Method for electrochemical preparation of cadmium telluride semiconductor film under alkaline water phase condition

An alkaline condition, electrochemical technology, applied in the direction of chemical instruments and methods, semiconductor devices, circuits, etc., to achieve the effect of reducing corrosion, solving needle-like pores, and reducing interface state density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of CdTe Alkaline Precursor Deposition Solution

[0036] According to 0.005M tellurium dioxide (TeO 2 ), 0.005M cadmium sulfate (3CdSO 4 ·8H 2 O) and the amount of complexing agent nitrilotriacetic acid (NTA) of 0.005M. Put the three kinds of raw materials into a large beaker filled with 50mL deionized water. Adjust the pH to 7.8 and stir well to make the TeO 2 , cadmium sulfate and NTA are all dissolved and set aside;

[0037] (2) Electrochemical deposition of CdTe thin films

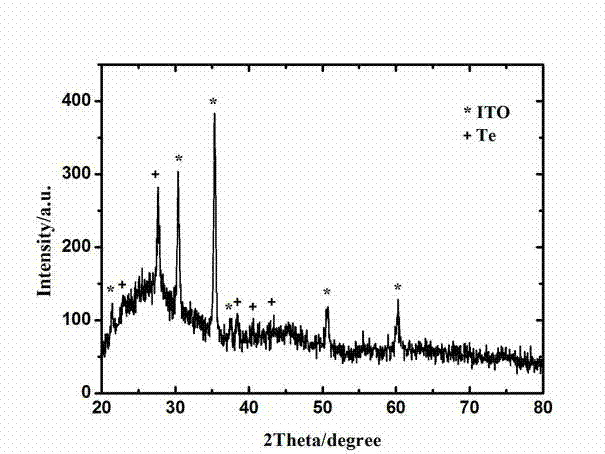

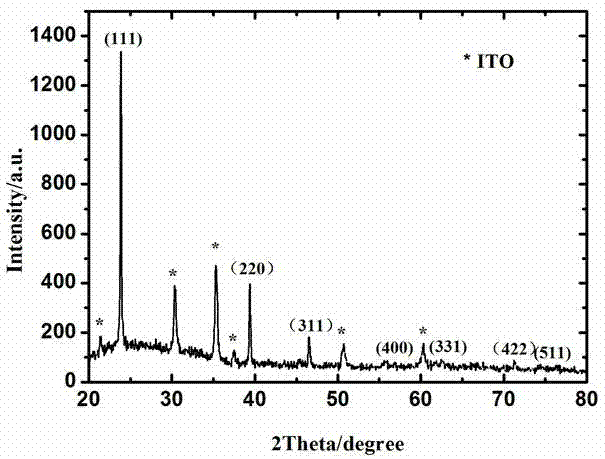

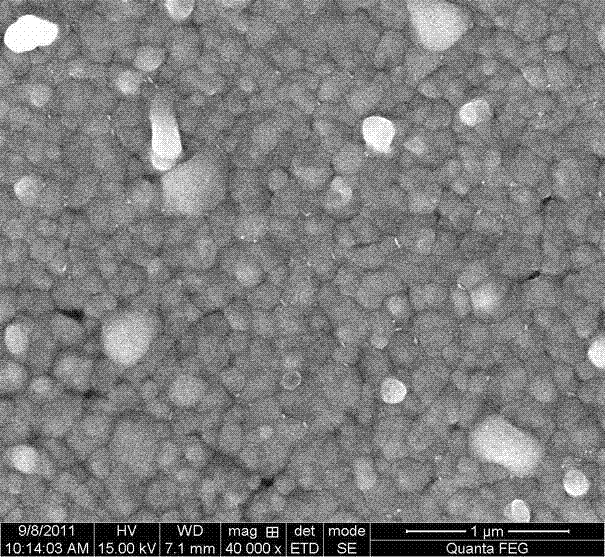

[0038] Put the cleaned ITO conductive glass in the alkaline precursor deposition solution prepared in step (1), and deposit it at 20°C for 10 minutes at the cathode potential of the -1.0V vs. HgO / KOH reference electrode, and take out the CdTe film. Rinse with deionized water and dry at 100 °C. XRD test results such as Figure 1a , containing a small amount of elemental Te;

[0039] (3) Post-processing of CdTe thin film

[0040]Transfer the CdTe film prepared in step (2) ...

Embodiment 2

[0042] (1) Preparation of CdTe Alkaline Precursor Deposition Solution

[0043] According to 0.001 M tellurium dioxide (TeO 2 ), 0.005M cadmium sulfate (3CdSO 4 ·8H 2 O) and 0.01 M of nitrilotriacetic acid (NTA) put the three raw materials into a large beaker filled with 50 mL of deionized water, the molar ratio of cadmium salt and complexing agent is 1:2, and the pH of the solution is adjusted to 8.4 , fully stirred to dissolve all, set aside;

[0044] (2) Electrochemical deposition of CdTe thin films

[0045] Put the cleaned ITO conductive glass in the CdTe alkaline precursor deposition solution prepared in step (1), and deposit it at 30°C for 20 minutes at the cathode potential of -1.1V vs. HgO / KOH reference electrode, and take out the CdTe film , washed with deionized water, and dried at 100 °C. The crystal structure of the obtained film is as Figure 4 As shown, there is only the diffraction peak of ITO, but no obvious CdTe peak;

[0046] (3) Post-processing of CdTe...

Embodiment 3

[0049] (1) Preparation of CdTe Alkaline Precursor Deposition Solution

[0050] According to 0.005M tellurium dioxide (TeO 2 ), 0.01M cadmium acetate (C 4 h 6 CdO 4 2H 2 O) and the amount of nitrilotriacetic acid (NTA) of 0.025M put the three raw materials into a large beaker filled with 50mL deionized water, the molar ratio of cadmium salt and complexing agent is 1:2.5, and the pH is adjusted to 8.7 , fully stirred to dissolve all, set aside;

[0051] (2) Electrochemical deposition of CdTe thin films

[0052] Put the cleaned ITO conductive glass in the CdTe alkaline precursor deposition solution prepared in step (1), and deposit it at 35°C for 30 minutes at the cathode potential of the -1.2V vs. HgO / KOH reference electrode, and take out the CdTe film , washed with deionized water, and dried at 100 °C. crystal structure and Figure 4 resemblance;

[0053] (3) Post-processing of CdTe thin film

[0054] Transfer the CdTe film prepared in step (2) to a rapid annealing fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com