Chlorinated hydrocarbon-polluted underground water blowing oxidation and tail gas treatment process

A technology for tail gas treatment and chlorinated hydrocarbons, which is applied in the field of remediation of chlorinated hydrocarbons polluted groundwater, can solve the problems of device flexibility, poor operability, serious secondary pollution, incomplete treatment, etc. The effect of high, saving investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

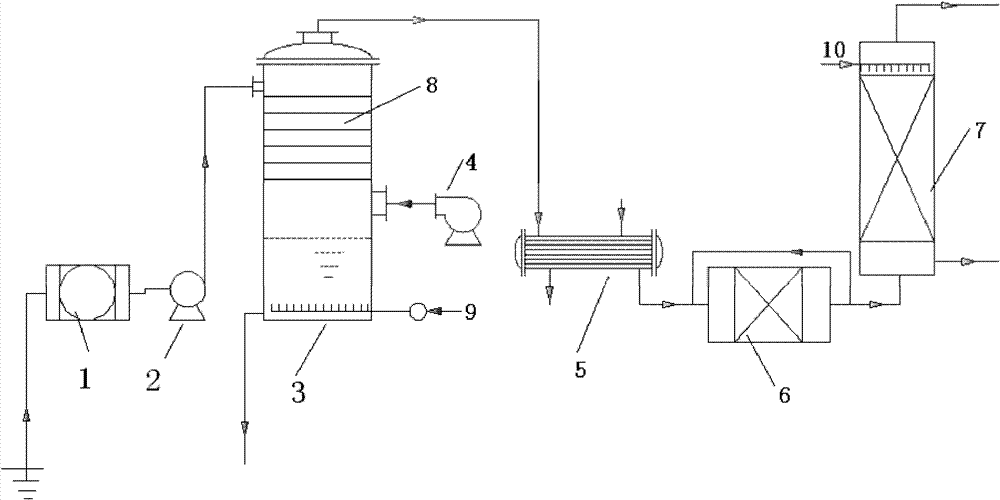

[0027] Please see attached figure 1 , chlorinated hydrocarbon polluted groundwater blowing off oxidation and tail gas treatment process, the specific steps are: pump out ground water, after filtering out impurities, use air blowing off method to blow out volatile chlorinated aliphatic hydrocarbons in water to decolorize colored organic matter ozone; blow off tail gas Containing high concentration of chlorinated hydrocarbons, catalytic combustion, the water vapor in the tail gas should be partially condensed before combustion; the hydrogen chloride produced in the tail gas after combustion is chemically neutralized and absorbed.

[0028] The equipment used in the deoxidation and tail gas treatment process of chlorinated hydrocarbon polluted groundwater includes multi-functional countercurrent deoxidation combined tower, shell and tube heat exchanger, volatile chlorinated hydrocarbon catalytic combustion device and hydrogen chloride tail gas neutralization absorption tower, etc. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com