Method for performing surface treatment on neodymium-iron-boron permanent magnet material by using nano ceramic

A permanent magnet material and nano-ceramic technology, which is applied to the device for coating liquid on the surface, special surface, pretreatment surface, etc., can solve the problem of affecting the service life of NdFeB permanent magnet materials, reducing product stability and reliability, The NdFeB alloy has poor corrosion resistance and other problems, which can save the surface adjustment process, reduce the cost and shorten the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

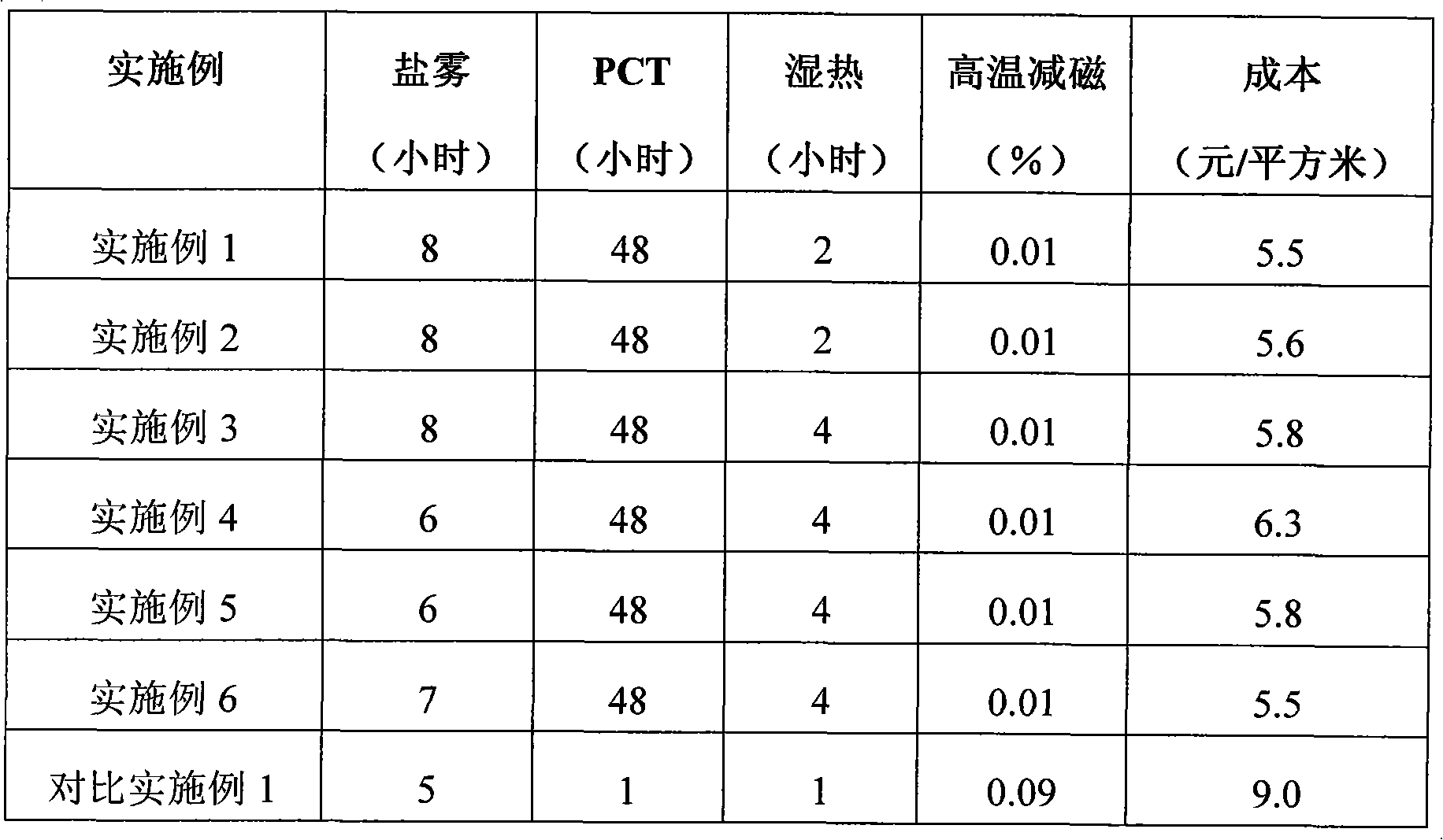

[0025] Will 2.3 kilograms of 18mm sintered NdFeB permanent magnet materials are polished in a vibration mill for 2 hours. Sodium phosphate 20g / liter, sodium carbonate 10g / liter, sodium hydroxide 10g / liter degrease after degreasing, pickling in 1% nitric acid to remove surface oxide, washing with water, nano-ceramic treatment. Wherein the main film-forming agent is 15 grams of E-51 epoxy resin, 25 grams of methyl isobutyl ketone, 50 grams of nano silicon dioxide, and 5 grams of triethanolamine are mixed together for subsequent use. Cured at 120°C for 1.5 hours. The coating thickness is 20 nm. Then carry out salt spray test, PCT test, damp heat test and high temperature demagnetization measurement. It can be seen that the coating has good adhesion, the cross-cut test is qualified, and the anti-corrosion performance is shown in Table 1.

Embodiment 2

[0027] Will 2.3 kilograms of 18mm sintered NdFeB permanent magnet materials are polished in a vibration mill for 2 hours. Sodium phosphate 20g / liter, sodium carbonate 10g / liter, sodium hydroxide 10g / liter degrease after degreasing, pickling in 1% nitric acid to remove surface oxide, washing with water, nano-ceramic treatment. Wherein the main film-forming agent is 25 grams of E-44 epoxy resin, 15 grams of methyl ethyl ketone peroxide, nano-alumina 65, and 20 grams of diethanolamine are mixed together for later use. Cured at 120°C for 1.5 hours. The coating thickness is 20 nm. The coating has good adhesion and is qualified in the scratch test, and the anti-corrosion performance is shown in Table 1.

Embodiment 3

[0029] Will 2.3 kilograms of 18mm sintered NdFeB permanent magnet materials are polished in a vibration mill for 2 hours. Sodium phosphate 20g / liter, sodium carbonate 10g / liter, sodium hydroxide 10g / liter degrease after degreasing, pickling in 1% nitric acid to remove surface oxide, washing with water, nano-ceramic treatment. The main film-forming agent is 20 grams of E-51 epoxy resin, 2 grams of methyl isobutyl ketone, 20 grams of methyl ethyl ketone peroxide, 10 grams of nano-silica, 50 grams of aluminum oxide, 5 grams of triethanolamine, and 12 grams of diethanolamine Mix together and set aside. Cured at 120°C for 1.5 hours. The coating thickness is 23 nm. Then carry out salt spray test, PCT test, damp heat test and high temperature demagnetization measurement. It can be seen that the coating has good adhesion, the cross-cut test is qualified, and the anti-corrosion performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com