Preparation method of manganese lithium borate anode material cladded by carbon nano tubes of lithium ion battery

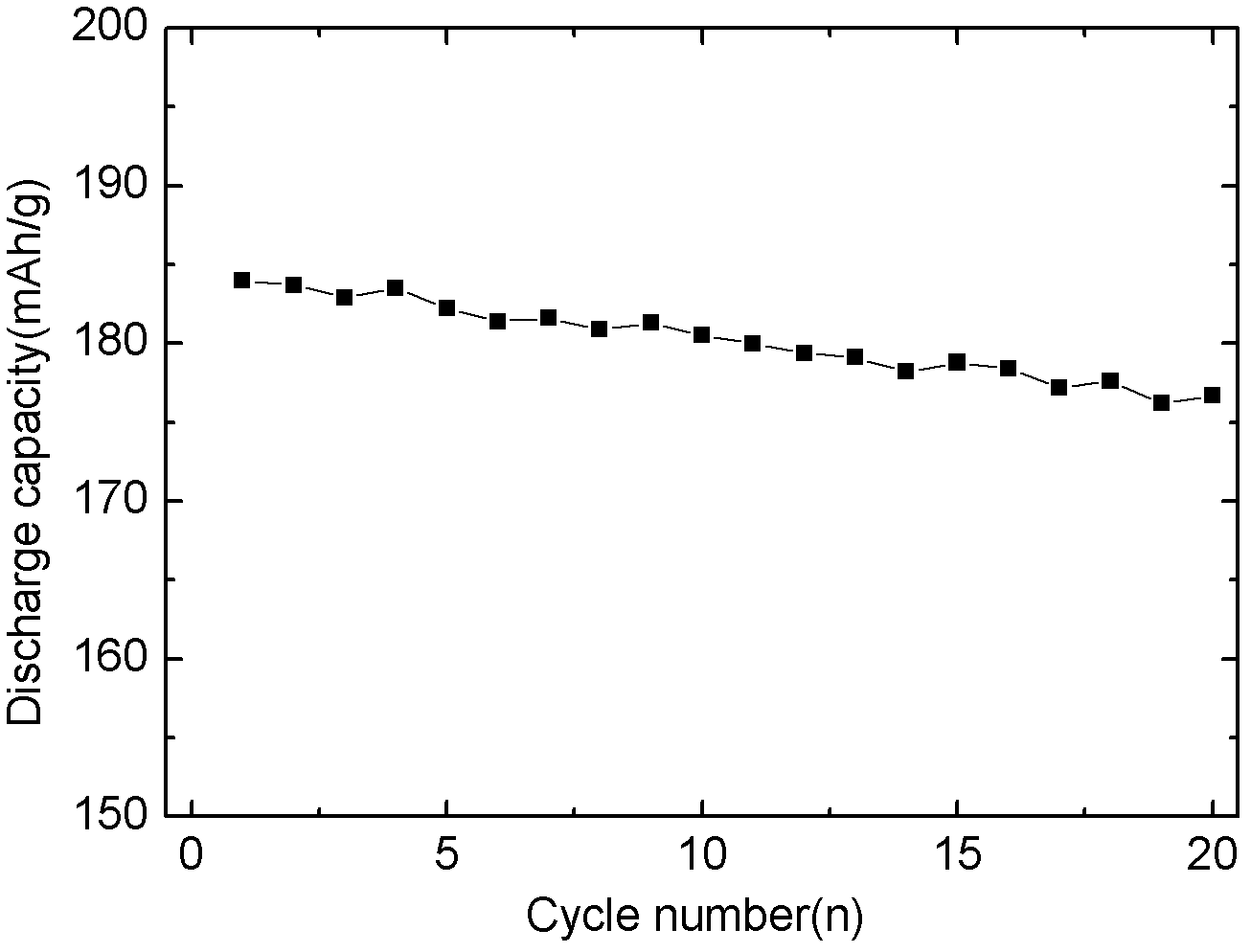

A technology of lithium-ion batteries and carbon nanotubes, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as complex and changeable processes, poor electrochemical performance, and unevenness, so as to achieve good technical controllability and reduce practical costs. Effects of cost, good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

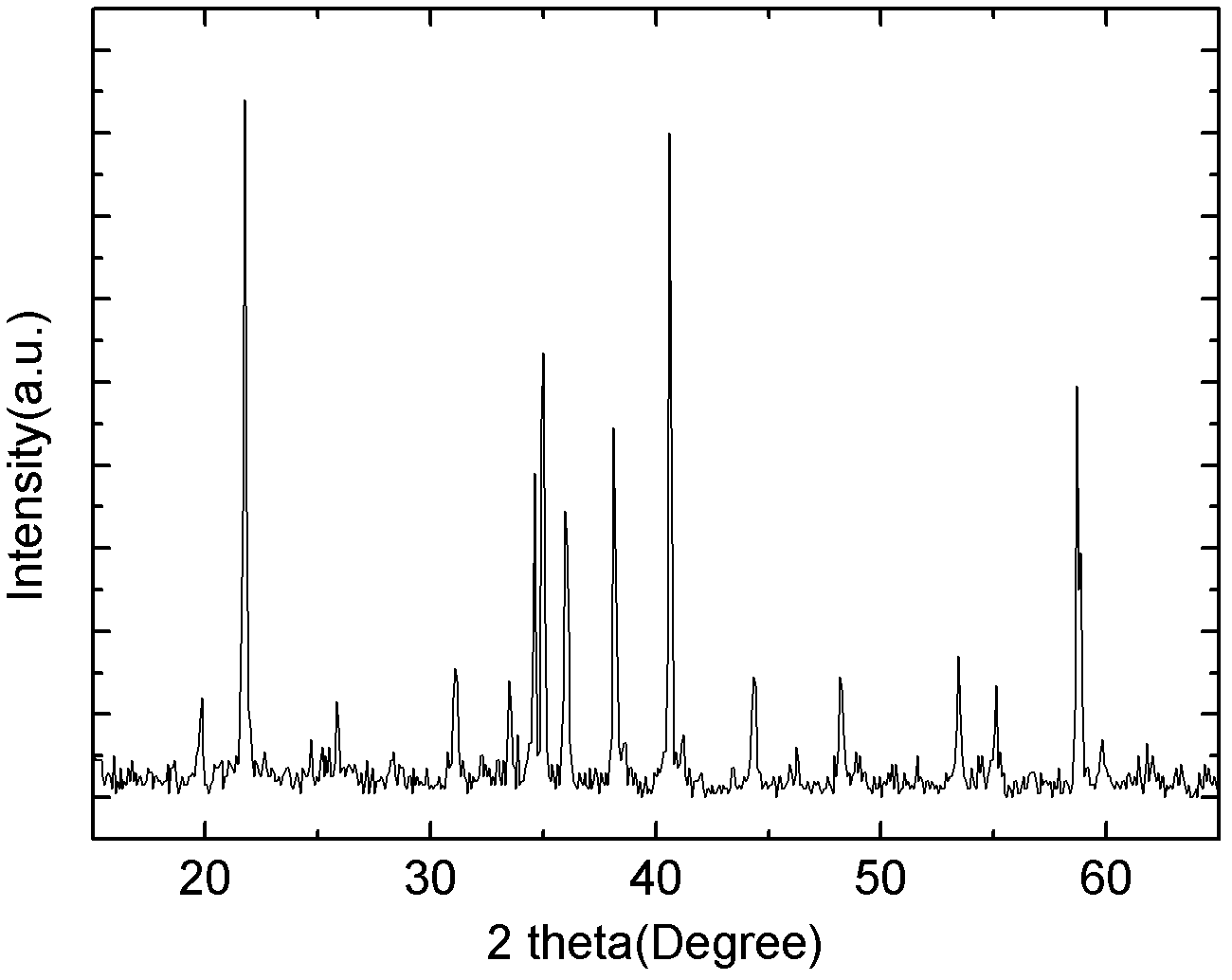

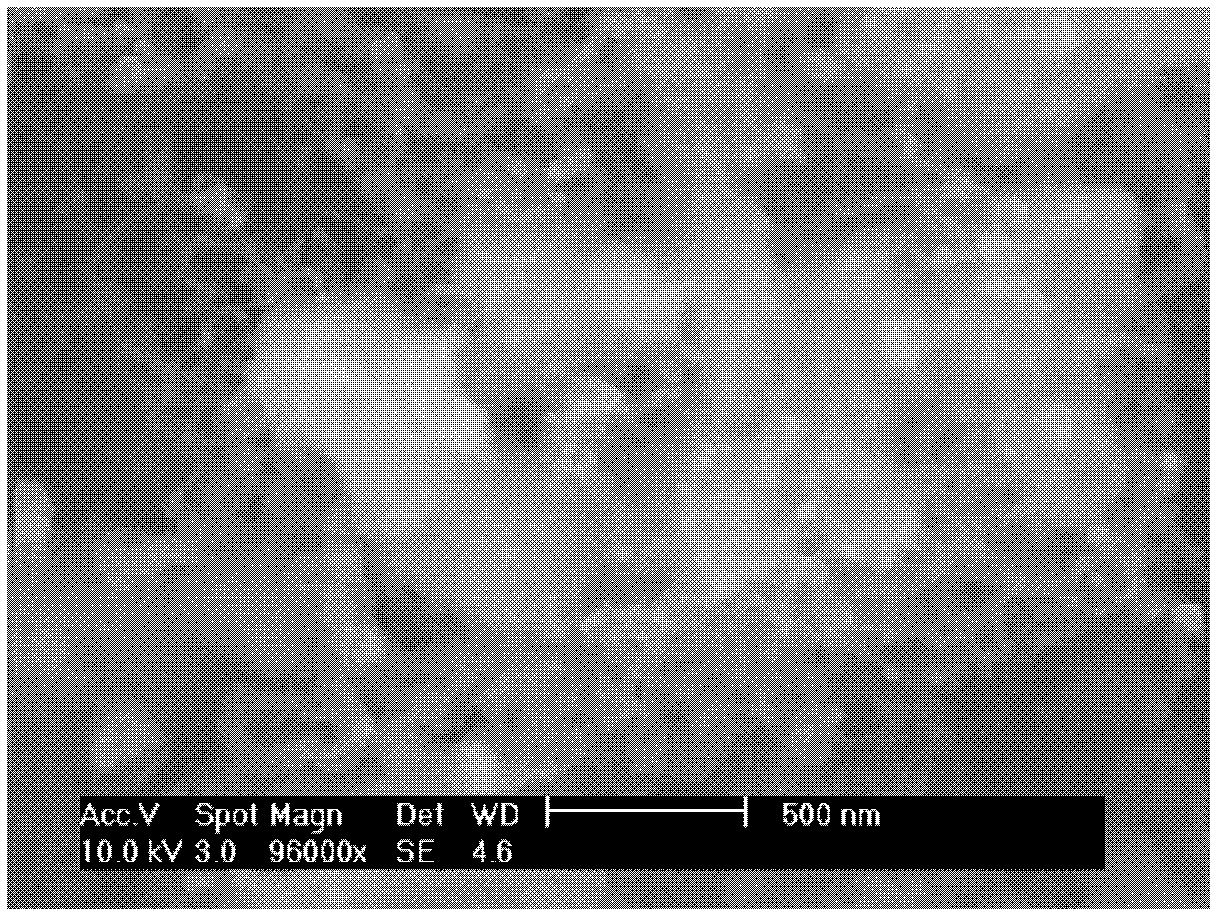

[0019] Dissolve 3.09g of boric acid, 3.45g of lithium nitrate and 17.9g of manganese nitrate in 100ml of distilled water, stir at room temperature for 2 hours to make the solution evenly mixed, then raise the temperature to 80°C, and evaporate the water in the solution while stirring until a gel is formed. The obtained colloidal substance is then dried in an oven at 120° C., ground and pulverized to obtain a mixed material. Next, under the protection of a mixed gas of hydrogen and argon with a volume ratio of 1:20, the temperature of the resulting mixture is raised to 750°C at a rate of 2°C per minute; then, the gas is replaced with The mixed gas of acetylene and argon was reacted at 750° C. for 8 hours; finally, it was naturally cooled to room temperature to obtain the desired carbon nanotube-coated lithium manganese borate cathode material. Such as figure 1 As shown, X-ray powder diffraction analysis showed that the obtained product was LiMnBO 3 , without any other impurit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com