Supported metal doped mesoporous titanium dioxide photocatalyst and application thereof

A technology of mesoporous titanium dioxide and metal doping, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of weak visible light response and insufficient photocatalytic activity , Restricting practical application and other issues, to achieve the effect of not harsh process conditions, high photocatalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, first mix and dissolve 20ml of absolute ethanol and 0.4g of PEG2000, then add 6ml of tetrabutyl titanate (0.017mol) 6ml, add catalyst carrier nano-silica (Cabot, A-300) 1.2 g, after stirring for 30 minutes; add 5ml of deionized water, then add 5ml of glacial acetic acid, control the pH value to 2-3; then drop 5ml of 0.01mol / L ferric nitrate aqueous solution, continue to stir for 120min to form a sol, the sol is placed in a water bath The gelation reaction was carried out at 65°C, the surface solvent disappeared after 6 hours, and the system transformed into a light yellow wet gel, then baked at 80°C for 24 hours, then ground into powder, and calcined at 550°C for 2 hours in an air atmosphere to obtain 2.0g of loaded iron-doped mesoporous titanium dioxide photocatalyst.

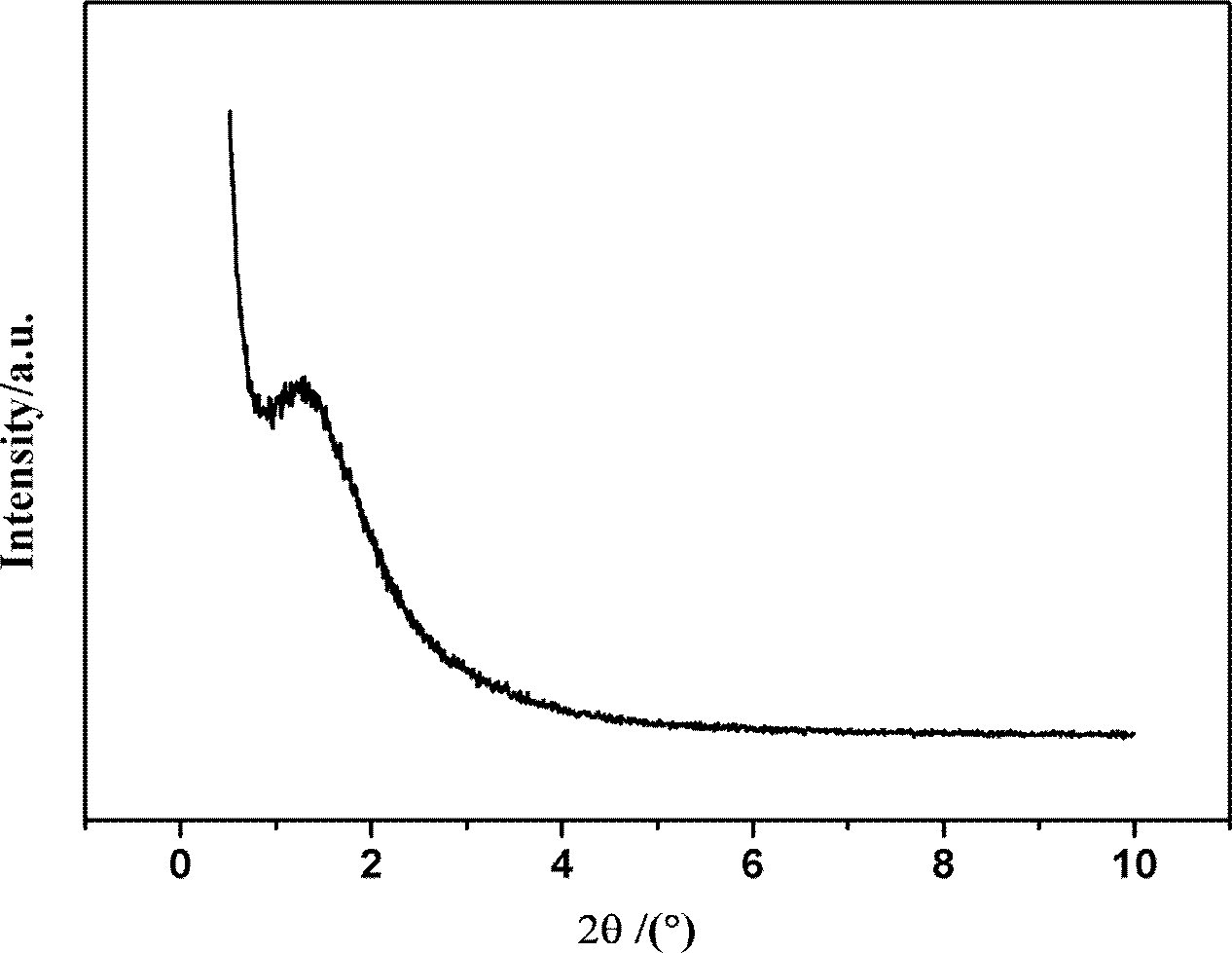

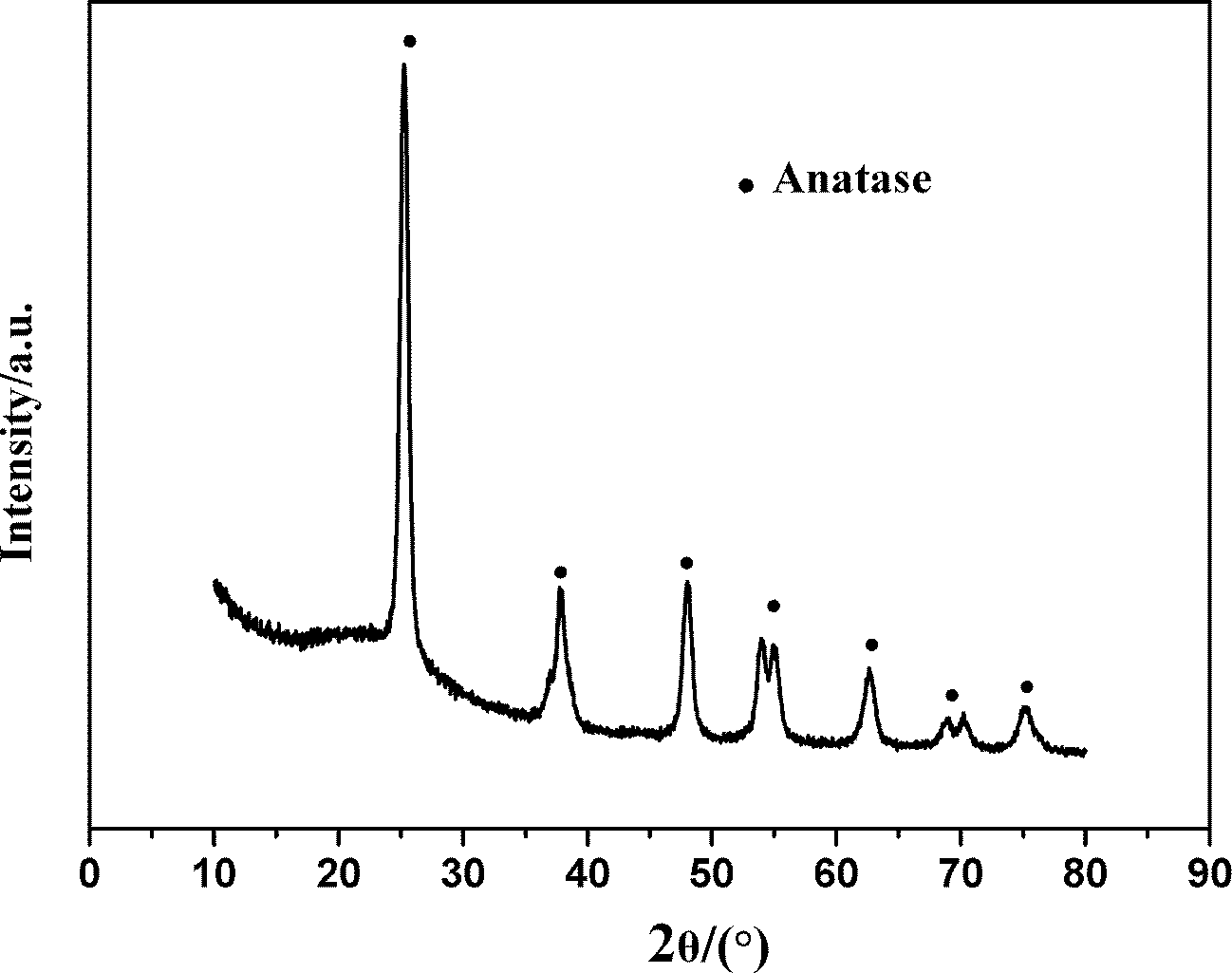

[0033] Gained product carries out XRD test, test condition: small-angle XRD diffraction is measured on the X'Pert PRO type X-ray diffractometer that Holland PNAlytical Company produ...

Embodiment 2

[0037]At room temperature, first mix and dissolve 20ml of absolute ethanol and 0.4g of PEG4000, then add 6ml (0.017mol) of tetrabutyl titanate, and add 1.2g of catalyst carrier nano-silica (Cabot, A-300) under vigorous stirring, After stirring for 30 minutes, add 5ml of deionized water, then add 5ml of glacial acetic acid, and control the pH value to 2-3; then add 5ml of 0.01mol / L lanthanum nitrate aqueous solution dropwise, and continue stirring for 120min to form a sol, which is kept in a water bath for 70 The gelation reaction is carried out under the condition of ℃, the surface solvent disappears after 6 hours, and the system turns into a white wet gel, and then it is baked at 80℃ for 24 hours and then ground into powder, and calcined at 550℃ for 2 hours in the air atmosphere to obtain the loaded lanthanum doped gel. 2.1g of heteromesoporous titanium dioxide photocatalyst.

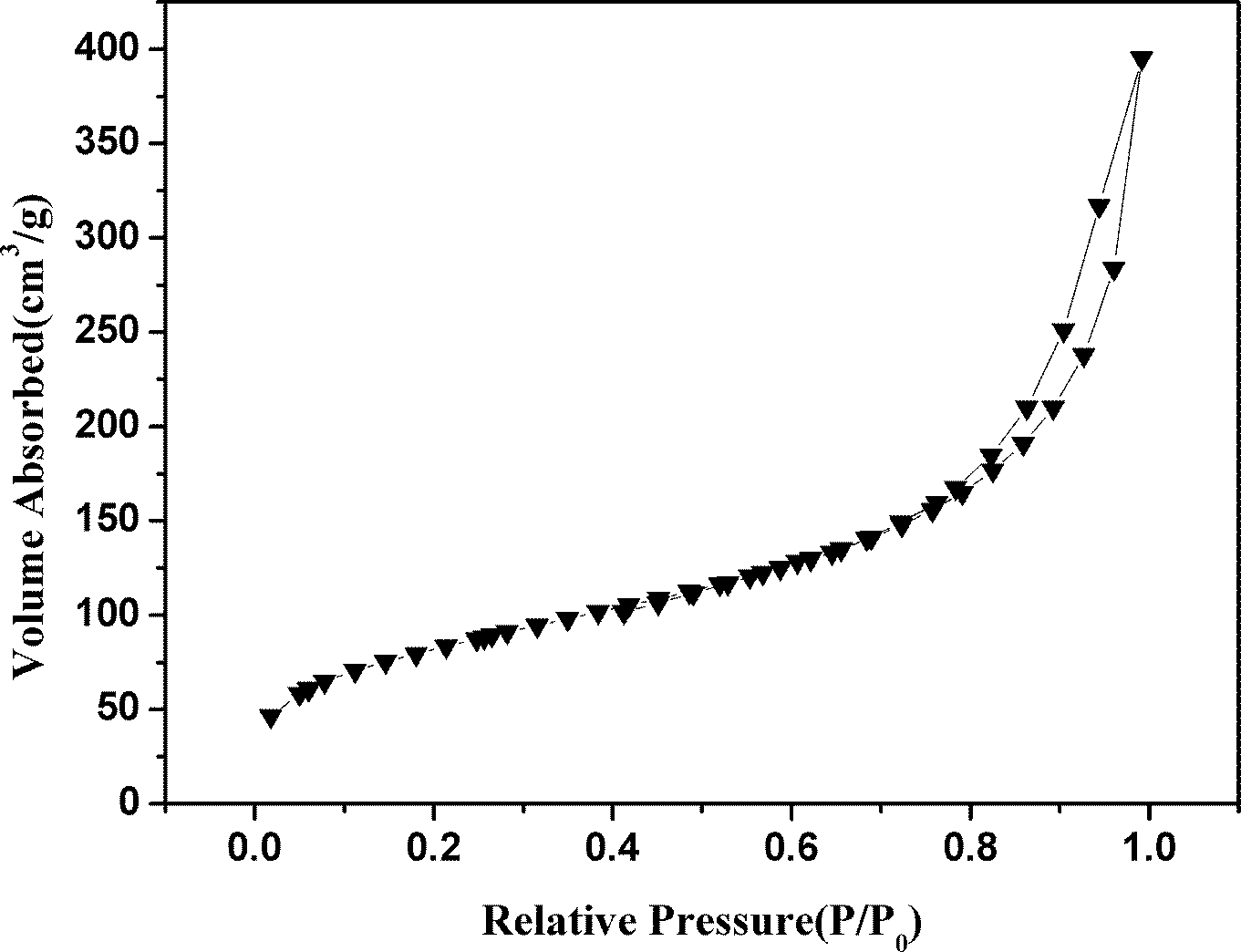

[0038] The resulting product was subjected to N 2 Adsorption-desorption test, test condition: N 2...

Embodiment 3

[0040] At room temperature, first mix and dissolve 20ml of absolute ethanol and 0.3g of PEG6000, then add 6ml (0.020mol) of isopropyl titanate, and add 1.2g of catalyst carrier nano-silica (Cabot, A-300) under vigorous stirring , after stirring for 60 minutes; add 5ml of deionized water, then add 5ml of glacial acetic acid, control the pH value to 2-3; then drop in 0.01mol / L praseodymium nitrate aqueous solution 3ml, continue to stir for 180min to form a sol, the sol is in a water bath Carry out gelation reaction at 65°C, the surface solvent disappears after 6 hours, and the system turns into a white wet gel, then bake at 80°C for 24 hours, grind it into powder, and calcinate at 600°C for 2 hours in an air atmosphere to obtain loaded praseodymium Doped mesoporous titanium dioxide photocatalyst 2.3g.

[0041] The obtained product was subjected to Uv-Vis test, and the test conditions were measured by a SHIMADZUUV-2550 UV-vis spectrophotometer produced in Japan, the wavelength ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com