Method for removing arsenic hydride in tail gas of iron making blast furnace by wet process

An iron-smelting blast furnace and wet purification technology, applied in chemical instruments and methods, separation methods, arsenate/arsenite, etc., can solve the problems of secondary pollution, complex preparation process, high catalyst regeneration cost, and achieve Low cost, good removal effect, simple effect of purification equipment and purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

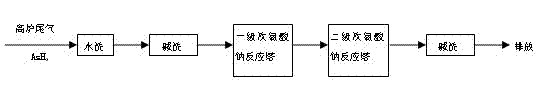

[0016] Under normal temperature and pressure and airtight conditions, take 4.8 kg of commercially available granular NaOH with a purity of 96%, add 87.36 kg of distilled water, mix well, and prepare a NaOH alkali cleaning solution with a mass percentage of 5%; store the 0.63 m 3 Cl 2 (equivalent to a mass of 2kg of chlorine gas) through a gas meter into 951.5kg of distilled water to make HClO, the ClO introduced in this step 2 Amount and distilled water mass ratio are 2:951.5, and the HClO content in the prepared solution is 1.5kg; Get the 5% NaOH solution of 46kg and the HClO solution that has prepared and mix uniformly to get NaClO solution, put into reaction tower for subsequent use, the HClO:NaOH=1:1 in the solution, the available chlorine content is 0.1%, and the pH of the solution is 7. The arsine content is 800mg / m 3 The iron-making blast furnace tail gas passes through water washing, alkali washing, primary sodium hypochlorite reaction tower and secondary sodium hyp...

Embodiment 2

[0019] Under normal temperature and pressure and airtight conditions, take 7.08kg of commercially available granular NaOH with a purity of 96%, add 60.89kg of distilled water, mix well, and prepare a 10% NaOH alkaline cleaning solution by mass percentage; 0.5m 3 (converted to chlorine gas with a mass of 1.6kg) of Cl 2 Pass the gas meter into 962kg of distilled water to make HClO, the introduced Cl 2 Amount and distilled water mass ratio are 1.6:962, and the HClO content in the prepared solution is 1.2kg; Get the 10% NaOH solution prepared by 34kg and the HClO solution that has been prepared and mix to get NaClO solution, put into reaction tower for subsequent use, In this solution, HClO:NaOH=1:1, the available chlorine content is 0.08%, and the pH of the solution is 9. The arsine content is 1200mg / m 3 The iron-making blast furnace tail gas passes through water washing, alkali washing, primary sodium hypochlorite reaction tower and secondary sodium hypochlorite reaction towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com