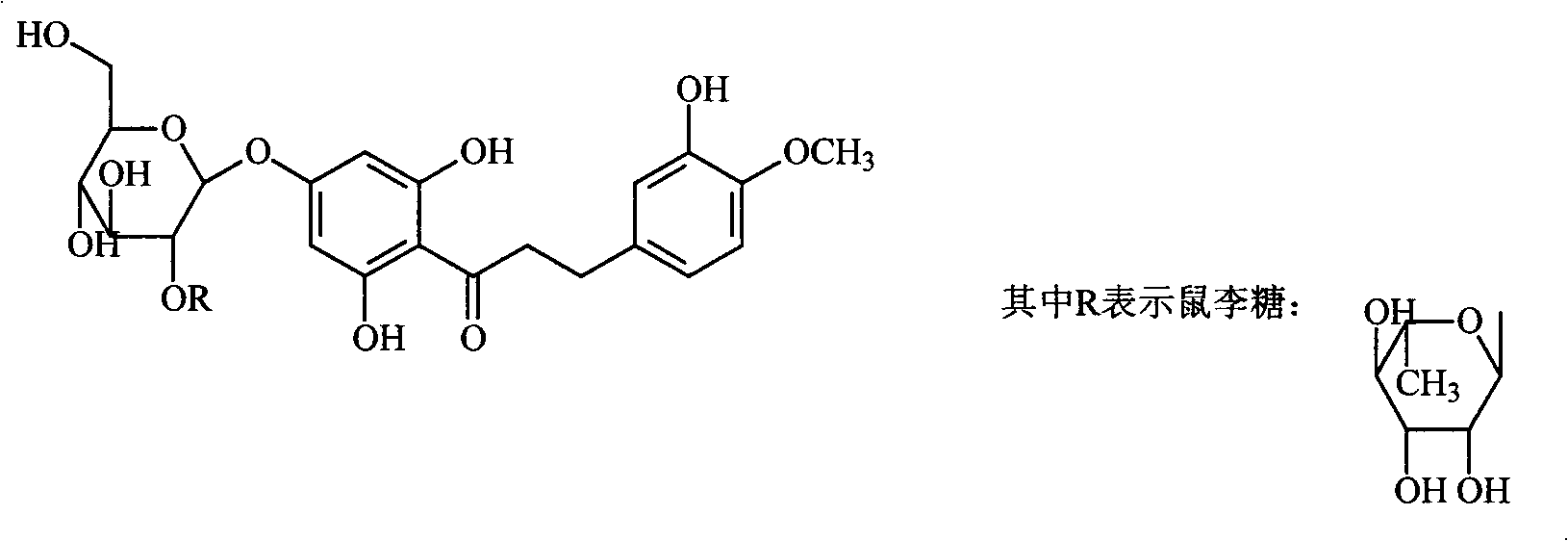

Preparation method of neohesperidin dihydrochalcone

A technology of hesperidin dihydrochalcone and neohesperidin, applied in the field of hydrogenation to prepare neohesperidin dihydrochalcone, which can solve unfavorable industrial production, low yield of finished products, high risk, etc. problems, to achieve the effect of facilitating industrial production, high yield of finished products, and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The operation method for preparing neohesperidin dihydrochalcone in this embodiment is carried out according to the following two steps: preparation of crude neohesperidin dihydrochalcone: dissolve 9 g of potassium hydroxide or sodium hydroxide under stirring Pour 150ml of tap water into a 2000ml round-bottomed flask, then add 30g of neohesperidin into the lye under stirring conditions, stir and dissolve, add 1.5g of Raney nickel, start stirring, under 0.01-0.02MPa hydrogen pressure Carry out the hydrogenation reaction and react for 5 hours. After the reaction, adjust the pH of the reaction solution to between 7.2 and 7.2 with hydrochloric acid, and a large amount of yellow solids will be precipitated. After standing for 26 hours, the crystalline solids will be filtered out to obtain neohesperidin dihydrogen Crude chalcone.

[0028] Preparation of the finished product of neohesperidin dihydrochalcone: heat and dissolve the crude product of neohesperidin dihydrochalcone ...

Embodiment 2

[0030] The operation method for preparing neohesperidin dihydrochalcone in this embodiment is carried out according to the following two steps: the preparation of the crude product of neohesperidin dihydrochalcone: 1.5kg potassium hydroxide or sodium hydroxide is stirred Dissolve it in 25kg tap water and pour it into the hydrogenation reaction kettle, then add 5kg neohesperidin into the lye under stirring condition, after stirring and dissolving, add 0.3kg new Raney nickel, start stirring, under 0.01-0.02MPa hydrogen pressure Carry out the hydrogenation reaction and react for 5.5 hours. After the reaction, adjust the pH of the reaction solution to between 7.5 and 7.5 with hydrochloric acid, and a large amount of yellow solids will precipitate out. After standing for 26 hours, filter out the crystalline solids to obtain neohesperidin dihydrogen Crude chalcone.

[0031] Preparation of finished product of neohesperidin dihydrochalcone: heat and dissolve the crude product of neohe...

Embodiment 3

[0033] The operation method for preparing neohesperidin dihydrochalcone in this embodiment is carried out according to the following two steps: preparation of crude product of neohesperidin dihydrochalcone: dissolve 15 kg of potassium hydroxide or sodium hydroxide under stirring Pour 300kg of tap water into the hydrogenation reactor, then add 50kg of neohesperidin into the lye with stirring, after stirring and dissolving, add 3.0kg of new Raney nickel, start stirring, and carry out under 0.01-0.02MPa hydrogen pressure Hydrogenation reaction, reaction for 6.0 hours, after the reaction, adjust the pH of the reaction solution to between 7 and 7 with hydrochloric acid, a large amount of yellow solids will precipitate out, and after standing for 25 hours, filter out the crystalline solids to obtain neohesperidin dihydrochalcone Crude.

[0034] Preparation of the finished product of neohesperidin dihydrochalcone: heat and dissolve the crude product of neohesperidin dihydrochalcone w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com