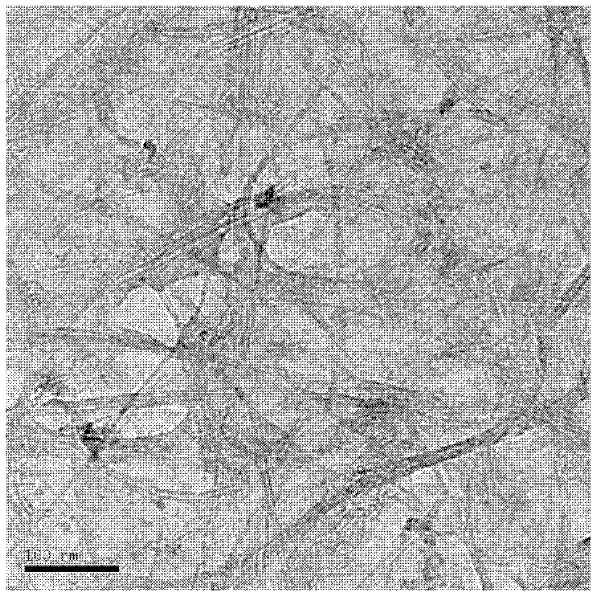

[0032] The carbon nanotubes were passed through a vacuum tube furnace at 550 ° C with a volume ratio of air to nitrogen of 1:4 and a total gas flow rate of 300 cm 3 / min mixed gas atmosphere for 1 hour, then condensed and refluxed in a hydrochloric acid solution with a mass concentration of 37% at 100°C for 1 hour, then suction filtered, and repeatedly washed the filter cake with deionized water until the washing liquid was neutral. Vacuum-dry at 60°C to obtain pure carbon nanotubes, then add pure carbon nanotubes and surfactant sodium dodecyl sulfate into deionized water, and disperse ultrasonically to form carbon nanotubes at a concentration of 0.05mg / mL , Surfactant mass concentration concentration is 0.5% solution, recorded as A solution.

[0033] (3) Graphene oxide was ultrasonically dispersed in deionized water to prepare a graphene oxide solution with a concentration of 0.5 mg / mL, which was designated as B solution. ...

Embodiment 2

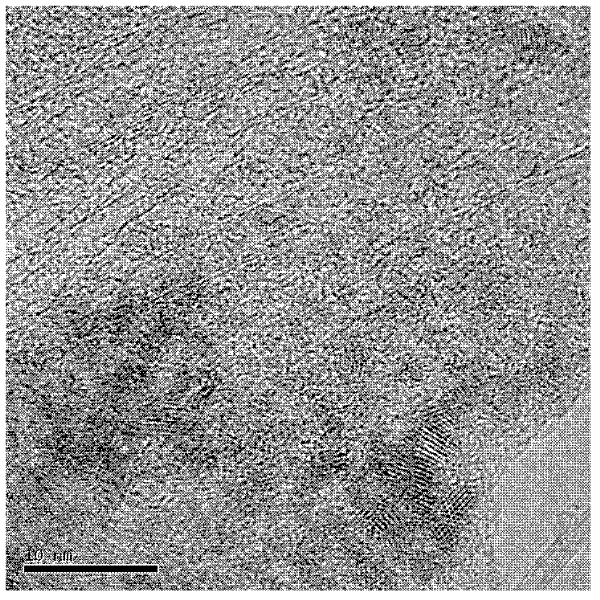

[0046] (7) Prepare a sodium chloride solution with a concentration of 20mmol / L, and dilute a polydipropylene dimethyl ammonium chloride solution with a mass concentration of 30% into the sodium chloride solution to obtain polydipropylene dimethyl ammonium chloride A solution with an ammonium chloride concentration of 1 mg / mL is recorded as solution C and placed in a small beaker for later use.

[0047] (8) Prepare a sodium hydroxide solution with a pH of 11, dilute the cadmium telluride quantum dots into the sodium hydroxide solution with a pH of 11, and ultrasonicate at a low power for 5 minutes to make the cadmium telluride quantum dots in the sodium hydroxide solution with a pH of 11 Evenly dispersed in the solution, the obtained cadmium telluride quantum dot dilution is recorded as D solution, placed in a small beaker and stored away from light, for future use.

[0048] (9) Soak the dried graphene-carbon nanotube composite film prepared in step (5) in the C solution prepar...

Embodiment 3

[0052] (7) Prepare a sodium chloride solution with a concentration of 50mmol / L, and dilute a polydipropylene dimethyl ammonium chloride solution with a mass concentration of 30% into the sodium chloride solution to obtain polydipropylene dimethyl ammonium chloride A solution with an ammonium chloride concentration of 1 mg / mL is recorded as solution C and placed in a small beaker for later use.

[0053] (8) Prepare a sodium hydroxide solution with a pH of 11, dilute the cadmium telluride quantum dots into the sodium hydroxide solution with a pH of 11, and ultrasonicate at a low power for 5 minutes to make the cadmium telluride quantum dots in the sodium hydroxide solution with a pH of 11 Evenly dispersed in the solution, the obtained cadmium telluride quantum dot dilution is recorded as D solution, placed in a small beaker and stored away from light, for future use.

[0054] (9) Soak the dried graphene-carbon nanotube composite film prepared in step (5) in the C solution prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com