Preparation method for high water-holding capacity and water-insolubility corn dietary fiber

A water-insoluble, dietary fiber technology, applied in the fields of food preparation, food science, application, etc., can solve the problems of low water-holding capacity of water-insoluble dietary fiber and insufficient physiological effect, and achieves low cost, convenient operation, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

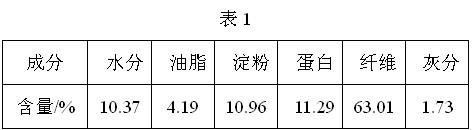

[0038] a: Preparation of non-water-soluble corn fiber

[0039] Firstly, the corn seed coats are screened, washed and dried. Use a pulverizer to pulverize and pass through a 100-mesh sieve. The fat content of corn husks is only about 4%, and the fat is removed by soaking in 6# solvent oil to obtain degreased corn husk powder and dried; the dried degreased corn husk powder and water are in a mass ratio of 1:10 Mix and stir to make a slurry, adjust pH=7.5 with dilute alkali; then add 1398 neutral protease, the enzyme amount is 2000u / gDS, enzymolyze at 45°C for 60min, then adjust pH=6 with dilute hydrochloric acid, add 0.2% (w / wDS) high-temperature-resistant a-amylase, hydrolyze at 100°C for 60 minutes, then cool down to 60°C to inactivate the enzyme to obtain a two-step enzymatic hydrolysis slurry; filter the enzymatic hydrolysis slurry, and add water to the obtained solid to make a slurry to adjust the slurry pH = 6.5 and add 0.1% (w / wDS) glucoamylase, continue hydrolysis at 5...

Embodiment 2

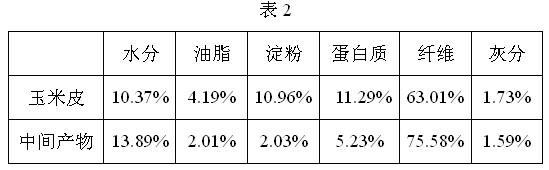

[0049] Take 100 g of corn seed coat powder that has been screened, dried and crushed through a 100-mesh sieve, dissolved in 900 mL of 6# solvent oil, soaked at room temperature for 5 hours, filtered to recover the solvent, and dried to obtain degreased corn hull powder; Add defatted corn husk powder into 1500mL water and make a slurry, adjust pH=7.5 with dilute sodium hydroxide solution, add 1398 neutral protease 300000u, enzymolyze at 45°C for 70min and inactivate the enzyme activity; then adjust pH with dilute hydrochloric acid =6.2, add 0.05g of high temperature resistant a-amylase, hydrolyze in boiling water bath for 80min; then cool down to 58℃, adjust pH=5.5, add 0.03g of glucoamylase, keep 58℃ for 180min, then heat to 95℃ The enzymatic activity was inactivated for 15 minutes to obtain a two-step enzymatic hydrolysis slurry. After cooling down, the enzymatic hydrolysis slurry was filtered, and the filter cake was washed with water and dried to obtain 91.3 g of intermediat...

Embodiment 3

[0052] Take 80g of corn seed coat powder that has been screened, dried and crushed through a 150-mesh sieve, dissolved in 1000mL6# solvent oil, soaked at room temperature for 4h, filtered to recover the solvent, and dried to obtain degreased corn hull powder; Add fat corn bran powder into 1300mL water and make a slurry, adjust pH=7.3 with dilute sodium hydroxide solution, add 1398 neutral protease 300000u, enzymolyze at 46°C for 90min and inactivate the enzyme activity, then adjust pH=7.3 with dilute hydrochloric acid After 6.1, add 0.05g of high temperature resistant a-amylase, hydrolyze in boiling water bath for 100min; then cool down to 56℃, add 0.02g of glucoamylase and adjust pH=5.8, keep 56℃ for 200min, then heat to 95℃ Inactivate the enzyme for 20 minutes to obtain the enzymatic slurry, lower the temperature, then filter the enzymatic slurry, wash the filter cake with water and filter to obtain a wet solid;

[0053] Disperse the above wet solid in water and stir to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com