Defect-sensitized lithium ferrous phosphate cathode material and preparation method thereof

A technology for sensitizing lithium iron phosphate and cathode materials, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as ion mixing, and achieve the effect of complete structure, uniform grains, and broad market application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

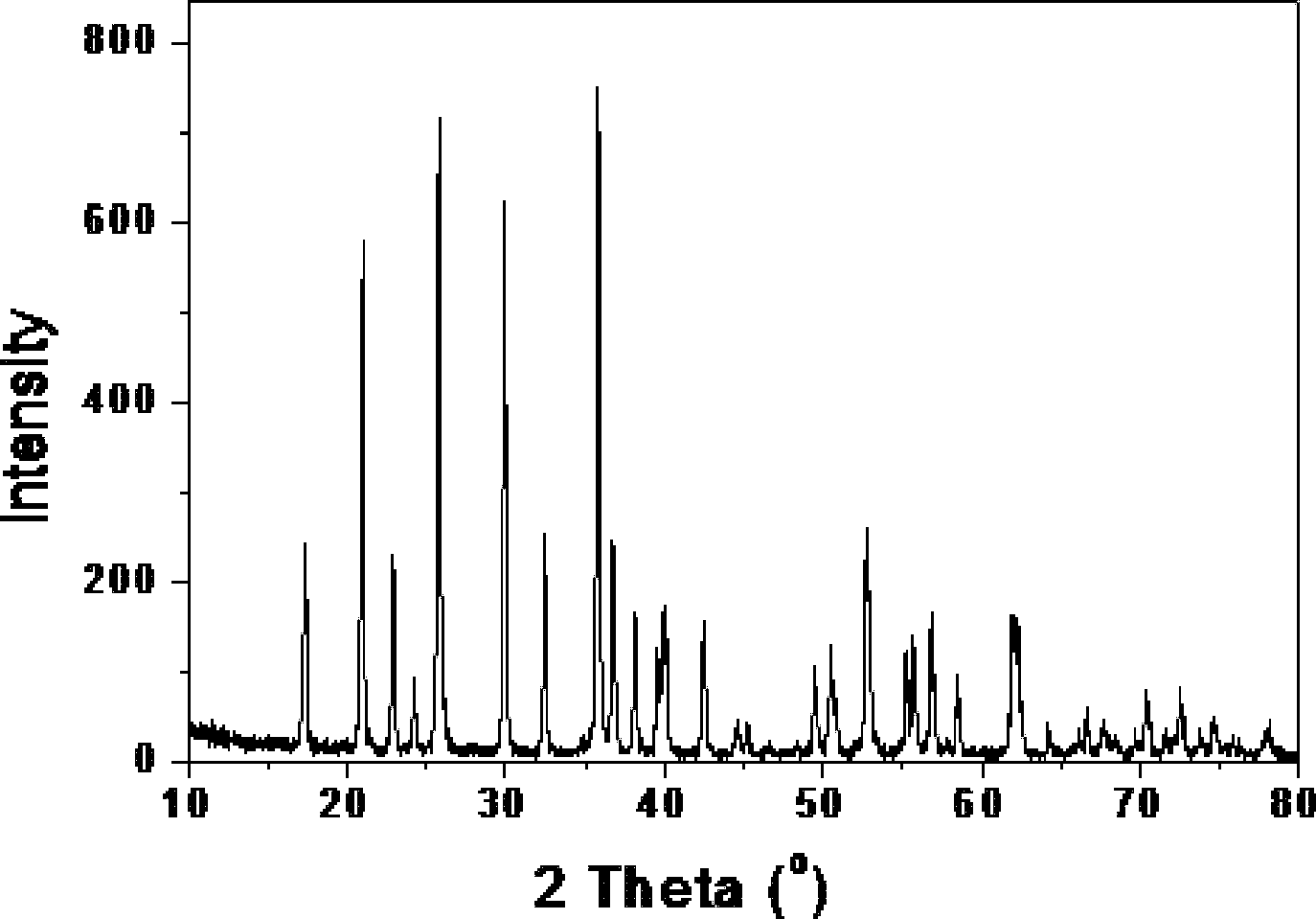

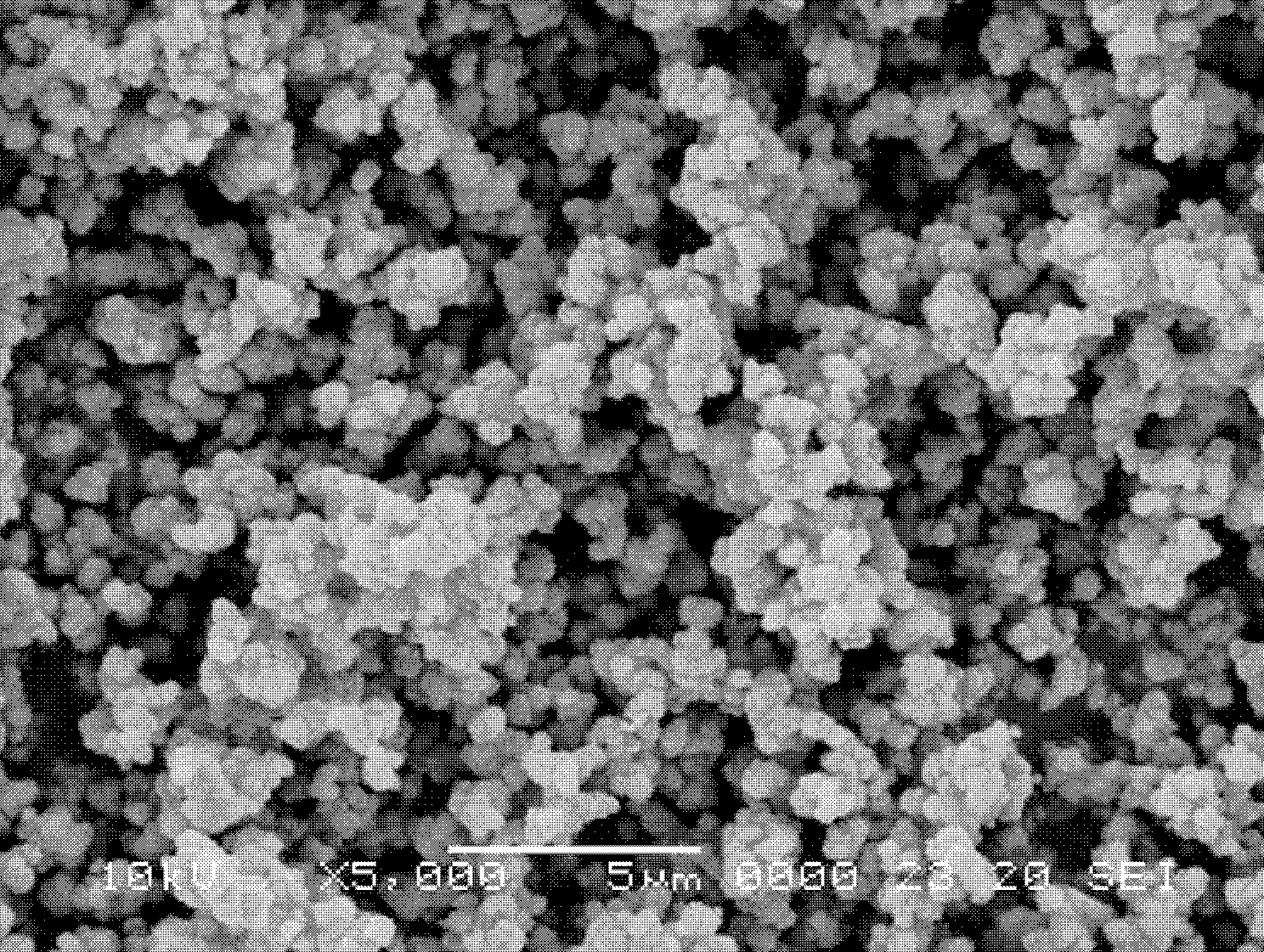

Embodiment 1

[0029] Mix lithium carbonate, aluminum nitrate, ferrous oxalate, and ammonium dihydrogen phosphate in a molar ratio of 0.97:0.02:0.98:1, and then dissolve oxalic acid, which accounts for 18% of the total mass of other salts, in ethanol and add it into it for mechanical mixing. 0.5 hours; after drying, put it into a vacuum tube furnace, decompose at 500 degrees Celsius for 3 hours in a high-purity nitrogen atmosphere, and crystallize at 900 degrees Celsius for 7 hours. The obtained material was analyzed by X-ray diffraction as olivine structure, space group Pnmb, confirmed as sample 1 (sample-1): Li 0.97 Al 0.02 Fe 0.98 PO 4 / C defect-sensitized material.

Embodiment 2

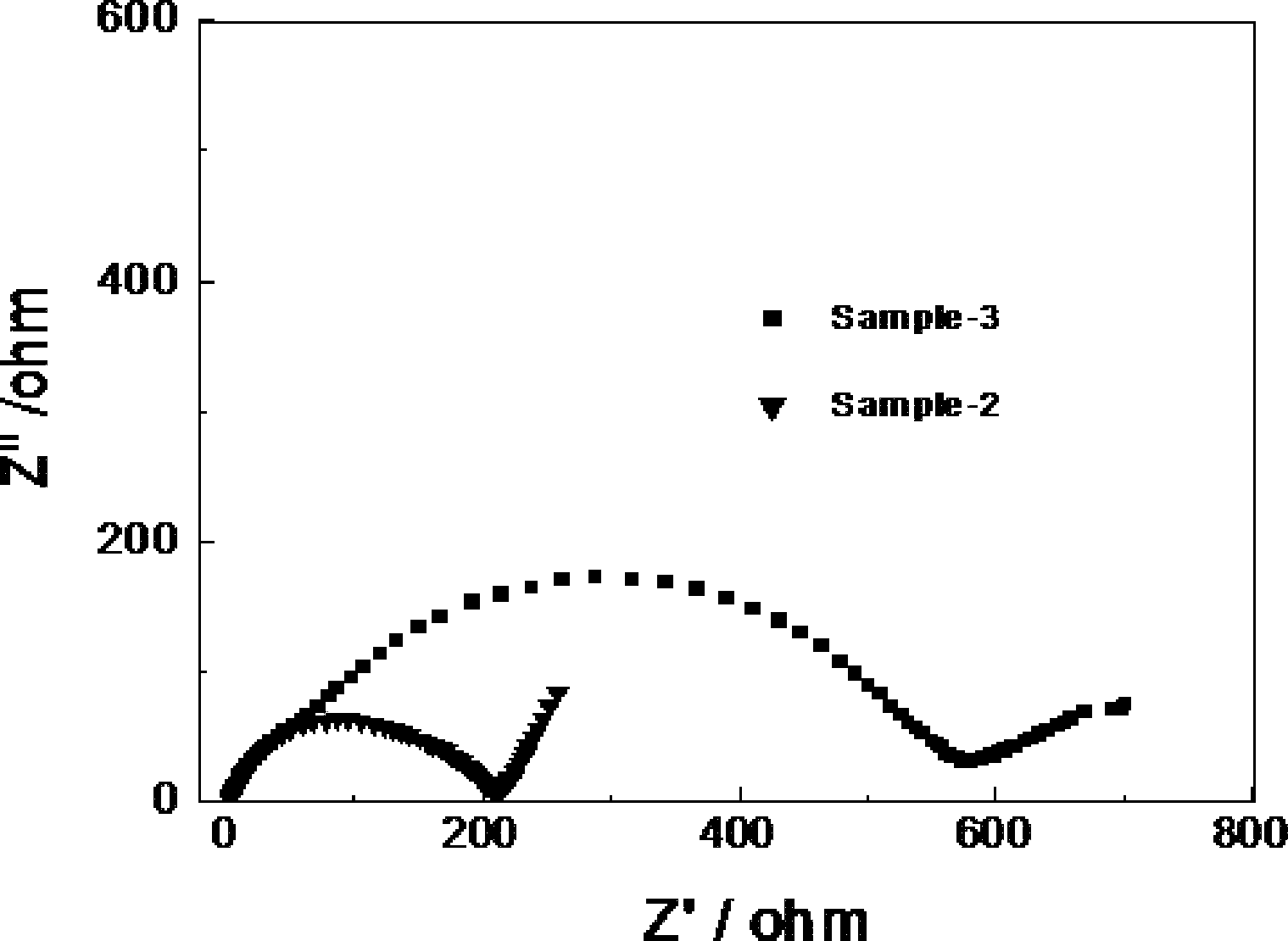

[0031] Lithium hydroxide, zirconium nitrate, ferrous sulfate, and diammonium hydrogen phosphate are mixed uniformly in a molar ratio of 0.96:0.01:0.99:1, and then 15% of the total mass of other salts is dissolved in ethanol and added to the machine Mix and grind for 0.5 hours; after drying, put it into a vacuum tube furnace, decompose at 400 degrees Celsius for 4 hours in a high-purity argon atmosphere, and then crystallize at 700 degrees Celsius for 12 hours. The obtained material was analyzed by X-ray diffraction as olivine structure, space group Pnmb, confirmed as sample-2 (sample-2): Li 0.96 Zr 0.01 Fe 0.99 PO 4 / C defect-sensitized material. The resulting product was assembled into a button battery, and its AC impedance spectrum was tested at a voltage of 3.45V.

Embodiment 3

[0033] Lithium hydroxide, ferrous acetate, and diammonium hydrogen phosphate were mixed uniformly in a molar ratio of 1:1:1, and then 20% of the total mass of other salts was dissolved in citric acid in propanol and mechanically mixed for 0.5 Hours; after drying, put it into a vacuum tube furnace, decompose and treat it at 300 degrees Celsius for 5 hours in a high-purity nitrogen atmosphere, and then crystallize it at 500 degrees Celsius for 20 hours. The obtained material was analyzed by X-ray diffraction as olivine structure, space group Pnmb, confirmed as sample 3 (sample-3): LiFePO 4 / C Defect-free sensitized material. The resulting product was assembled into a button battery, and its AC impedance spectrum was tested at a voltage of 3.45V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com