High-efficiency crystalline silicon cell with next-generation structure and manufacturing method for high-efficiency crystalline silicon cell

A technology of crystalline silicon cells and production methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as restricting the improvement of cell efficiency, and achieve the effects of improving efficiency, reducing resistance, and getting rid of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

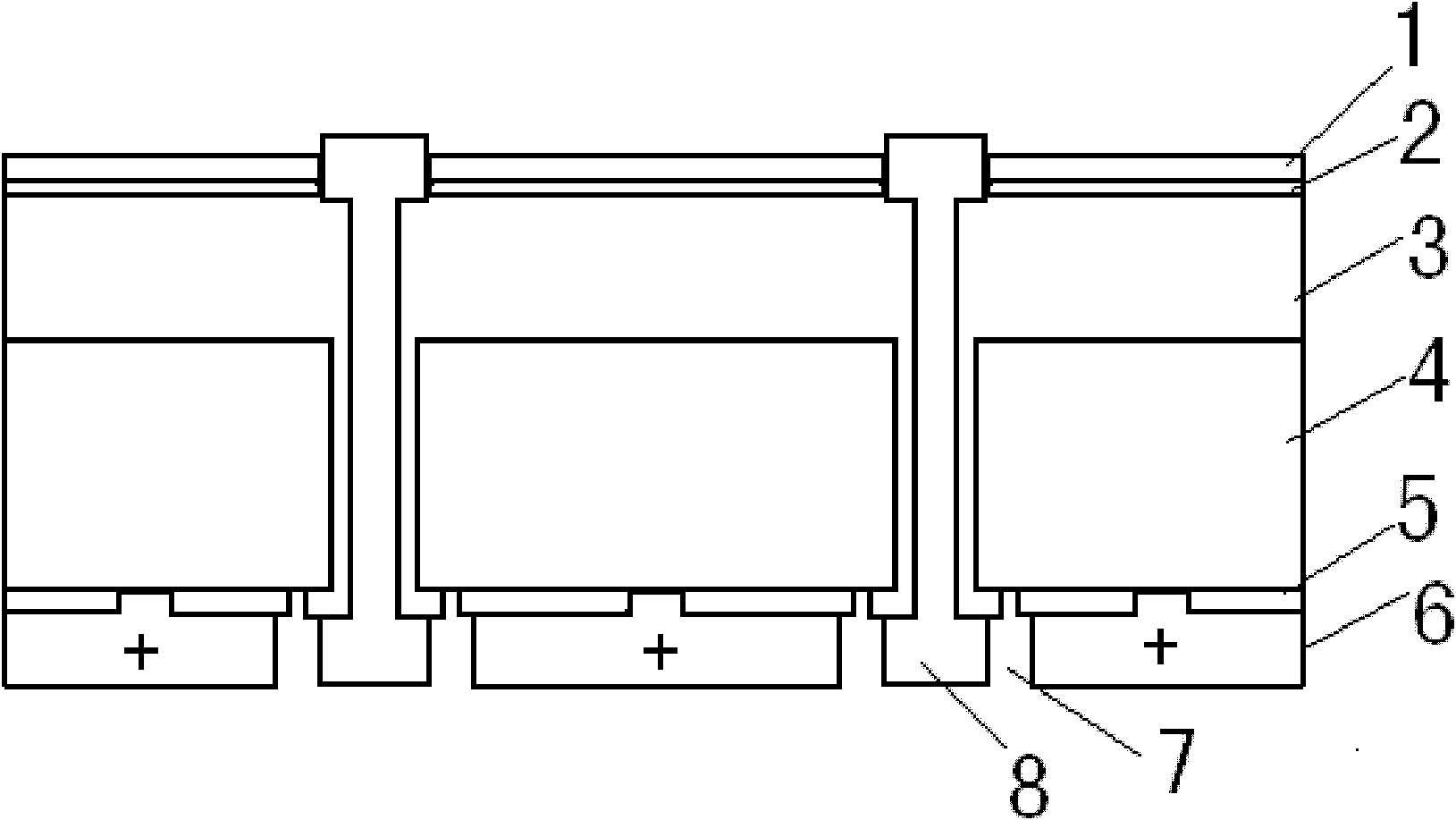

[0031] Embodiment 1: as figure 1 , 2 shown;

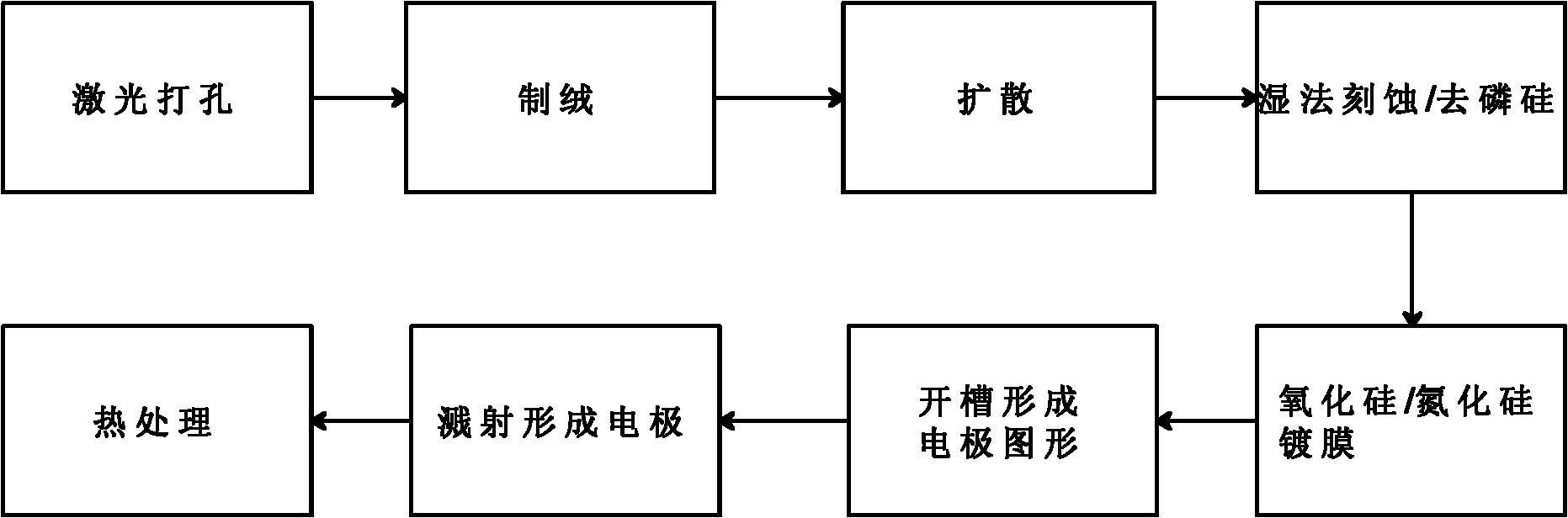

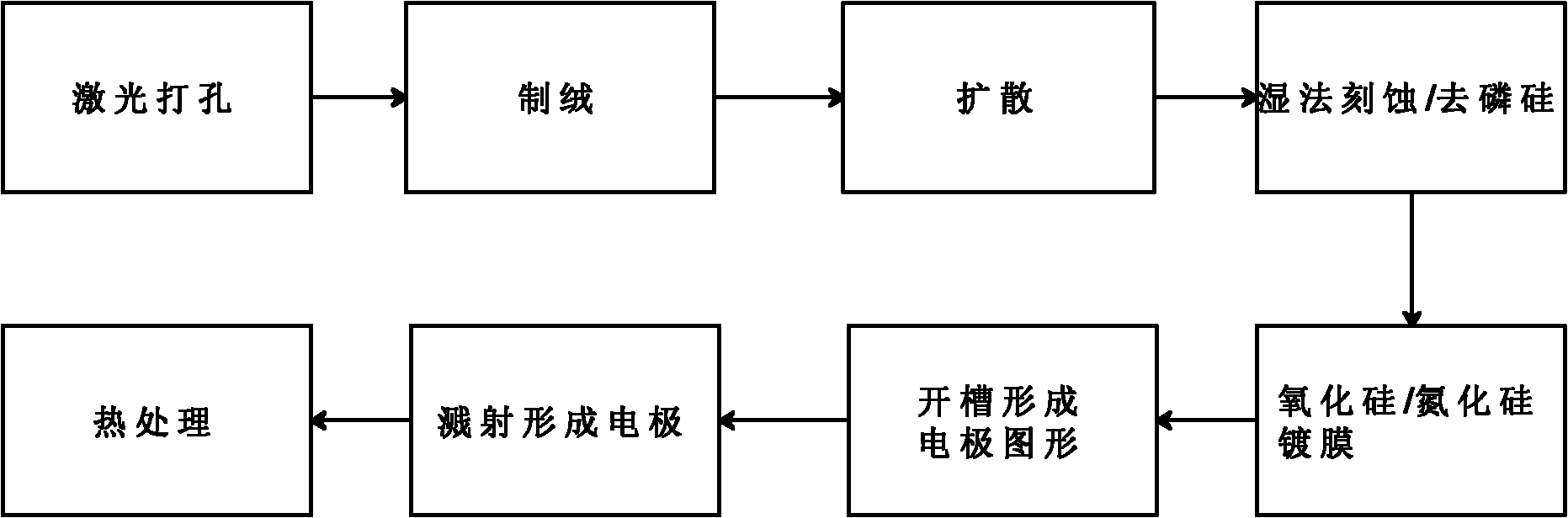

[0032] A method for manufacturing high-efficiency crystalline silicon solar cells, adding silicon oxide and aluminum oxide passivation steps, MWT technology steps, and new grid line forming steps on the basis of conventional processes; including the following steps;

[0033] In the laser drilling step, a laser is used to form 4*4 round holes with a diameter of about 300 microns on the surface of the 156mm*156mm polysilicon wafer, penetrating the silicon wafer;

[0034] Texturing step, using HNO3 / HF / H2O system (nitric acid / hydrofluoric acid / water system), nitric acid is electronically pure, with a mass concentration of about 69%; hydrofluoric acid is electronically pure, with a mass concentration of about 49%; water is deionized Water, the resistance value is about 18 megohm cm; the volume ratio of the three is about 6.5:1:3; the temperature is 8-11°C. Clean the surface of the silicon wafer and form a suede surface;

[0035] In ...

Embodiment 2

[0041] Embodiment 2: as figure 1 , 2 shown;

[0042] A method for manufacturing high-efficiency crystalline silicon solar cells, adding silicon oxide and aluminum oxide passivation steps, MWT technology steps, and new grid line forming steps on the basis of conventional processes; including the following steps;

[0043] In the laser drilling step, a laser is used to form 4*4 round holes with a diameter of about 250 microns on the surface of the 156mm*156mm single / polycrystalline silicon wafer, which penetrate the silicon wafer;

[0044] Or: laser drilling step, using a laser to form 3*3 9 round holes with a diameter of about 250 microns on the surface of the 125mm*125mm single / polycrystalline silicon wafer, penetrating the silicon wafer;

[0045] In the texturing step, polycrystalline use HNO3 / HF / H2O (nitric acid / hydrofluoric acid / water) system to clean the surface of the silicon wafer and form a textured surface; single crystal uses NaOH / IPA / H2O (sodium hydroxide / isopropano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com